Protective frame special for construction of building main body

A technology of building main body and protective frame, which is applied in the direction of building, building structure, scaffolding supported by house structure, etc., can solve the problems of complicated operation, increased difficulty, inconvenient building construction, etc. Ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

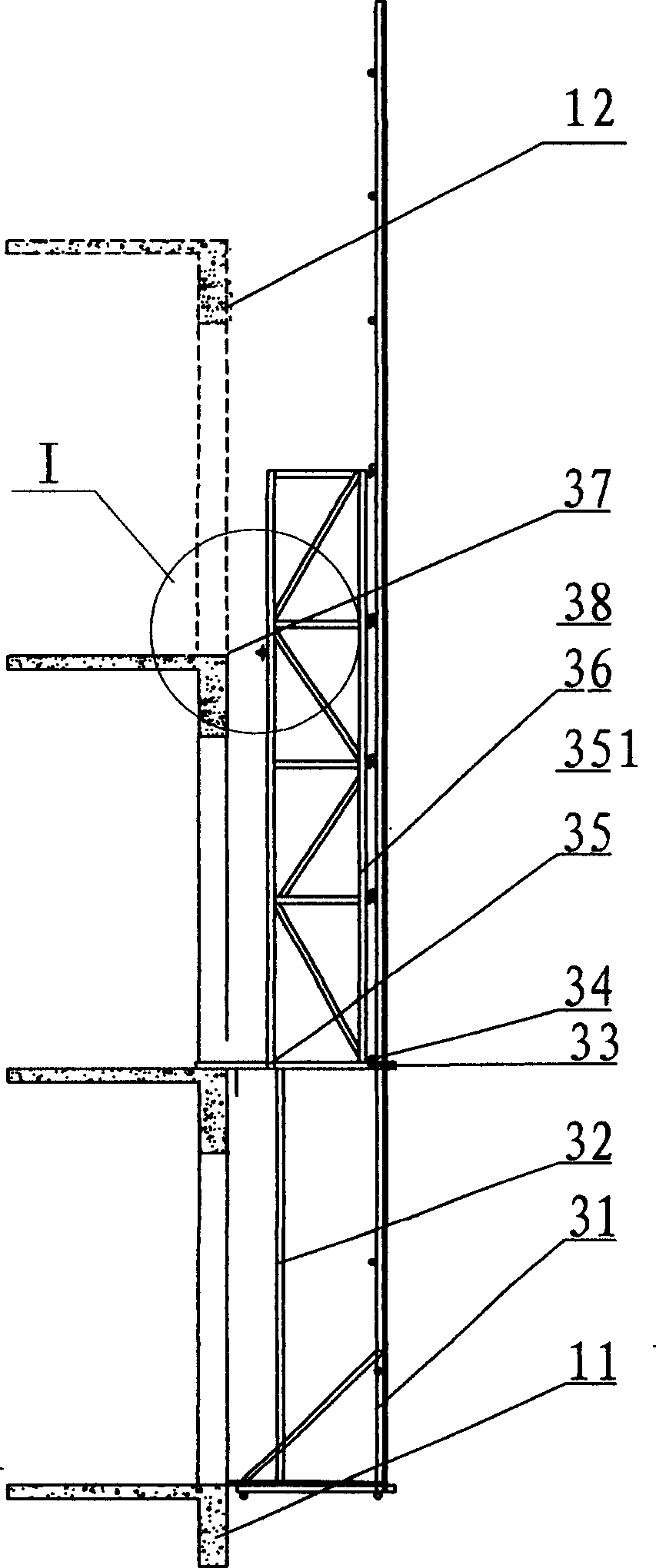

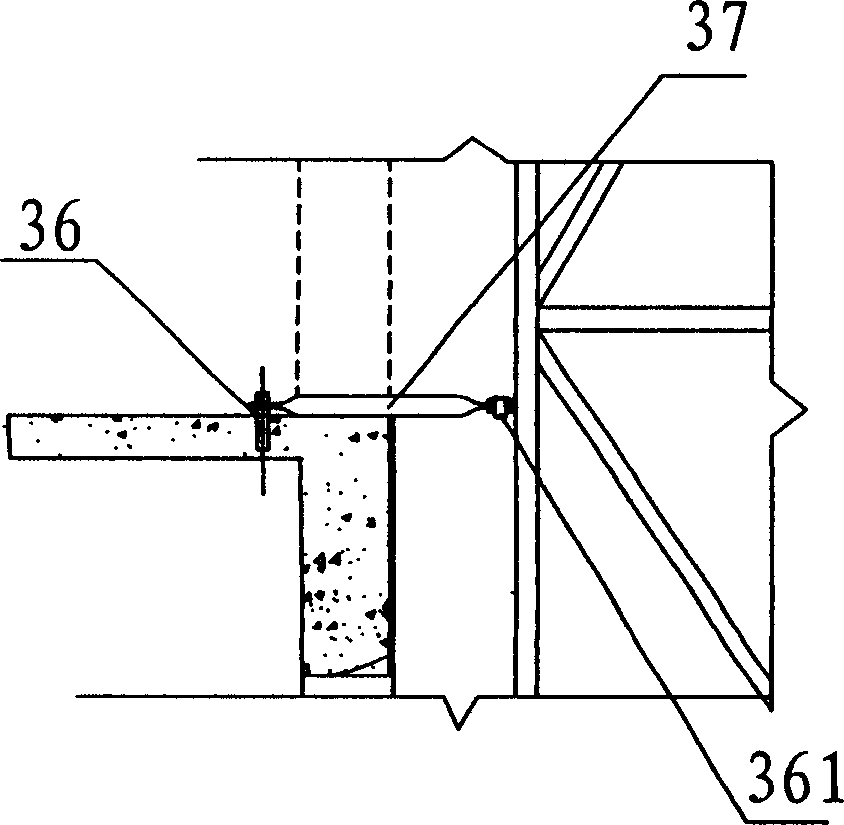

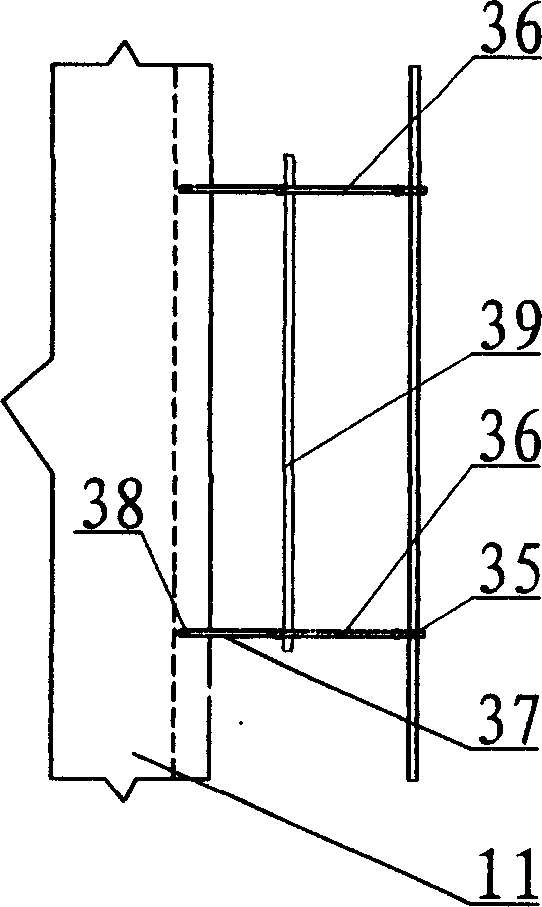

[0041] Such as figure 1 As shown, in this embodiment, the single-row frame body 31 of the protective frame has a height of three and a half buildings, and a group of large crossbars 33 on the inner side (close to the building side) are connected to the truss 36 by fasteners 34 Of course, it can also be connected in other forms such as bolts and pressing plates, but because the fastener is a general product for building construction, it is preferably used as a connecting piece, the same below. Such as Figure 1-Figure 2 As shown, the truss 36 is integrally welded with a fixed leg 35 , and the horizontal tie rod 37 is hingedly connected to the truss 36 through a pin 361 . The height of the truss 36 is one and a half stories high, and its connection position is located in the middle and upper part of the frame body; the unit length of the protective frame is 2m-6m, and two trusses are provided, such as image 3shown. A latch 38 is pre-embedded on the building floor. The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com