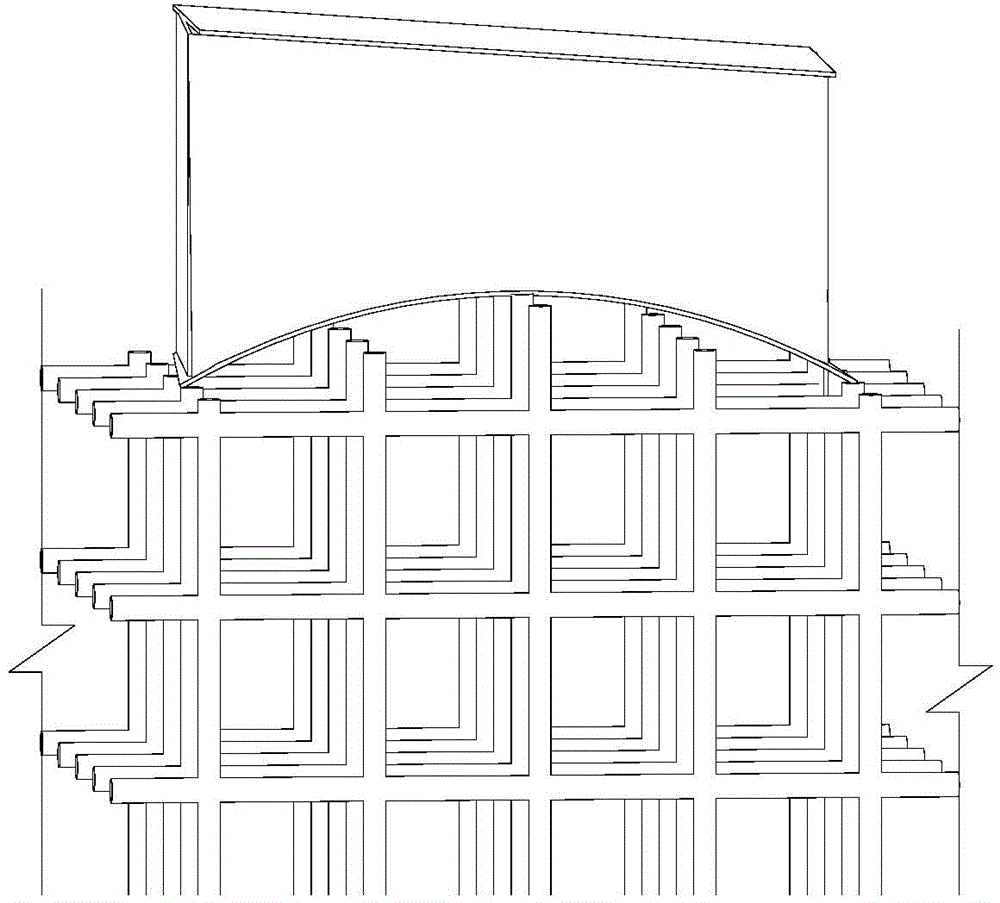

Overall horizontal assembly method for box-type steel arched girder

A technology of horizontal assembly and alignment method, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve the problems of long total construction period, poor stability of a single segment, high cost, etc., and achieves short construction period and less site occupation , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0038] A method for integral horizontal alignment of box-type steel arch beams, comprising the following steps:

