Up ramp dismantling system and construction method

A construction method and system technology, applied in separation methods, chemical instruments and methods, use of liquid separation agents, etc., can solve problems such as affecting the demolition efficiency of upward ramps, prone to potential safety hazards, and accumulation of water in construction sites, and achieve dust reduction on construction sites. , The effect of saving manpower and time, and reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

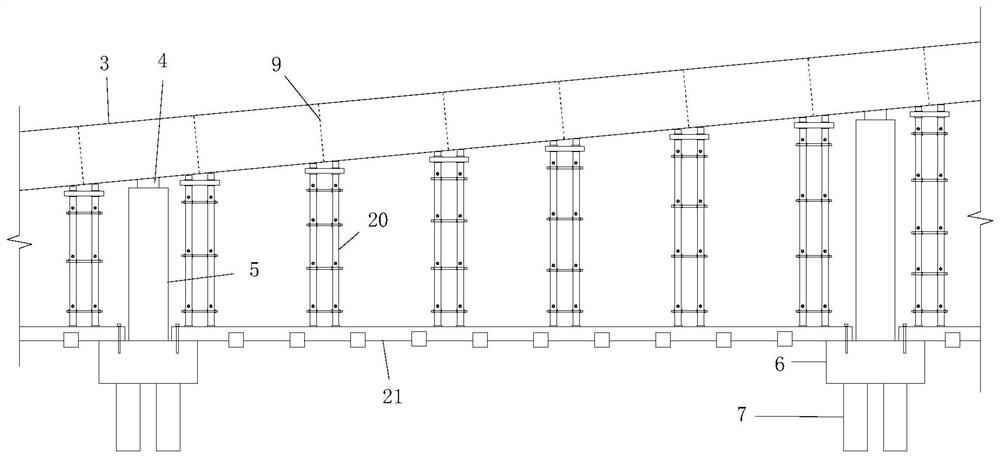

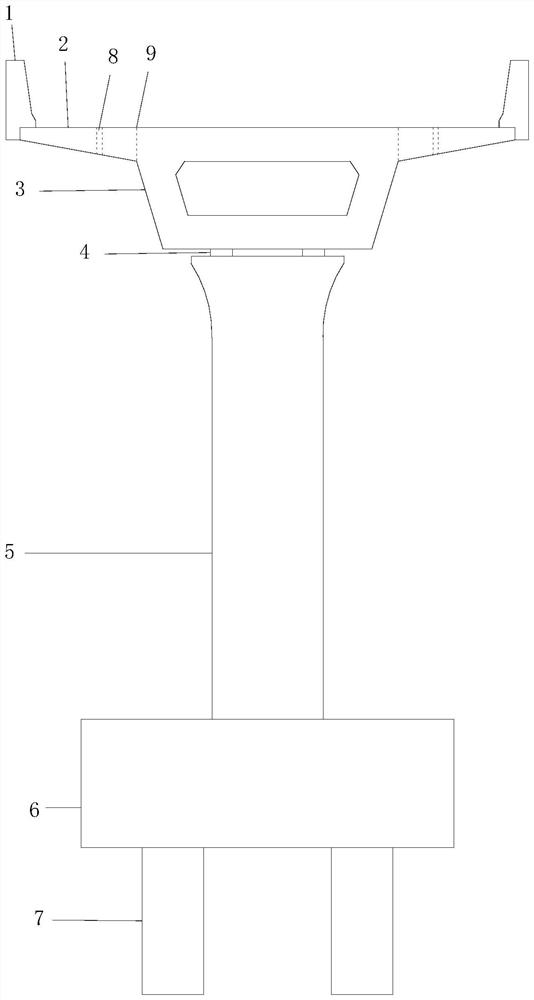

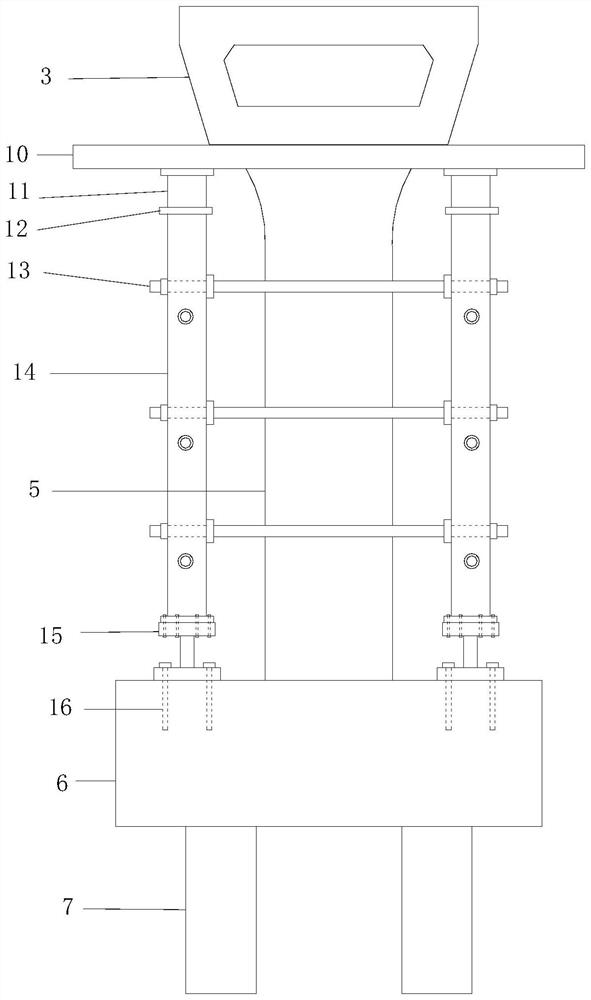

[0047] Such as Figure 1-9 As shown, the up-ramp demolition system includes the temporary buttress system erected at the bottom of the box girder 3 of the up-ramp, and the construction enclosure 26 spraying system located on the periphery of the construction area, wherein the up-ramp needs to be dismantled during the demolition process. Pavement layer, remove the guardrails and flange plates 2 on both sides, and then remove the box body of the continuous box girder 3 and the pier column 5, the support 4 between the pier column 5 and the continuous box girder 3, etc.

[0048] The temporary pier system includes a steel pipe support 20 and a support foundation 21, wherein the steel pipe support 20 includes a main beam 11, a distribution beam 10 located at the top of the main beam 11, a steel pipe column 14 located at the bottom of the main beam 11 and two The high-strength tension bolts 13 between the steel pipe columns 14 are used to fix two adjacent steel pipe columns 14 throug...

Embodiment 2

[0055] The construction method of the up-ramp demolition system uses the above-mentioned up-ramp dismantling system to dismantle the up-ramp, specifically including the following steps:

[0056] S000, construction enclosure 26 sprinkler system installation:

[0057] S001. Transport the fence column 25 and fence 26 manufactured in advance in the factory to the construction area for assembly to form the construction fence 26. Both the fence 26 and the movable fence 31 are made of steel plates at the bottom and steel wire mesh at the top manufactured;

[0058] S002. According to the construction requirements, a temporary opening 29 is set on the construction fence 26. After the position of the temporary opening 29 is selected, the door frame 30 is welded on the inner side of the top of the fence column 25 on both sides of the position, and the bottom of the door frame 30 is fixed with an anchor bolt 16 On the ground, weld the rail clamp 34 on the downward surface of the door fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com