Grouting pipeline device, conical special-shaped pile and application method thereof

A technology of grouting pipes and special-shaped piles, which is applied in sheet pile walls, buildings, infrastructure projects, etc., can solve problems such as the reduction of lateral friction resistance, and achieve the effects of reducing difficulty, flexibility and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

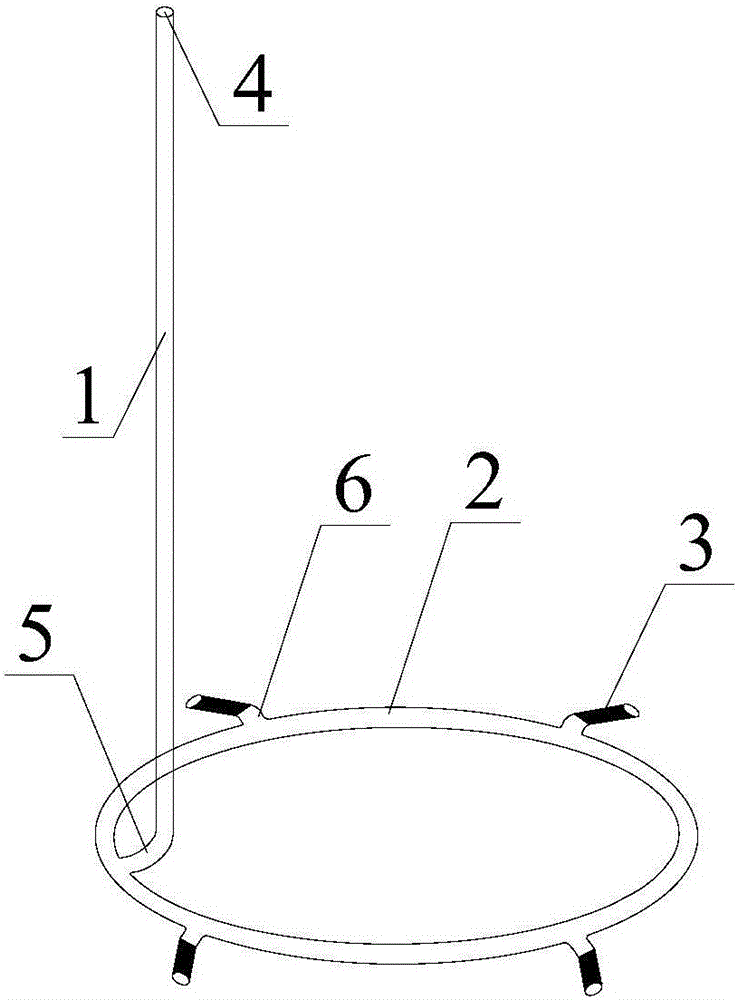

[0027] Such as figure 1 As shown, a set of grouting pipeline device includes a longitudinal grouting pipe 1, an annular pipe 2 and a grouting device 3, the longitudinal grouting pipe 1 and the annular pipe 2 communicate through a first arc-shaped conduit 5, and the annular pipe 2 and the grouting pipe The device 3 is connected through a second curved conduit 6.

