Underground diaphragm wall I-shaped steel joint water stop control structure and construction method thereof

A technology of I-beam and control structure, which is applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve the problems of low construction efficiency, labor-consuming and construction period, I-beam entrained glue, etc., so as to improve construction efficiency. , Waterproof quality assurance, good connection integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

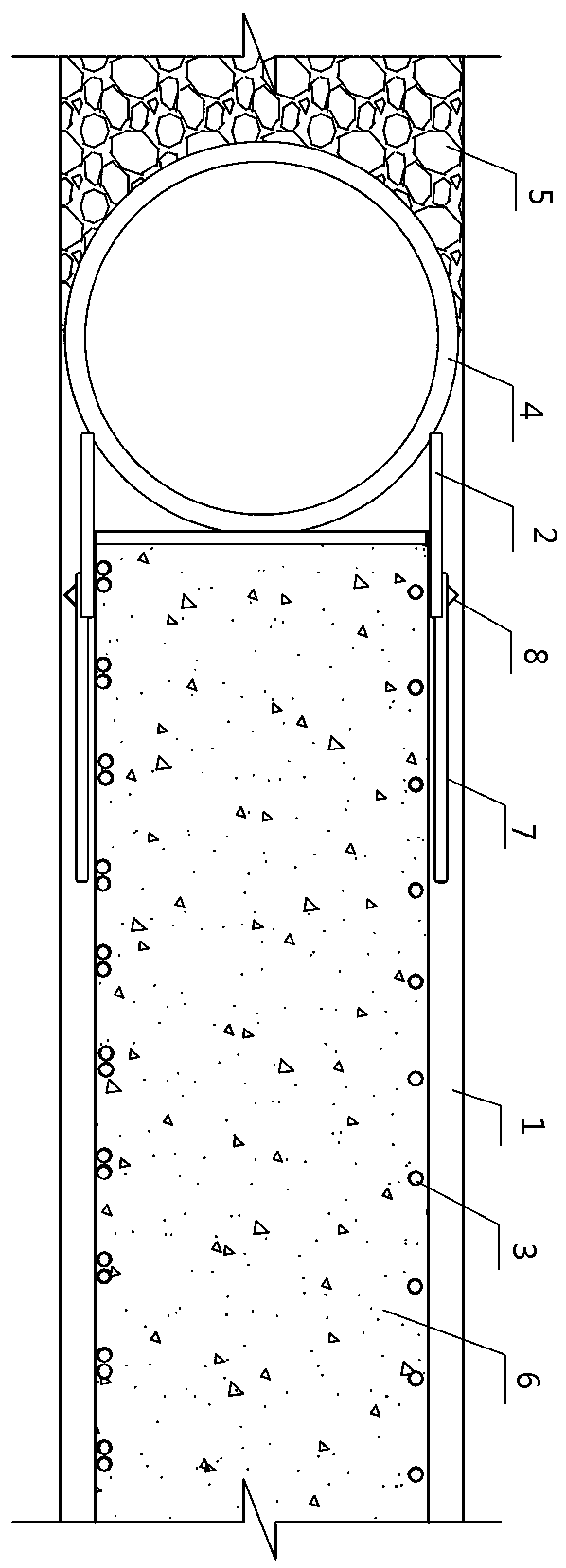

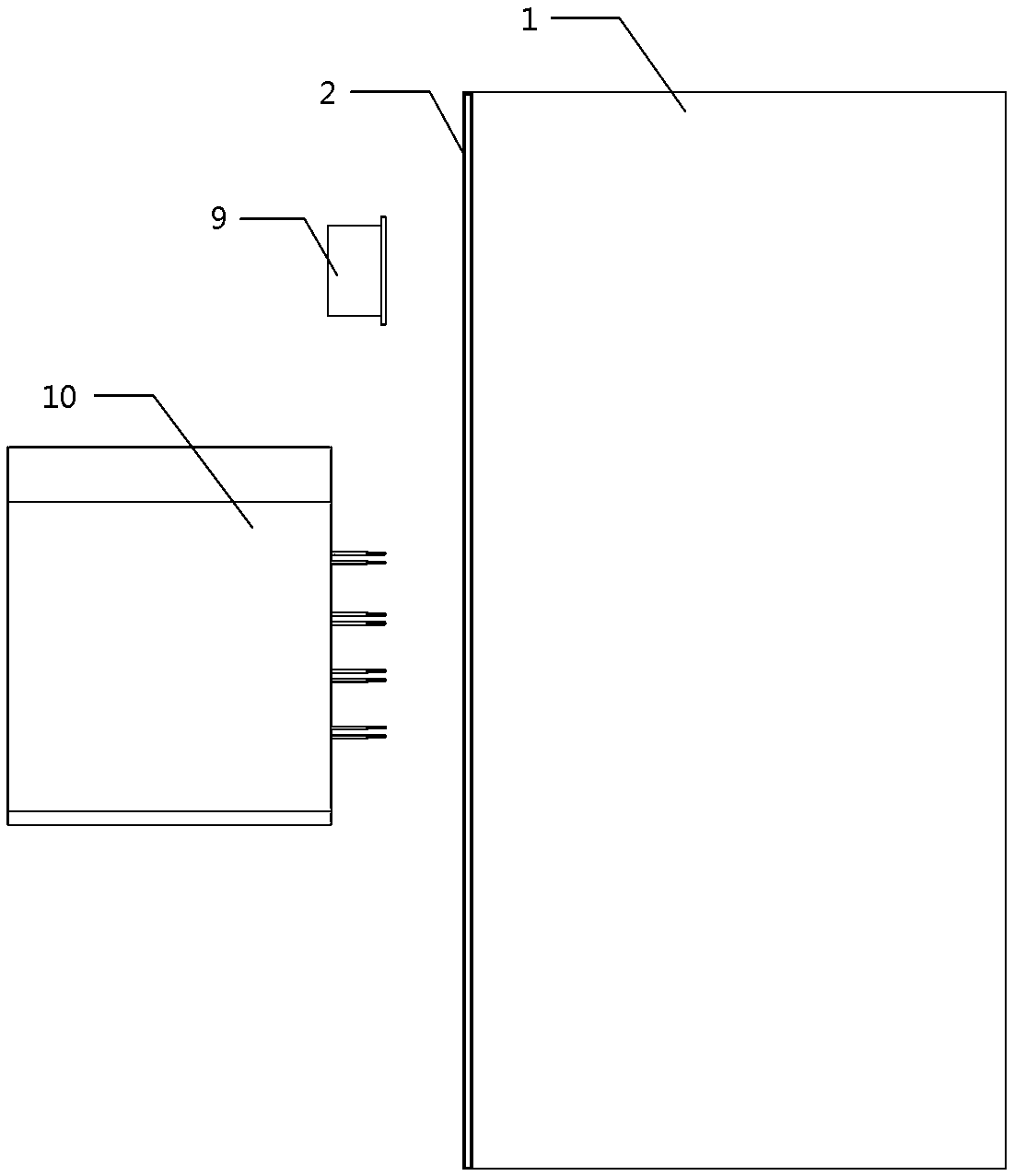

[0031] A ground connection wall H-shaped steel joint water-stop control structure and its construction method, for examples see figure 1 As shown, a ground connection wall I-shaped steel joint water-stop control structure includes an underground continuous wall groove section 1, an I-shaped steel joint 2 with a cross section facing upwards and vertically arranged in the underground continuous wall groove section 1, welded on The reinforcement cage 3 on one side of the web of the I-shaped steel joint 2, the concrete 6 poured on the reinforcement cage 3 and in the underground continuous wall groove section 1, the cross-section faces upwards, and is vertically closely attached to the I-shaped steel joint 2 The lock pipe 4 on the other side of the web plate, and the counter-pressed gravel 5 filled in the other side of the lock pipe 4; a pair of anti-slip plates 7 are welded symmetrically on the outer side of the flange plate of the I-shaped steel joint 2, The grout-stop bead 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com