Production technology of wear-resistant composite pipe filled with adhesive cement

A production process and technology for composite pipes, which are applied to tubular items, household appliances, other household appliances, etc., can solve the problems that the quality cannot continuously reach the same standard, the production cycle of wear-resistant composite pipes is long, and the wear-resistant materials are easy to shift. Achieving the effect of avoiding undetectable hidden dangers of quality, shortening production cycle and saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

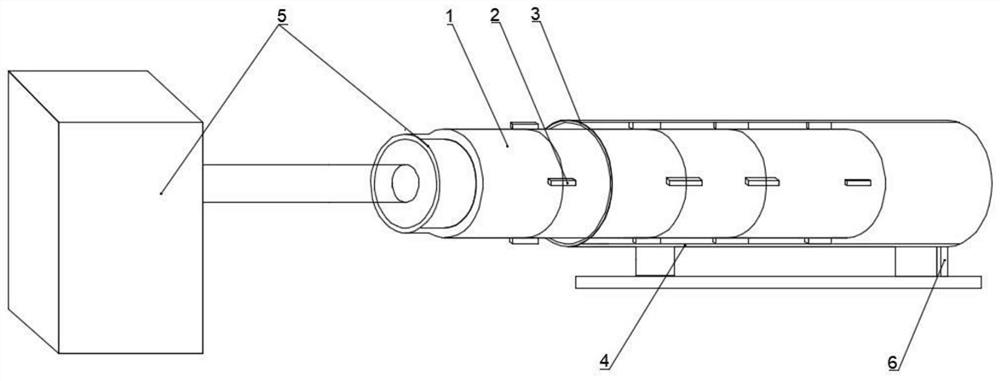

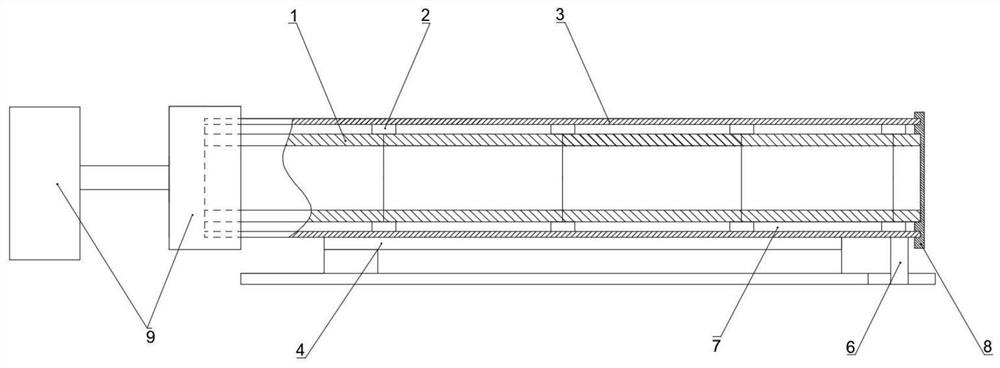

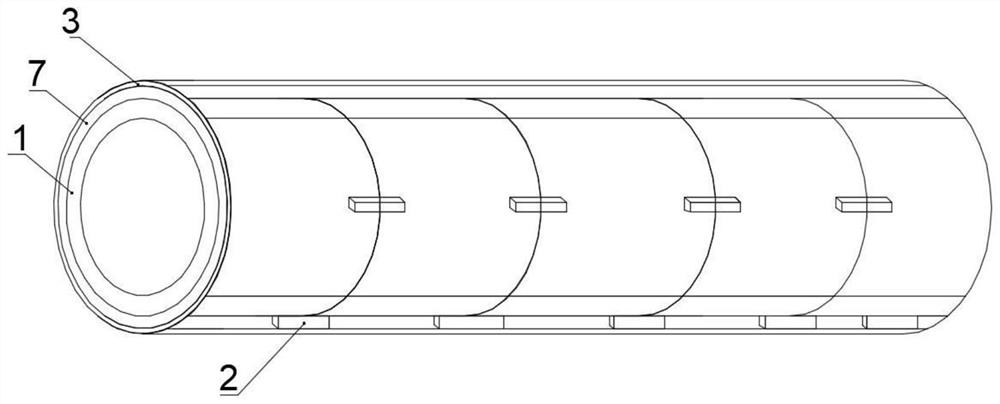

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

[0031] The production process of the wear-resistant composite pipe in the prior art is horizontal pipe entry and vertical filling with adhesive mortar. The specific production steps are: pipe making, pipe entry, sealing one end, fixing the sealing end, hanging and moving, making glue Bonding grout, gravity grouting, maintenance, hoisting and laying flat, inspecting grout voids, repairing grout voids, end repairing, composite pipe outer surface treatment, and finished products.

[0032] The production process of the wear-resistant composite pipe of the present invention is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com