Reinforcing device for reinforcing steel member in communication tower

A reinforcement device and steel component technology, which is applied in the direction of towers, building construction, building maintenance, etc., can solve the problems of insufficient bearing capacity of steel components, and achieve the effect of convenient installation and increased bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

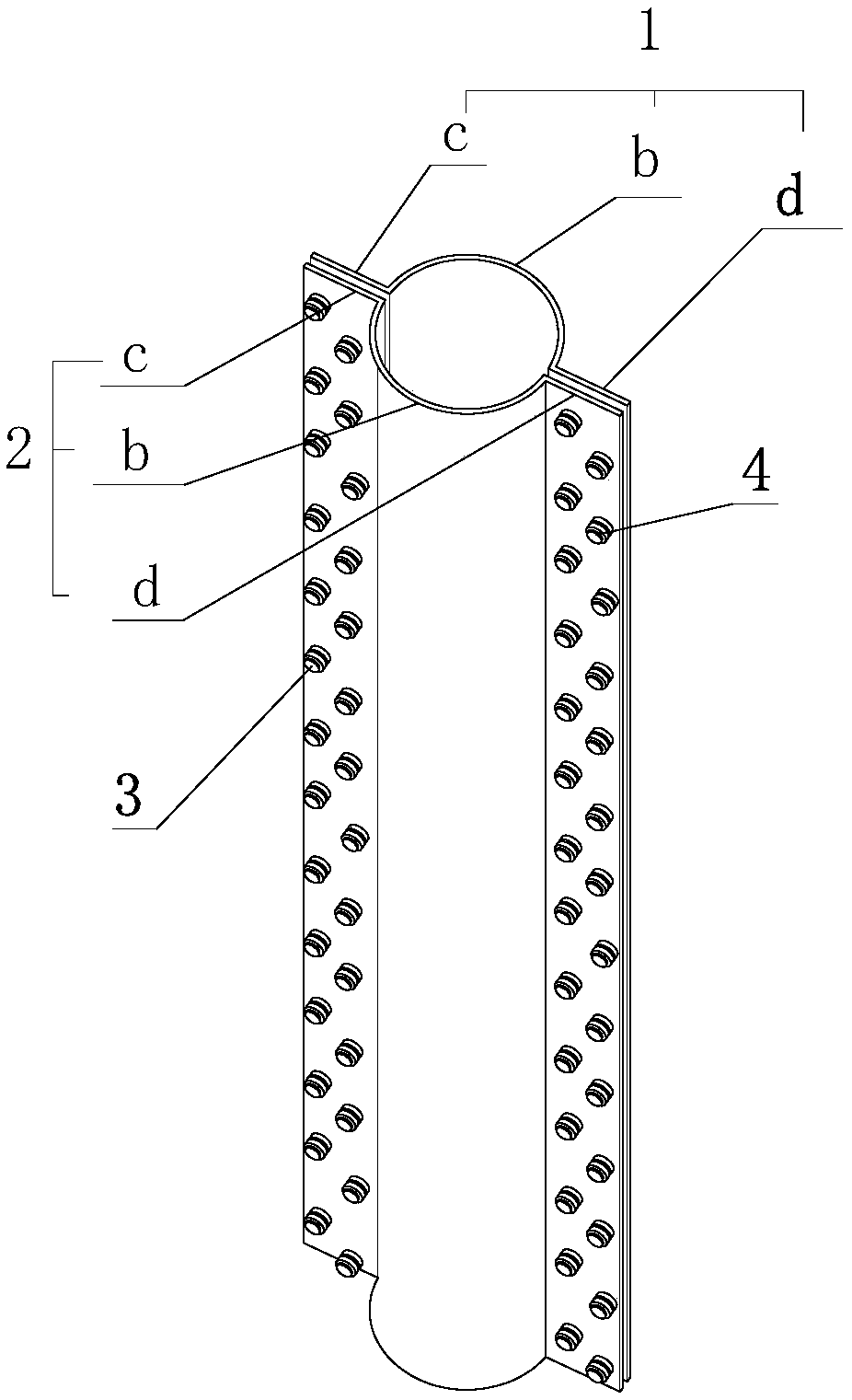

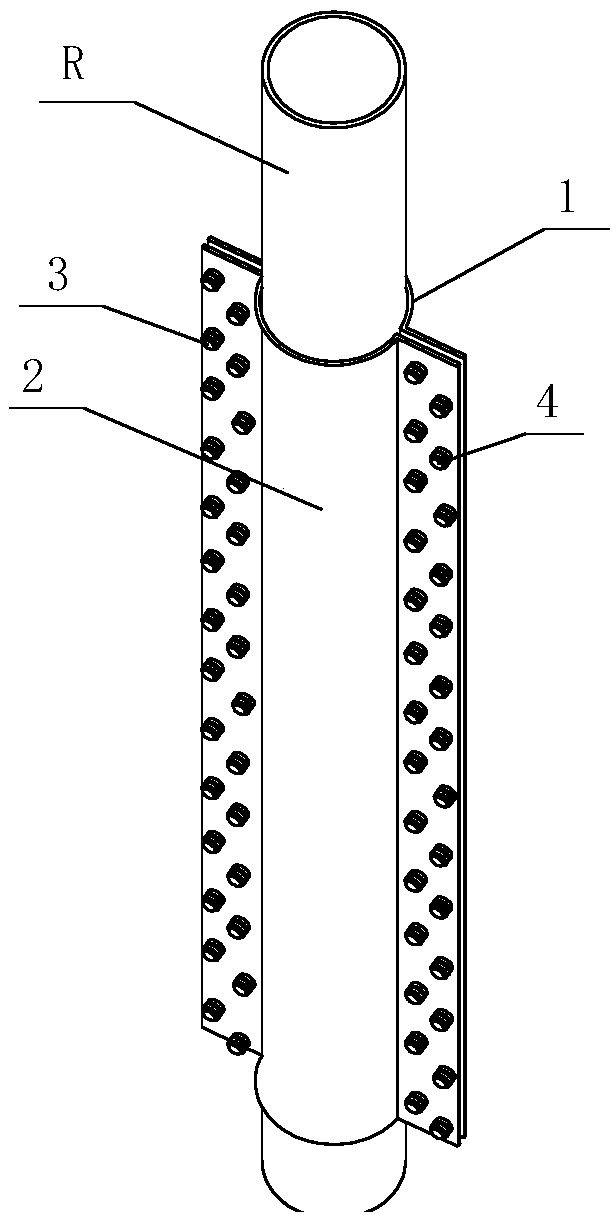

[0030] refer to image 3 , when the steel member R to be reinforced is a columnar structure, the cladding part b is a curved plate, and the first connecting part c and the second connecting part d are planar plates arranged on both sides of the axis of the curved plate , during reinforcement, the first reinforcing body 1 and the second reinforcing body 2 are arranged oppositely on both sides of the columnar steel member R, and the cladding parts b of the two are respectively attached to the outer wall of the steel member R; then Use the first connecting piece 3 to connect the first connecting part c of the first reinforcing body 1 and the first connecting part c of the second reinforcing body 2 together, and use the second connecting piece 4 to connect the second connecting part c of the first reinforcing body 1 part d and the second connecting part d of the second reinforcing body 2 are connected together, and the covering part b of the first reinforcing body 1 and the coveri...

