Template system used for overall pouring of large-area tunnel immersed tube

An integral pouring, large-volume technology, used in construction, artificial islands, infrastructure engineering, etc., can solve the problems of difficult to guarantee the quality of pouring products, no automatic production, and high production costs, avoiding waste of resources and saving production costs. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

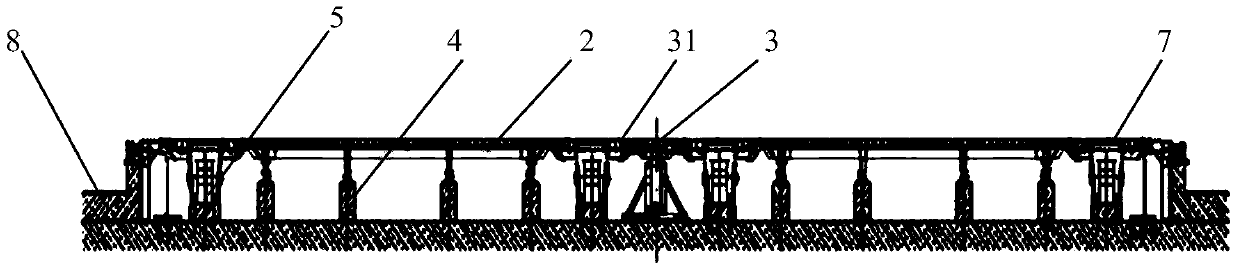

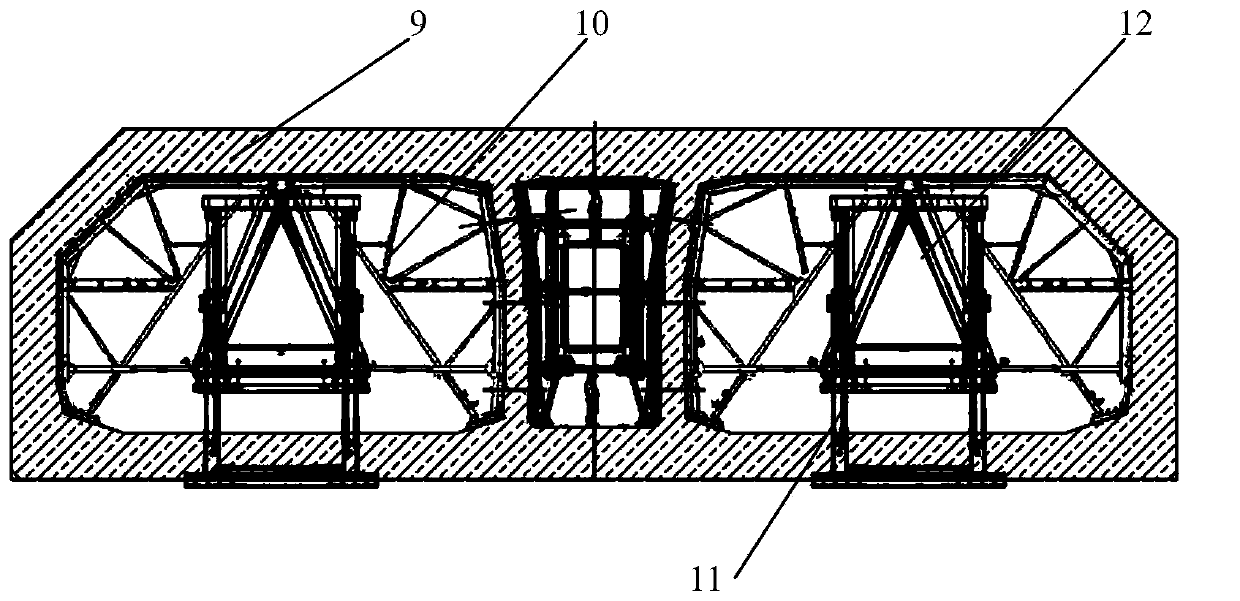

[0027] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] This embodiment provides a formwork system for integral pouring of large-volume tunnel immersed tubes in the field of tunnel construction, which includes a bottom form, a side form, an inner form, an end form and a hydraulic drive system, and the hydraulic drive system drives the bottom form respectively , side mold, inner mold move demoulding and reset. The formwork system is driven by a hydraulic system, and enables fast and accurate positioning of each module, which not only can be reused, saves production costs, but also improves work efficiency.

