Entire loading and transporting technology and equipment for portal crane

A technology of portal cranes and cranes, which is applied in the direction of cranes, trolley cranes, transportation and packaging, etc., can solve the problems of high cost and wasteful use of the owner's site, and achieve the effect of saving hoisting costs, saving installation sites and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following are embodiments of the present invention:

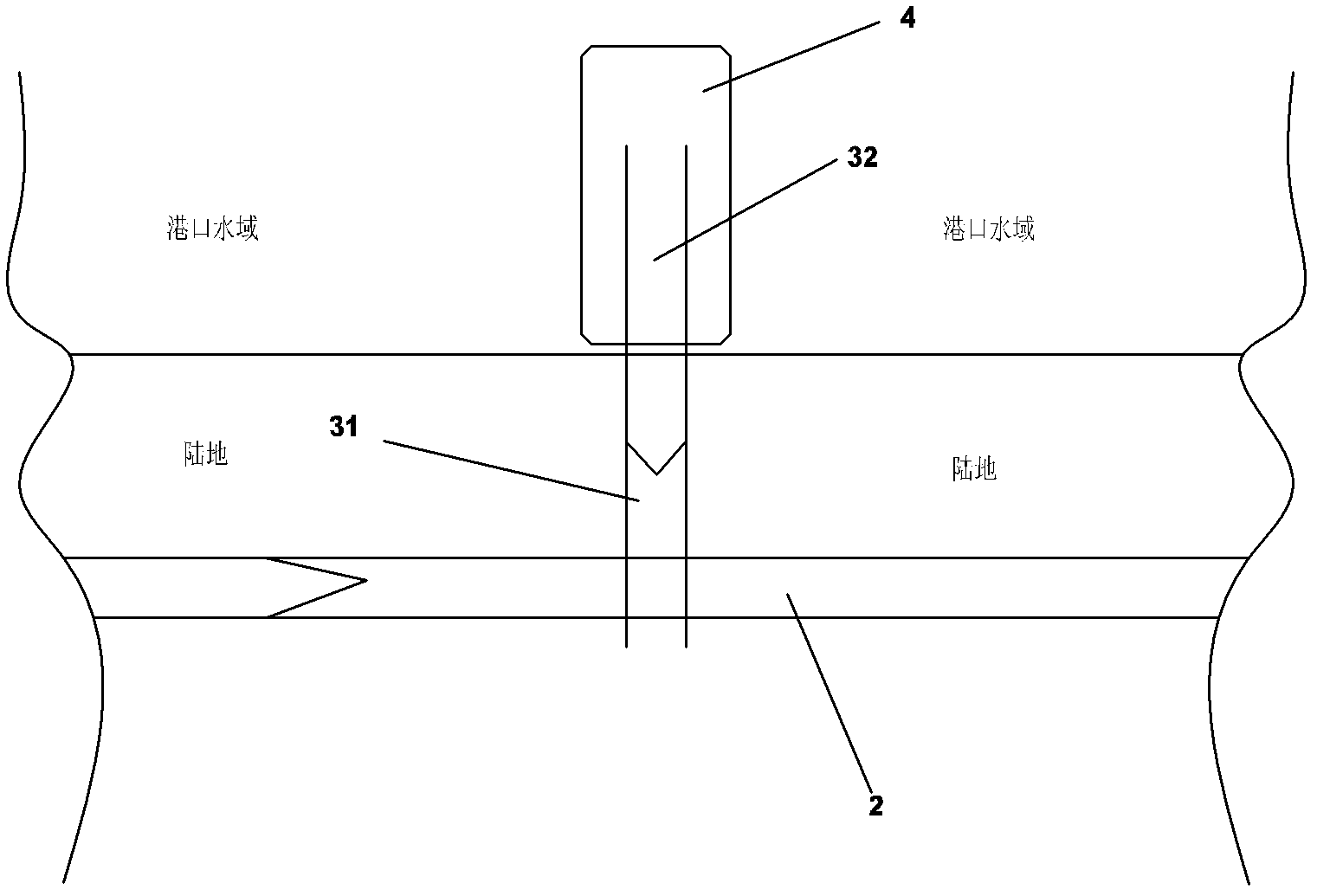

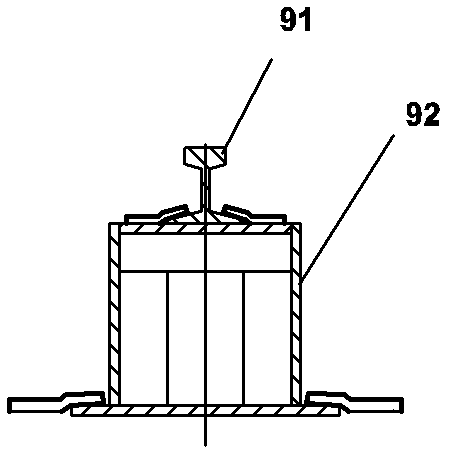

[0049] Between the balance beam of the running gear 11 of the portal crane 1 of the present invention and the portal frame 12 of the portal crane 1, be connected with a vertical rotating shaft 13 (as Figure 5 , Figure 6 shown), the mast 12 is fixedly provided with four jack support structures 121 and four lifting lugs 122, and two jack support structures 121 and two lifting lugs 122 are respectively arranged on both sides of the mast 12 (such as Figure 6 shown); the ground is provided with a running track 2, the top of the running track 2 is provided with a temporary track 31 of the land part that is 90° with the running track 2, and the ship 4 is provided with a temporary track 32 on board the ship that is horizontal with the temporary track 31 of the land part (Such as figure 1 shown), the two ends of the movable hook 5 are respectively hinged on the temporary track 31 of the land part and the temporary tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com