Immersed tube tunnel deformation monitoring and stress analyzing system and application method and functions of immersed tube tunnel deformation monitoring and stress analyzing system

An immersed tube tunnel and deformation monitoring technology, which is applied in the measurement, measurement device, surveying and mapping and navigation of the change force of the optical properties of the material when it is stressed, to achieve high reflectivity, accurate measurement results, and strong environmental adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

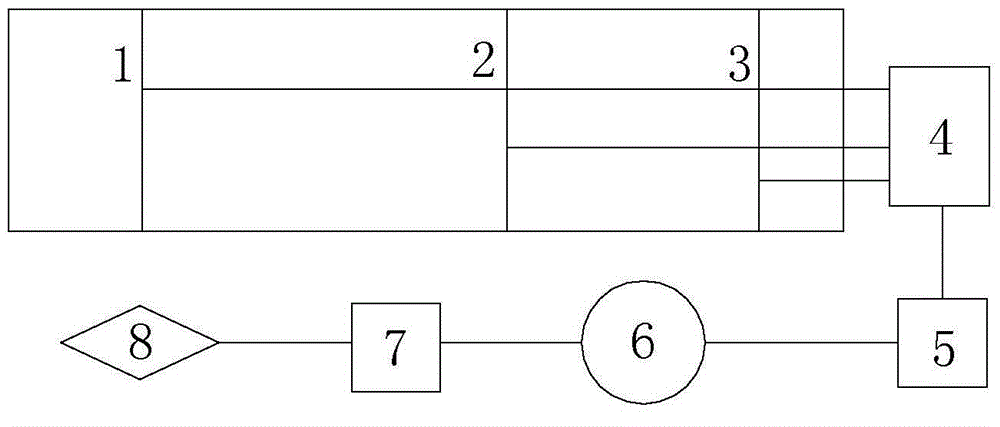

[0071] Example 1 Method of using an immersed tube tunnel deformation monitoring and force analysis system

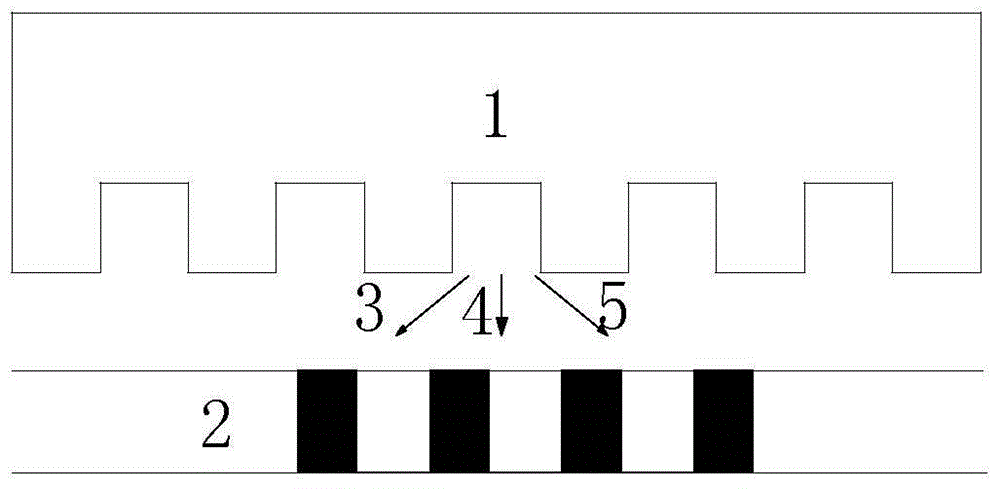

[0072] 1) Preparation of test element: The fiber grating is prepared by the phase mask method. During the preparation process, control the groove depth of the phase mask to 234±10nm and the duty ratio to 0.5, which can effectively suppress the zero-order diffraction of the diffraction spectrum While enhancing the diffraction efficiency of the ±1st order diffracted light, the zero order diffraction efficiency of the fiber grating made by the present invention can be as low as 2%, and the ±1st order diffraction efficiency can also reach 36%;

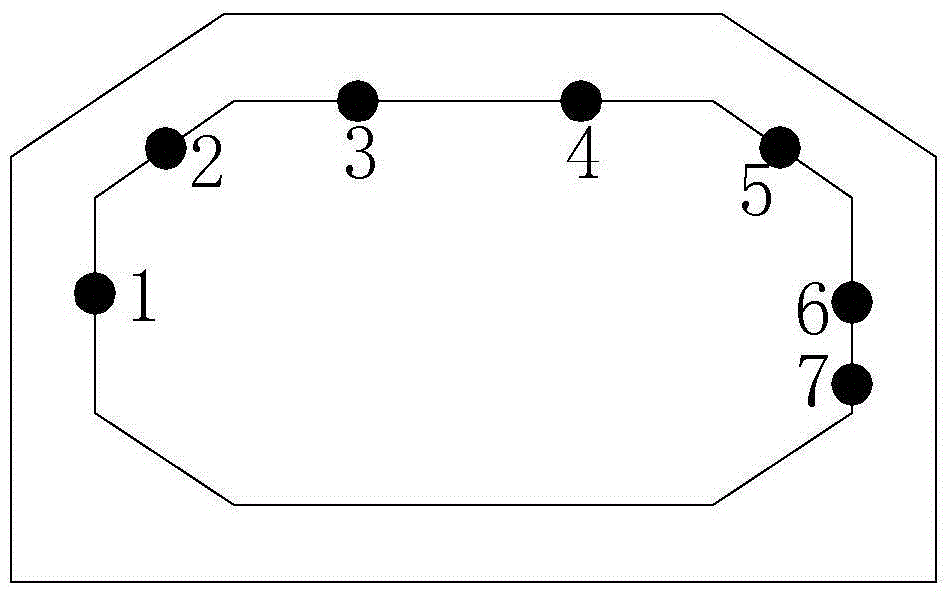

[0073] 2) Installation of test equipment: Several monitoring sections of the immersed tube tunnel are selected, each monitoring section is arranged with 6 monitoring points, each monitoring point is fixed with a fiber grating strain sensor, and each section is fixed with a fiber grating temperature sensor. It is a multi-section and multi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com