Honeycomb sandwiched sound absorbing and noise reducing structure filled with porous fibers and method of preparing same

A porous fiber, honeycomb interlayer technology, applied in the field of sound absorption and noise reduction, can solve the problems of poor structural performance and poor bearing effect, and achieve the effect of solving the problem of insufficient bearing capacity, excellent sound absorption performance, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

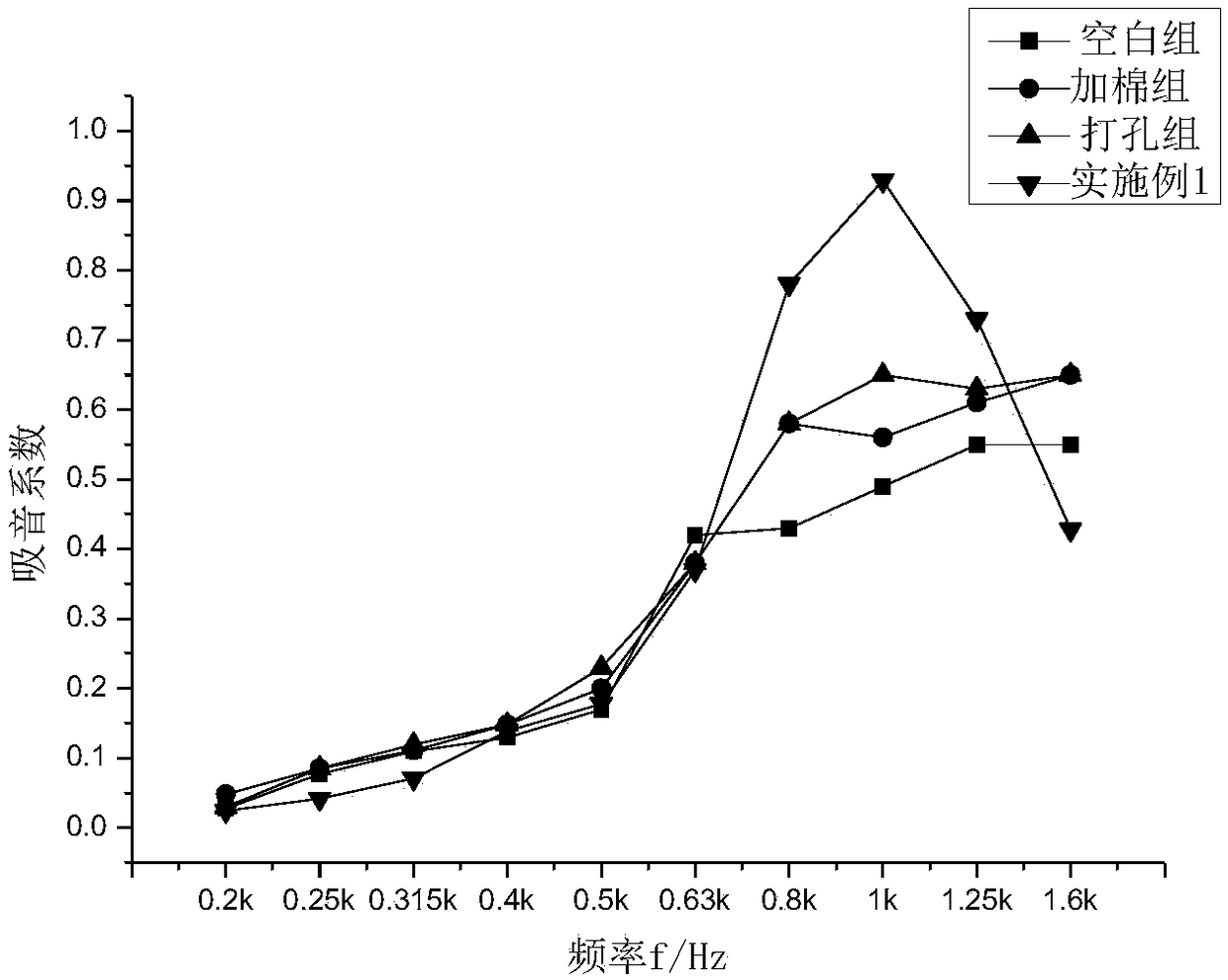

Embodiment 1

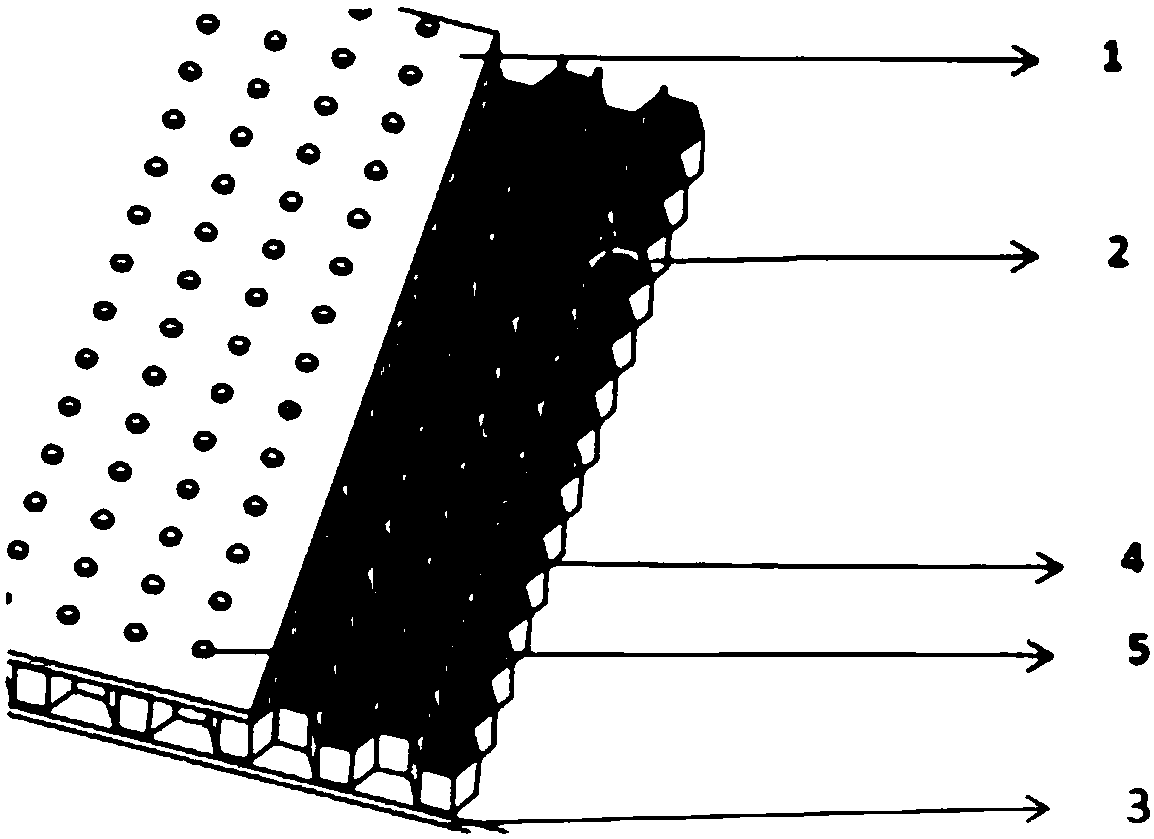

[0025] Such as figure 1 As shown, it is a honeycomb sandwich sound-absorbing and noise-reducing structure filled with porous fibers provided in this embodiment. The honeycomb sandwich sound-absorbing and noise-reducing structure includes an upper skin 1 , a honeycomb sandwich core 2 and a lower skin 3 . The honeycomb core 2 is sandwiched between the upper skin 1 and the lower skin 3 . Each cell of the honeycomb core 2 is filled with PP / PET bicomponent porous fibers 4 , and a plurality of through holes 5 are opened on the upper skin 1 .

[0026] In this embodiment, the honeycomb structure of the honeycomb sandwich core 2 is a regular hexagonal AC-NH meta-aramid paper honeycomb, and its density is about 32kg / m 3 , the cell side length is 5.5mm, and the thickness is 15mm. The mass percentage of PP in the PP / PET bicomponent porous fiber is 20%-80%, the diameter of PP is 5-8 μm, and the diameter of PET is 3-6 μm. The bulk density of the porous fiber is 0.01g / cm 3 -0.05g / cm 3 ....