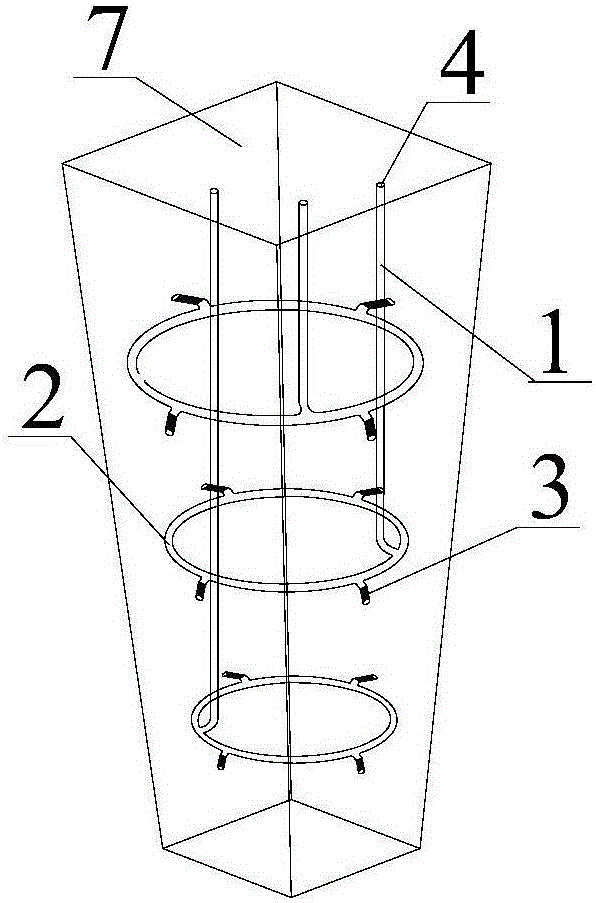

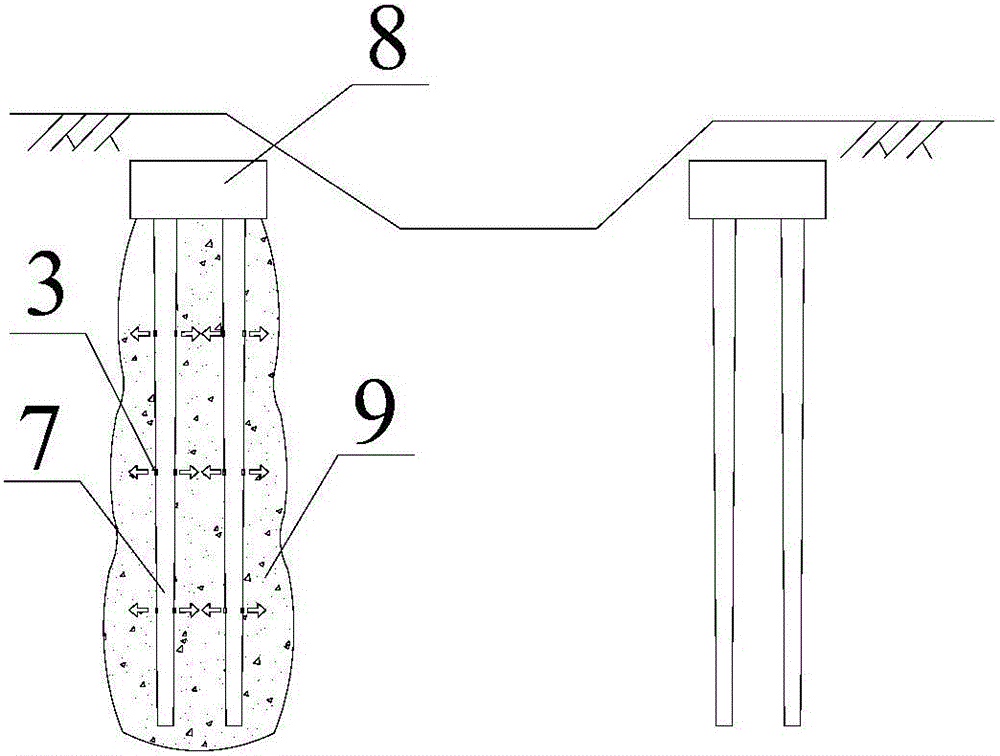

[0028] figure 2 It is a structural schematic diagram of an embodiment of a tapered special-shaped pile in the present invention. In general, the grouting section can be arranged according to the distribution of the soil layer on the side of the pile and the properties of the soil. The first grouting section should be 5m below the pile top, and the distance between adjacent grouting sections should be 5-9m. In this embodiment, considering the geological conditions within the scope o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com