Cast-in-place X-shaped large-diameter hollow concrete pile and construction method thereof

A technology of hollow concrete and large diameter, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as uneven wall thickness, difficulty in concrete pouring, and the effect of pile side friction has not been considered, so as to reduce the construction cost , facilitate quality control, improve the effect of strength utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The protection scope of the present invention is not limited only to the description of this embodiment.

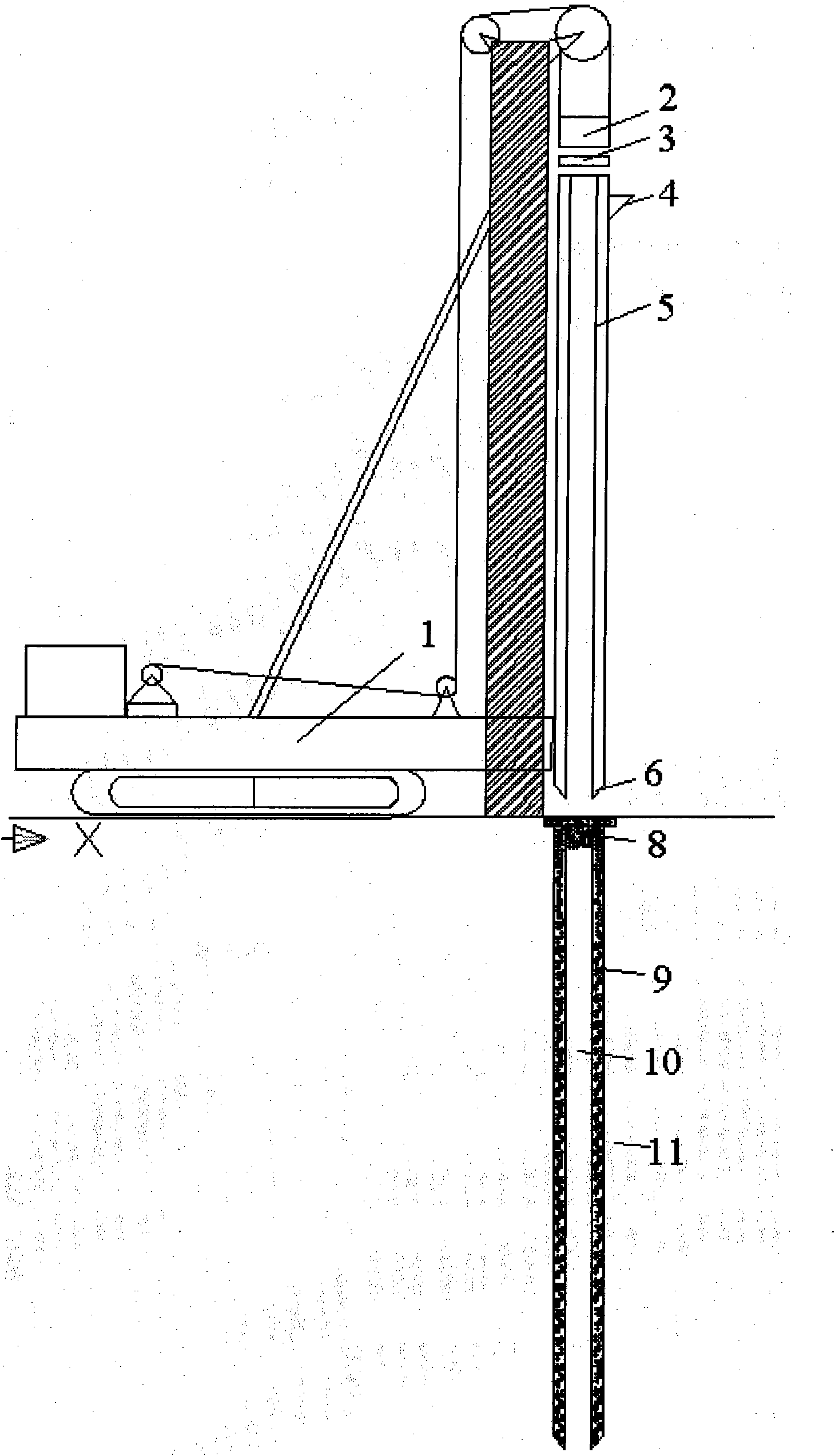

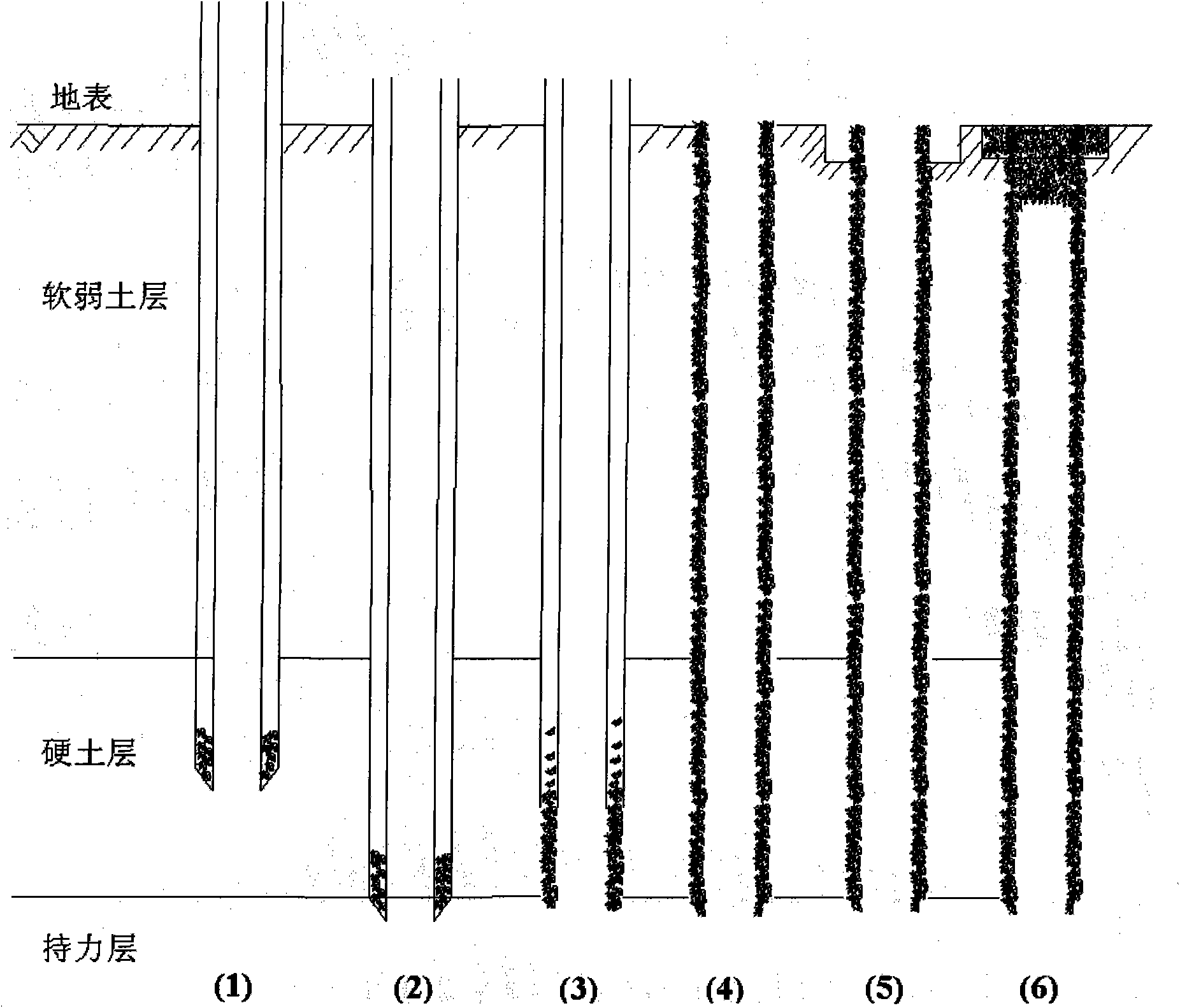

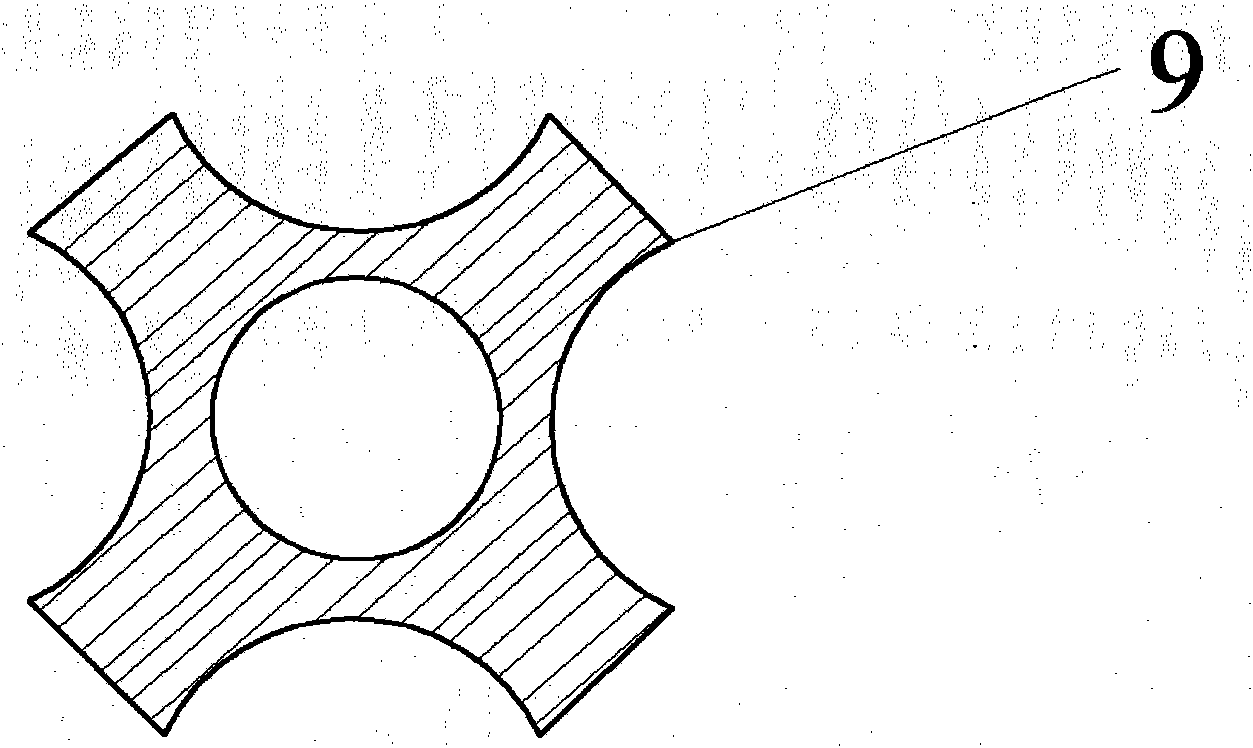

[0030] Such as figure 1 with figure 2 As shown, the vibratory head 2 is provided on the upper part of the vibratory pile driver 1, the vibratory head 2 is riveted with flanges 3 screws and the pile mold sinking tube 5 with scale, the sinking tube 5 has the rigidity and strength meeting the requirements of vibratory piling, and the outer wall is X The middle of the circular circular steel plate on the inner wall is a cavity, and the lower part of the immersed tube 5 is connected with the valve spud shoe 6; Immersed tube 5 bottom also can connect prefabricated pile point 7, as Figure 4 As shown, the upper part of the prefabricated pile point 7 is a connecting head 13, and the lower part is a cutting knife 12.

[0031] When implemented, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com