Supporting plate for flat membrane elements as well as flat membrane elements and flat membrane components

A support plate and flat membrane technology, applied in the direction of membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of water flux drop, membrane surface clogging, insufficient rigidity, etc., to reduce the diversion process, span The effect of uniform membrane pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

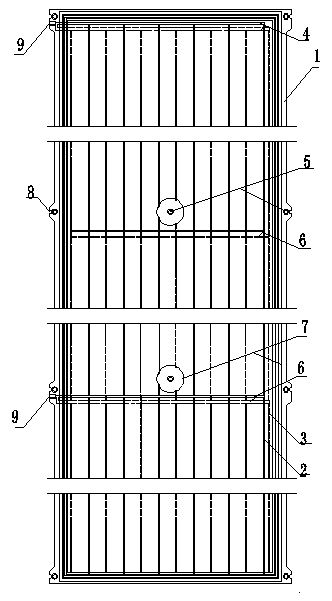

[0034] Embodiment 1: see figure 1 , the support plate 1 for the flat membrane element is made of plastic with a height of 1.8 meters, a width of 0.5 meters, and a thick 3.5mm flat plate with the prior art. At the upper end of the longitudinal diversion groove, there is a horizontal direction diversion groove 4 that is staggered horizontally from the width to the outermost longitudinal diversion groove, and the middle is 40% of the height and 75% of the height from top to bottom, and each has a horizontal to the width of the outermost longitudinal diversion groove The lateral positive and negative of groove staggers diversion groove 6, and each horizontal diversion groove one end up and down respectively has water nozzle 9. The front and back sides of the support plate have three rows of same positions on both sides and in the middle, and the circular bosses 5 protruding from the plate surface are arranged in phases. The height is determined by 1 / 2 of the usual minimum spacing,...

Embodiment 2

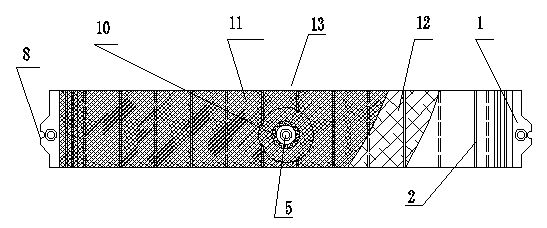

[0035] Example 2: see figure 2 , using embodiment 1 support plate 1, the same as the membrane element of the prior art, the front and back surfaces are respectively flat covered with diversion non-woven fabric 12 and flat microporous membrane 11, the diversion cloth and flat microporous membrane are placed on the boss of the support plate The position opening exposes the boss 5 . The welding plane 9 between the opening ring edge of the two-sided flat microporous membrane and the outer ring of the boss on the support plate surface adopts existing technologies such as high-frequency welding to form a closed circle 10, which is also welded with the prior art flat film and the surrounding surface of the support plate Closed, so that the microporous membrane surface and the support plate form a closed filtration space to form a flat membrane element 13 .

Embodiment 3

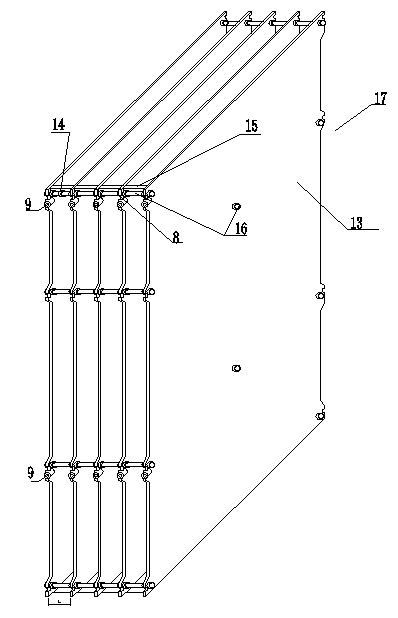

[0036] Embodiment 3: see image 3 , 5 pieces of flat membrane elements 13 of Embodiment 2 are arranged side by side according to the combination of the bosses, and the positioning pins 16 pass through the middle holes of the circular bosses 5 on both sides (width) to fix and compress, and the gap width of the interphase membrane elements 13 Both sides are closed by side sealing strips 15 to form a combined membrane element 17 . When assembling, if the distance L between adjacent membrane elements needs to be widened, widening spacers 14 can be added on each boss.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com