Novel structure of flood control dam on silty-fine sand stratum

A new type of structure, silty sand technology, applied in infrastructure engineering, dams, barrages, etc., can solve the problems of insignificant flood control benefits, reduce construction difficulty, solve insufficient bearing capacity, and increase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

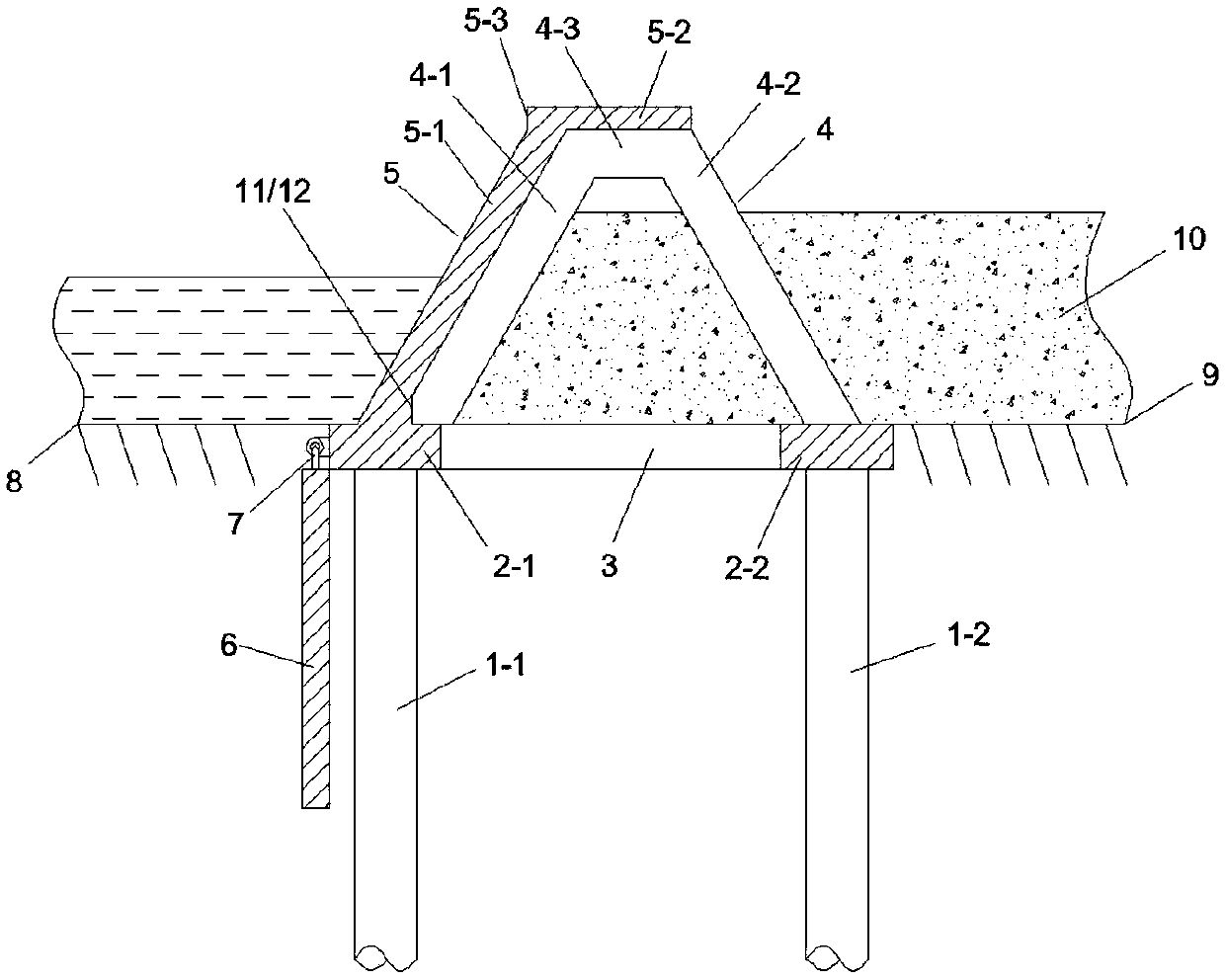

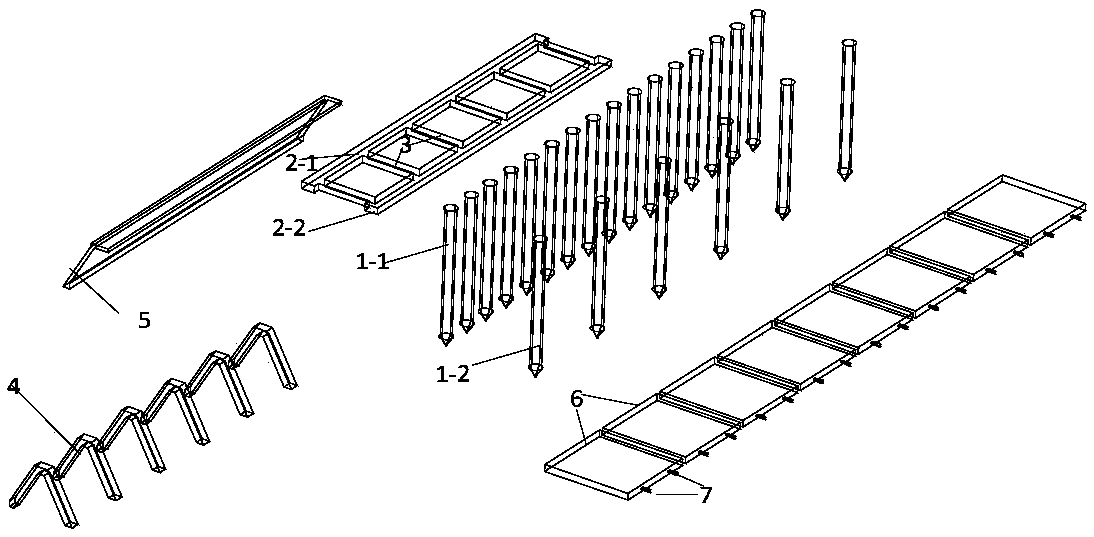

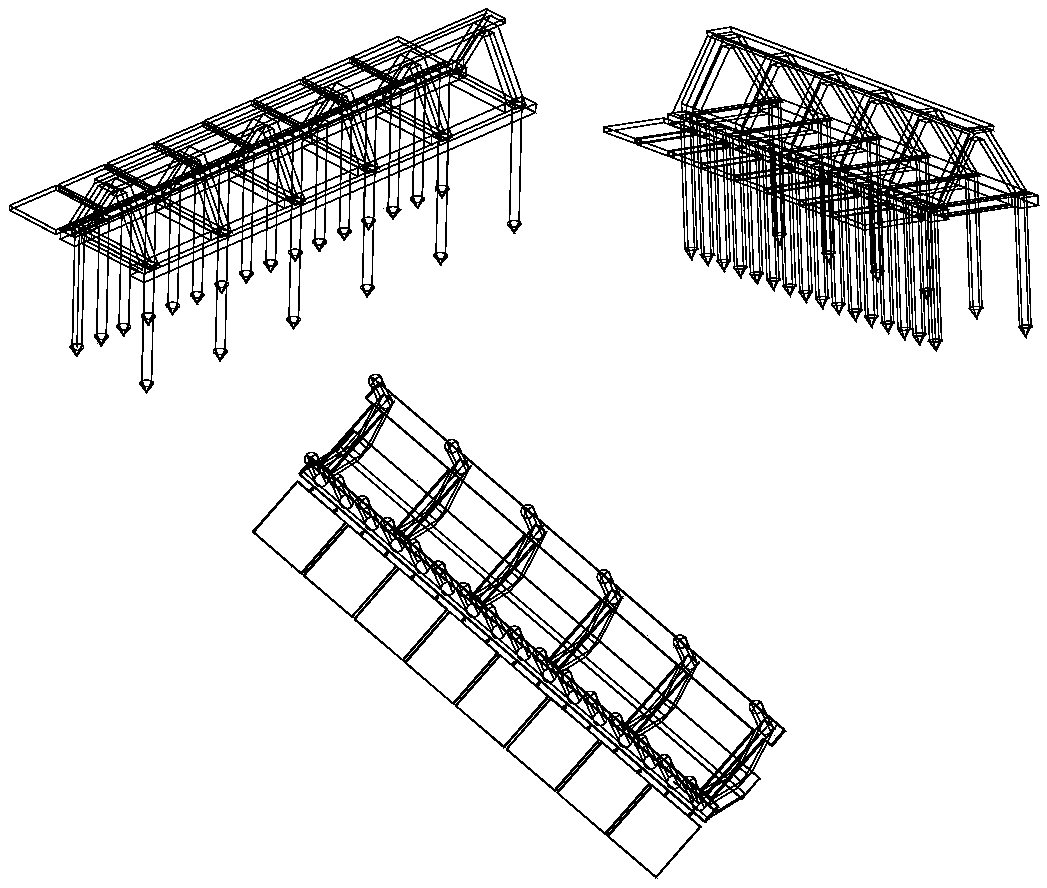

[0039] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown is a specific embodiment of a novel structure of a silty sand formation flood control dam according to the present invention. In this embodiment, a straight line along the dam is adopted, the crest of the dam is allowed to overcome waves, and the angle between the dam body and the water flow is 0°. The specific structure Including: two rows of pile sinking 1-1 and 1-2 driven into the ground, the arrangement density of the inner row of pile sinking 1-1 near the river is greater than that of the outer row of pile sinking 1-2, the arrangement density of the pile sinking 1-1 , 1-2 During manufacture, use a cylindrical mold with a steel cage inside to pour concrete. During pouring, use a concrete vibrator to vibrate the concrete evenly. After demoulding, maintain it and sink the pile 1-1 , 1-2 surface anti-corrosion treatment, such as coating cold base oil. In this embodiment, pile sinking 1-1 and 1-2 adopt holl...

Embodiment 2

[0056] Such as Figure 5 and Figure 6 Shown is another kind of specific embodiment of the novel structure of a kind of silty sand formation flood control dam of the present invention, in the present embodiment the structure of the silt fine sand layer river section flood control dam is basically the same as the structure in embodiment 1, the same No more details here, the difference is that this embodiment also includes: arch beams 13, the arch beams 13 are prefabricated in the slope retaining wall 5-1, and are distributed continuously, the arch beams 13 are arched towards the direction of the river, Two adjacent arch beams 13 are connected by a connecting plate 14, and the position of the connecting plate 14 is set corresponding to the supporting beam 4-1. Since the slope retaining wall 5-1 has a certain height, multiple arch beams 13 can be arranged in the slope retaining wall 5-1.

[0057] This enables the slope retaining wall 5-1 between the two supporting beams 4-1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com