Aluminum alloy space grid structure slab rib node

A technology of space grid and structural plate, applied in the direction of building structure, construction, etc., can solve the problems of safety and economy that cannot be realized, and achieve the effects of ensuring safety and construction quality, improving rigidity and bearing capacity, and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

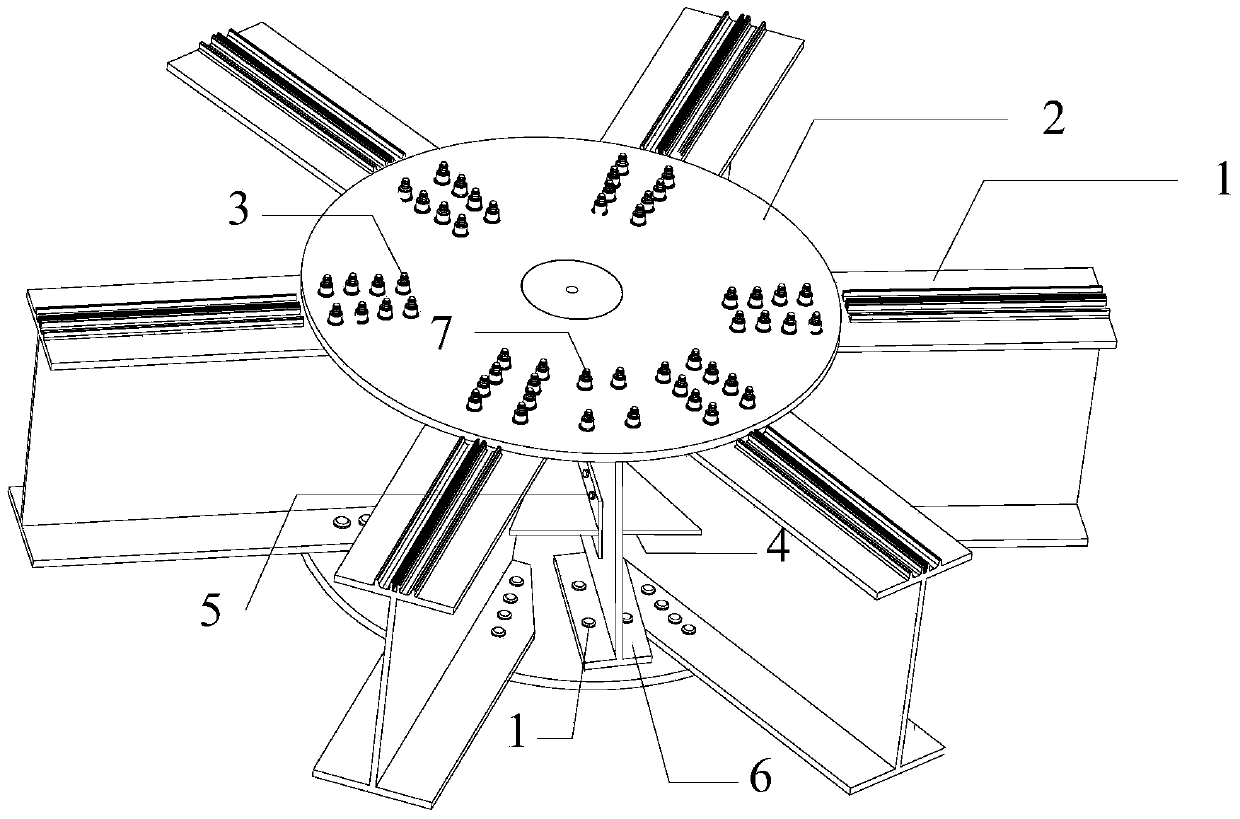

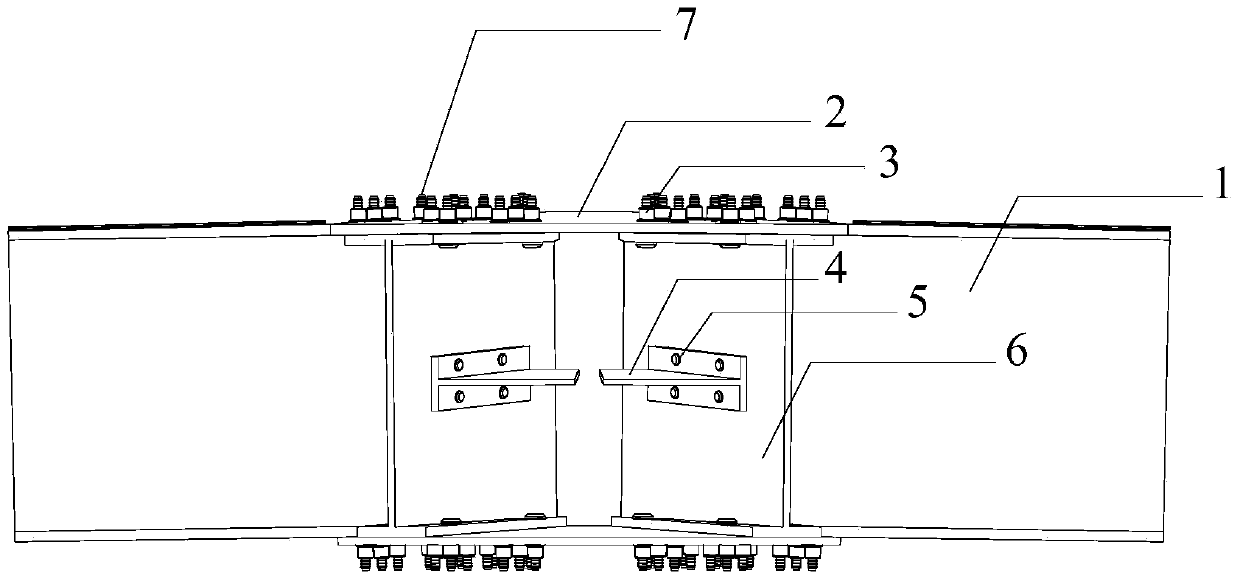

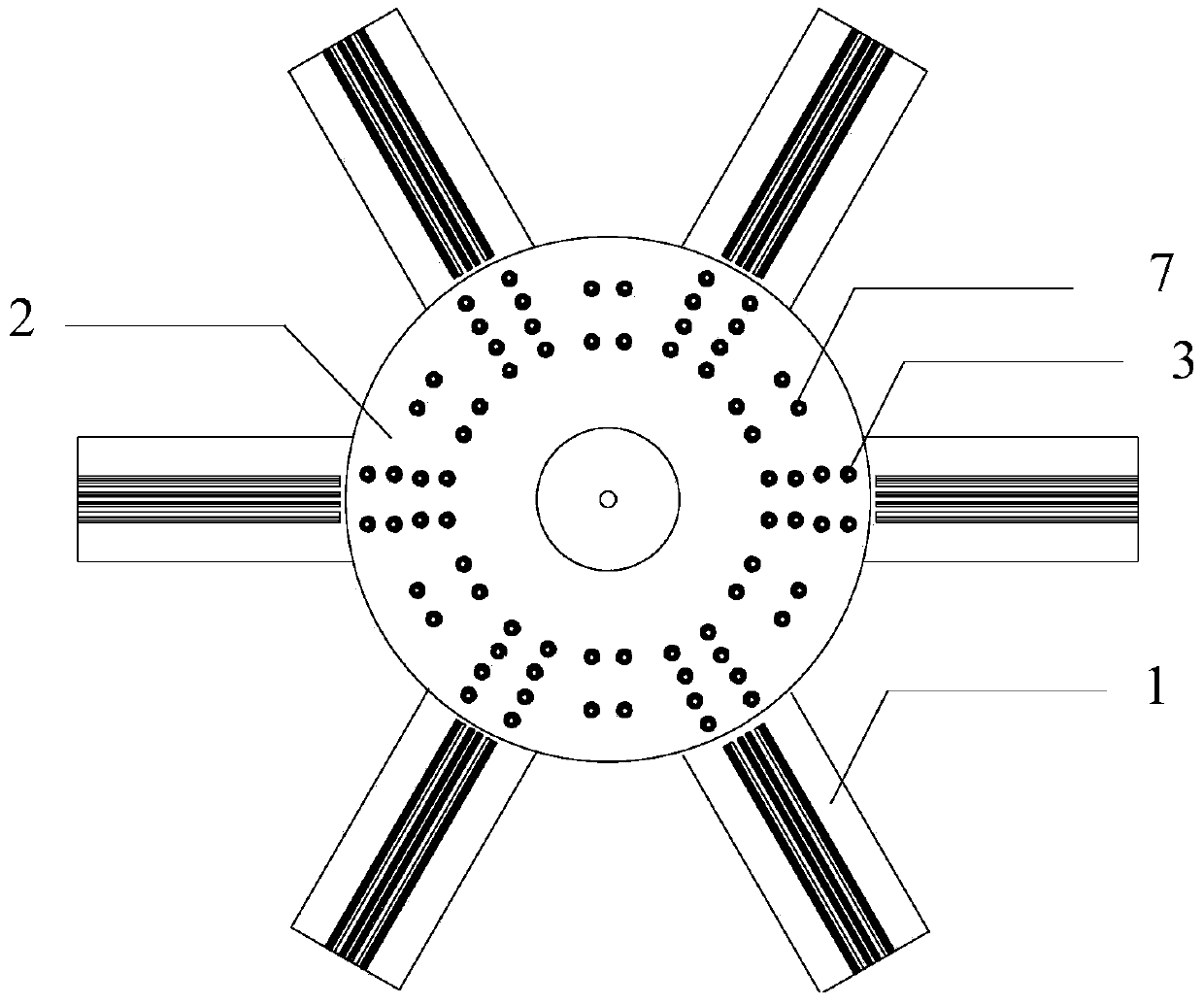

[0018] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0019] see Figure 1 to Figure 5 , an aluminum alloy space grid structure plate rib joint, including two upper and lower aluminum cover plates 2 arranged parallel to each other and at least two H-shaped aluminum rods 1 fixed between them through the first bolt 3, in the relative An H-shaped aluminum vertical rib 6 is arranged between two adjacent H-shaped aluminum rods 1, and the upper and lower ends of the H-shaped aluminum vertical rib 6 are respectively connected to the corresponding aluminum cover by the second bolt 7. Board 2 is fixed. The setting of the H-shaped aluminum vertical ribs 6 can improve the out-of-plane stiffness of the nodes.

[0020] In this embodiment, in order to improve the in-plane rigidity of the join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com