Embodiment 2

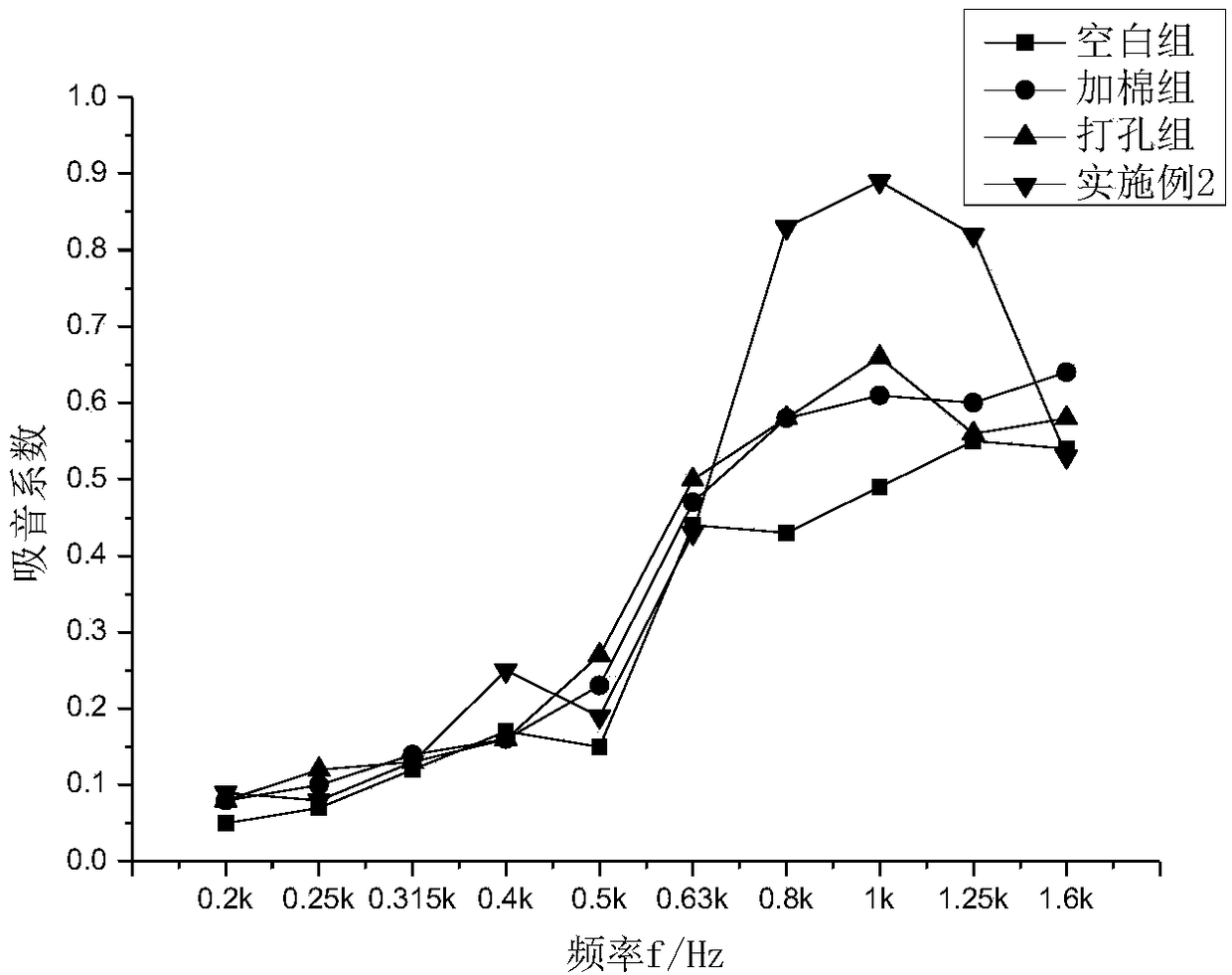

[0037] This embodiment is roughly the same as Embodiment 1, except that the bulk density of the porous fiber filling is changed, and the bulk density of the porous fiber filling becomes 0.03g / cm 3 .

[0038] image 3 It is the sound absorption coefficient figure actually tested in this embodiment. In this embodiment, the sound absorption coefficient NRC of the honeycomb sandwich sound-absorbing structure can reach a maximum of 0.89 at 1KHz, and the effective sound-absorbing bandwidth is 0.7-1.6KHz. This embodiment can achieve a good sound absorption effect in the middle and high frequency bands with a relatively low thickness.

[0039] The invention has the characteristics of simple structure, light weight and high strength, and excellent sound absorption performance at medium and high frequencies, so it has very wide application prospects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com