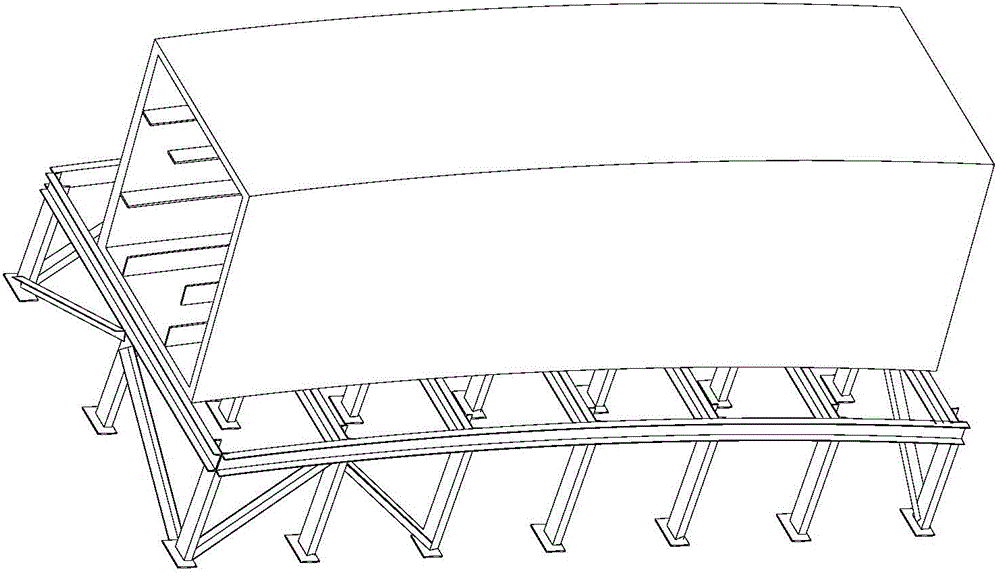

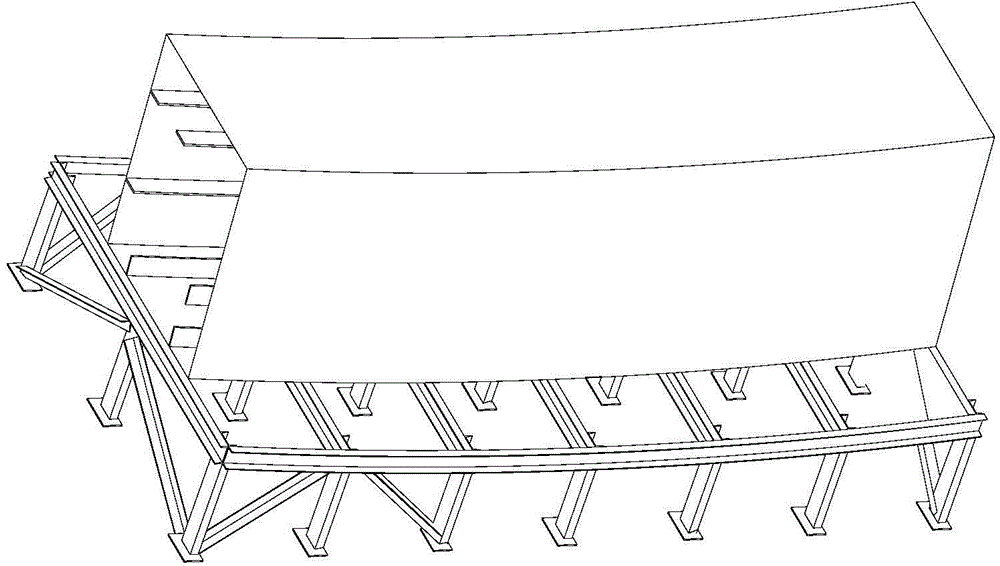

[0039] ①In order to facilitate transportation, before assembling, place the drawings as follows Figure 4 The overall structure of the box-type steel arch beam shown is divided into Image 6 several segments shown, such as Figure 9 As shown, the high-side web unit 6 in place temporarily fixes the high-side web unit first segment 16 and the high-side web unit second segment 17;

[0040] ② Then, if Figure 7 and Figure 8 As shown in the figure, the frame 1 for the pair of box-type steel arch beams is made, and the position of the diaphragm of the box-type steel arch beam and the positioning points of the interface positions of each segment are marked 15;

[0041] ③ After the box-type steel arch beam group pairing frame 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com