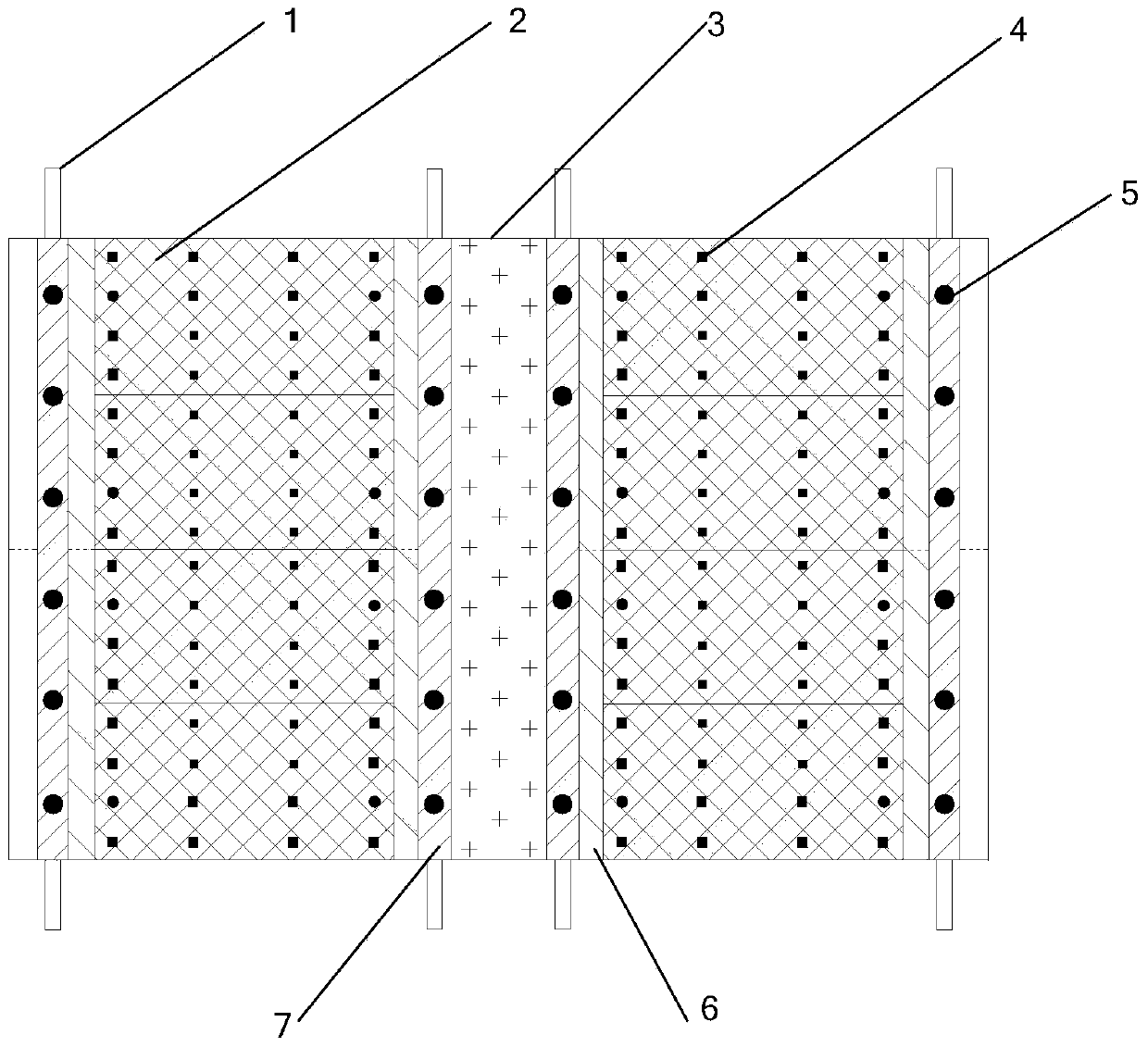

[0029] like figure 1 and figure 2 As shown, in the present embodiment, the bottom form includes a driveway bottom form 2 and a corridor bottom form 3, and the two sides of the driveway bottom form are respectively provided with a driveway folding bottom plate 6, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com