Embodiment 2

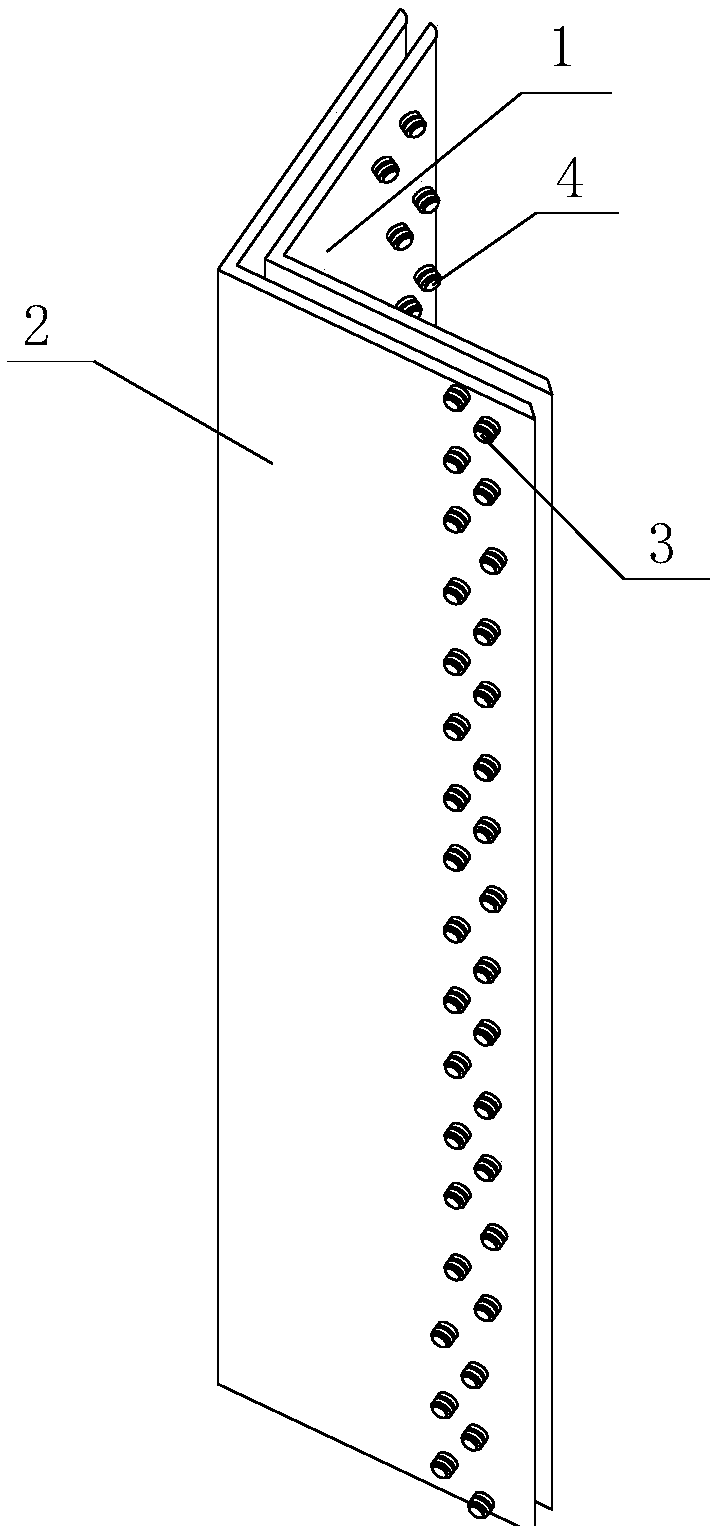

[0032] refer to Figure 4 , when the steel member R to be reinforced is an angle steel structure, the cladding part b is an angle steel, the first connecting part c is located in the same plane as one side of the angle steel, and the second connecting part d is located in the same plane as the other side of the angle steel in plane. When strengthening, the first reinforcing body 1 and the second reinforcing body 2 are arranged on the inside and outside of the angle steel-shaped steel member R, and the cladding parts b of the two are respectively attached to the outer wall of the steel member R; then use The first connection part 3 connects the first connection part c of the first reinforcement body 1 and the first connection part c of the second reinforcement body 2 together, and the second connection part c of the first reinforcement body 1 is connected by the second connection part 4 d and the second connecting part d of the second reinforcing body 2 are connected together,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com