Segmented mounting method for square raw coal hopper

An installation method and raw coal scuttle technology, applied in the field of power plant construction, can solve the problems of excessive use of mechanical shifts, heavy workload of scaffolding, and many butt welding points, and achieve saving of large mechanical shifts, reduction of full scaffolding, and better control The effect of size deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

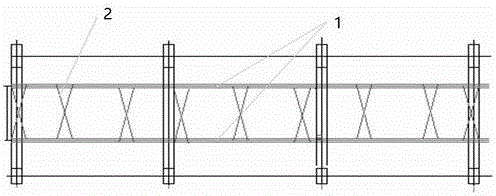

[0041] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. The invention discloses a segmented installation method of a square raw coal scuttle. The installation method includes the following steps:

[0042] 1) Raw coal scuttle production combination, including:

[0043] 11) Each segment of the coal hopper wall board shall be cut according to the lofting size of the drawing, and the number of segments shall be at least three;

[0044] 12) After the cutting material is cut and leveled, the assembly is carried out. After the assembly of the single piece is completed, the size is checked to confirm that it is correct, and then the reinforced steel is welded;

[0045] 13) After the butt welding of the coal bucket wall plate is completed, the segmented cylinder assembly is carried out;

[0046] 14) After the segmented cylinder is assembled, a well-shaped temporary reinforcement support is made inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com