Lining member quasi-static test apparatus and lining member quasi-static test method

A technology of test device and test method, which is applied in the direction of measuring device, test material strength by applying repetitive force/pulsation force, instrument, etc., can solve the problems that there is no quasi-static test device for lining components, and achieve the expansion of model test method, Easy to operate, clear force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

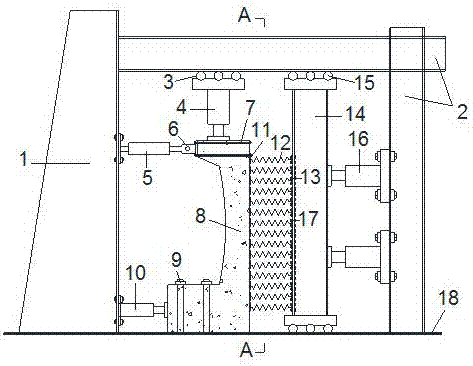

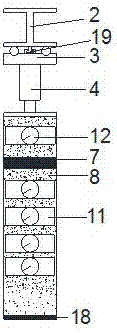

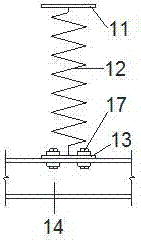

[0031] Embodiment 1: as Figure 1-3 Shown: a pseudo-static test device for lining components, including a reaction device, a loading device, a lining component, and a surrounding rock simulation system; a pseudo-static test device for a lining component, including a reaction device, a loading device, a lining component, Surrounding rock simulation system;

[0032] The reaction force device includes a reaction force wall 1 and a reaction force steel frame 2, the reaction force steel frame 2 is composed of a crossbeam and a vertical pillar, and the crossbeam is fixed between the reaction force wall 1 and the vertical pillar;

[0033] Described static force loading device comprises sliding bearing 3 and vertical jack 4, and described sliding bearing 3 is positioned at reaction force steel frame 2 beam below and is fixed on the beam by slide rail 19, and described vertical jack 4 upper end and sliding The supports 3 are connected, and the lower part is closely attached to the lin...

Embodiment 2

[0036] Example 2: The reaction force steel frame is welded by HW300×300 steel, the steel column is 3m high, the steel beam is 3m long, the reaction force wall 1 and the reaction force steel frame 2 are connected by M20 anchor bolts, and the steel column is M20 The bolts are fixed on the ground 18 to form a counter force device;

[0037] For the realization of the static loading device, the sliding support 3 is located under the upper crossbeam of the reaction force steel frame 2 and is fixed on the crossbeam through the slide rail 19, and an embedded steel ball is placed between the sliding support 3 and the crossbeam to realize the support of the support. move. It is beneficial to apply eccentric loads with different eccentric distances; the dynamic loading device adopts the MTS actuator 5 fixed on the reaction wall 1 to realize the application of reciprocating load, and then connects the horizontal connecting rod 6 and the bolt 7, and the bolt 7 clamps the lining member The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com