Solid waste foundation grouting material suitable for reinforcing bearing capacity of existing pile foundation and preparation method

A technology of grouting material and bearing capacity, which is applied in the fields of pile foundation reinforcement engineering, building material preparation, and comprehensive utilization of industrial solid waste, and can solve the problem of inability to efficiently improve the side friction resistance and ultimate bearing capacity of the original pile foundation, pile-soil The low strength of the cemented interface restricts the high-efficiency reinforcement of the pile foundation and other issues, and achieves the effects of saving preparation costs, high compressive strength, and alleviating ecological and environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

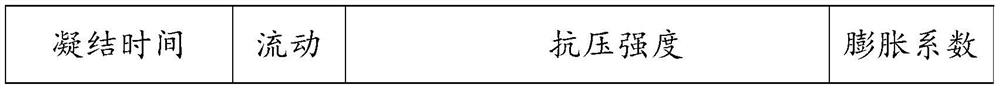

Embodiment 1

[0035] The composition and mass ratio of the solid waste base grouting material suitable for the reinforcement of existing pile foundation bearing capacity disclosed in this example: 50 parts of Bayer process red mud, 40 parts of steelmaking pig iron slag, 25 parts of limestone tailings, desulfurized gypsum 15 parts, 40 parts of activator. Activator components and mass ratio are 25 parts of potassium hydroxide aqueous solution with a concentration of 16%, 20 parts of carbide slag, and 15 parts of quicklime. The admixture components and mass ratio are 8 parts of 8604 low-alkali quick-setting agent, 11 parts of alunite expansion agent, 8 parts of calcium chloride, 4 parts of polyacrylamide, and 8 parts of sodium lignosulfonate.

[0036] Corresponding preparation method: Stir the red mud, blast furnace slag, and limestone tailings synergistically desulfurized gypsum ground to a specific specific surface area for 120s in a dry state, add the corresponding proportion of activator a...

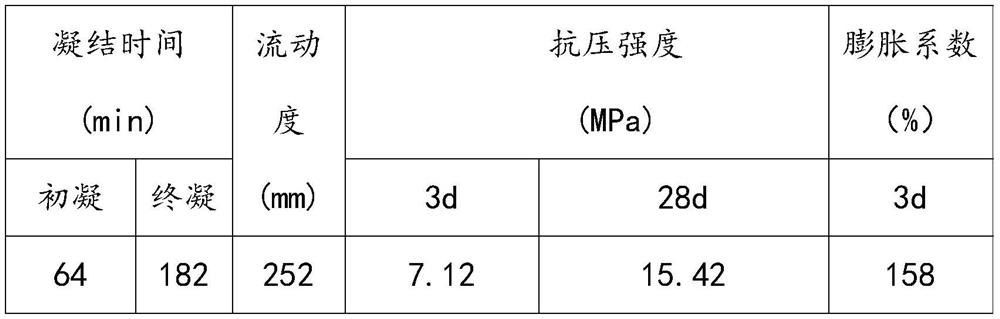

Embodiment 2

[0040] The composition and mass ratio of the solid waste base grouting material suitable for the reinforcement of existing pile foundation bearing capacity disclosed in this example are: 70 parts of Bayer process red mud, 20 parts of special pig iron slag, 10 parts of limestone tailings, and desulfurized gypsum 10 parts, 15 parts of activator, 10 parts of admixture. Activator components and mass ratios are 15 parts of potassium hydroxide aqueous solution with a concentration of 8%, 10 parts of carbide slag, and 5 parts of quicklime. The admixture components and mass ratio are 4 parts of 782-type low-alkali quick-setting agent, 6 parts of calcium sulfoaluminate expansion agent, 6 parts of sodium nitrite, 1 part of carrageenan, and 2 parts of casein.

[0041] The preparation method corresponding to this example: stir red mud, blast furnace slag, limestone tailings and desulfurized gypsum in a dry state for 120s in a dry state, add corresponding proportion of activator and admixt...

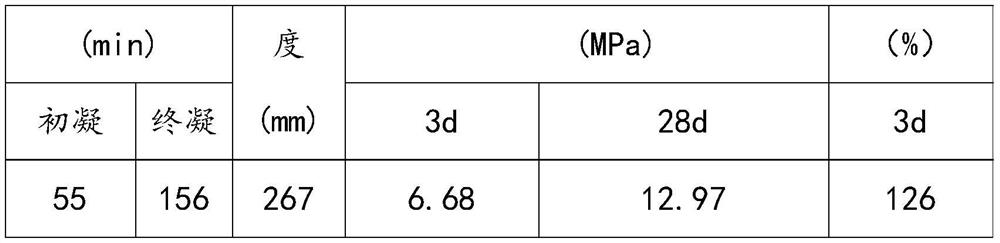

Embodiment 3

[0044] The composition and mass ratio of the solid waste base grouting material suitable for the reinforcement of existing pile foundation bearing capacity disclosed in this example are: 60 parts of sintering red mud, 35 parts of casting pig iron slag, 20 parts of limestone tailings, and desulfurized gypsum 18 parts, 25 parts of activator, 22 parts of admixture. Activator components and mass ratios are 20 parts of potassium hydroxide aqueous solution with a concentration of 12%, 18 parts of carbide slag and 12 parts of quicklime. The admixture components and mass ratio are 3 parts of 7Ⅱ type quick-setting agent, 10 parts of calcium sulfoaluminate expansion agent, 7 parts of calcium sulfate, 3 parts of carboxymethyl cellulose, and 6 parts of melamine-based water reducer.

[0045] The preparation method corresponding to this example: stir red mud, blast furnace slag, limestone tailings and desulfurized gypsum in a dry state for 120s in a dry state, add corresponding proportion o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com