Wood structure anti-shearing connecting element, connecting structure, box body platform structure and construction method

A technology for shear-resistant connectors and wood structures, applied in building components, building structures, floor slabs, etc., can solve the problems of difficulty in realizing secondary beam shear-resistant connections, poor shear force transmission effect, and long force transmission paths. The size of the node area, the effect of improving the ability to transmit shear force, and improving the reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

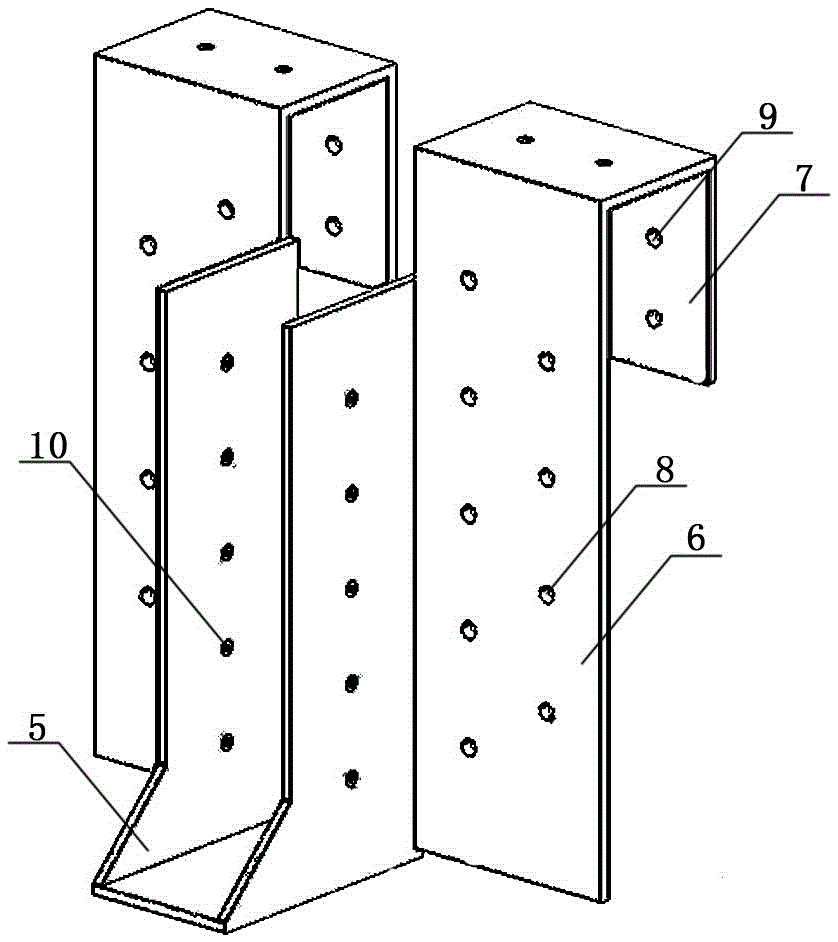

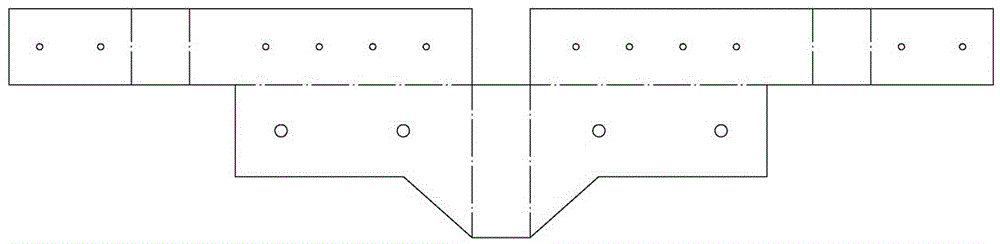

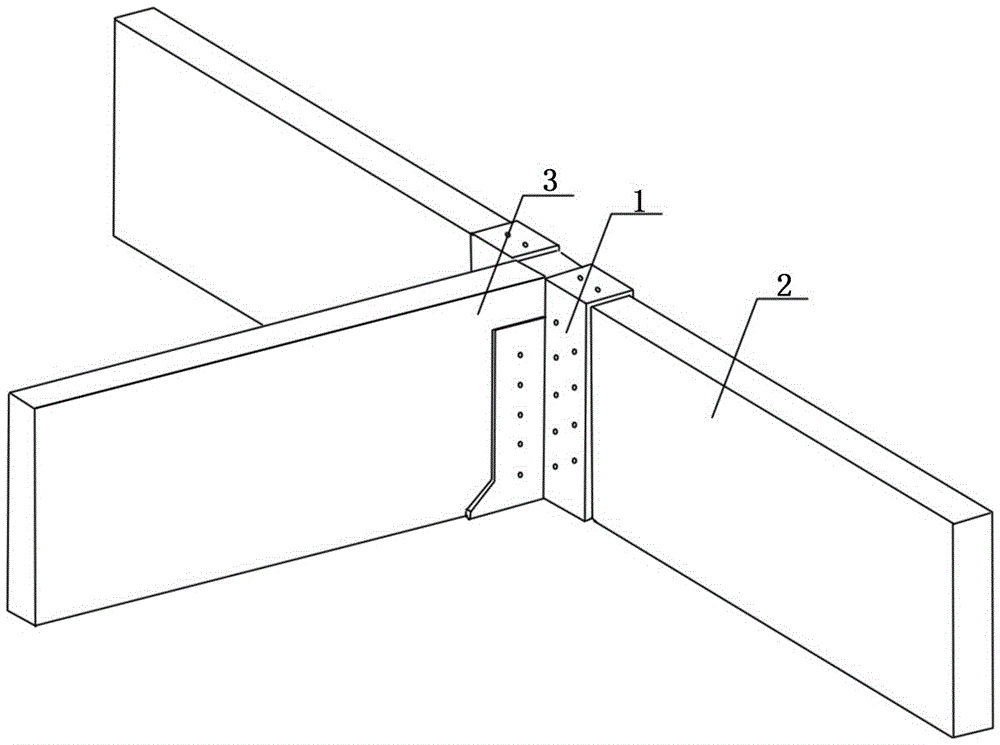

[0053] Examples see figure 1 As shown, the shear connectors of this timber structure, see figure 2 As mentioned above, the connector 1 is an overall structure formed by vertically bending a 3mm thick steel plate sequentially. It can be made by cold working. The flange 6 extending symmetrically from both sides of the flange 6 and the hook head 7 bent from the upper end of the flange 6 back to the web, the web 5, the flange 6 and the hook head 7 are all provided with connection holes .

[0054] see figure 1 As shown, the web 5 is a U-shaped structure surrounded by a vertical section, a horizontal section, and a vertical section in turn. One side of the vertical section is vertical and extends outward at 90 degrees to form a flange. The upper part is vertical and the lower part is inclined, and the vertical section as a whole has a flat plate structure with a narrow top and a wide bottom; at least one row of secondary beam connection holes 10 arranged at even intervals is ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com