Device for knobby pushing and expanding spiral immersed tube stake and its engineering method

A technology of immersed tubular piles and spirals, applied in sheet pile walls, foundation structure engineering, drilling equipment and methods, etc., can solve problems such as failure to release internal stress, increase vibration and noise, increase bearing capacity, etc., and achieve construction The effect of cost reduction, increase of construction speed and increase of pile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

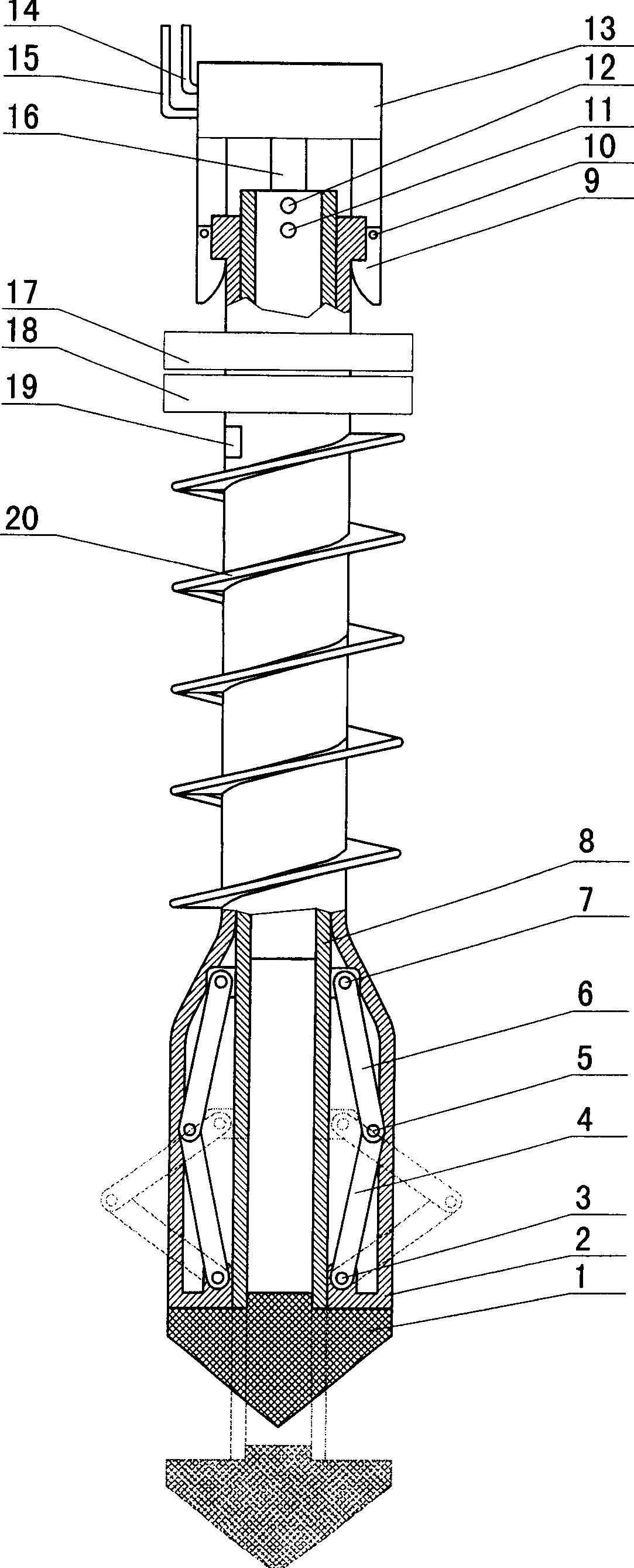

[0010] Such as figure 1 As shown: the lower end of the outer tube 2 is connected to the cement head 1, the outer tube 2 is connected to the lower bow pressing arm 4 through the pivot pin 3, the lower bow pressing arm 4 is connected to the upper bow pressing arm 6 through the pivot pin 5, and the upper bow pressing arm 6 is connected to the pivot pin 7 Connect the inner pipe 8, the outer pipe 2 is socketed with the inner pipe 8, the outer pipe is welded with a spiral blade 20, the upper part of the outer pipe 2 is opened with a sprue 19, the upper part of the outer pipe 19 is connected with a hydraulic motor 18, and the outer pipe 2 The vibrator 17 is connected above the hydraulic motor 18 of the vibrator 17, and the outside of the outer tube above the vibrator 17 is a locking block 9, which is connected with the outer tube 2 through the pivot pin 10, and the piston rod 16 is connected with the inner tube 8 through the pivot pins 11, 12, and the piston Rod 16 is placed in oil c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com