Crushed rock pile used for strengthening extremely soft soil foundation and construction method thereof

A soft soil foundation and construction method technology, applied in soil protection, infrastructure engineering, construction and other directions, can solve the problems of low cost of crushed stone piles, poor uniformity of crushed stone piles, and increased cost of foundation reinforcement treatment projects. The effect of simple structure, control of project cost and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

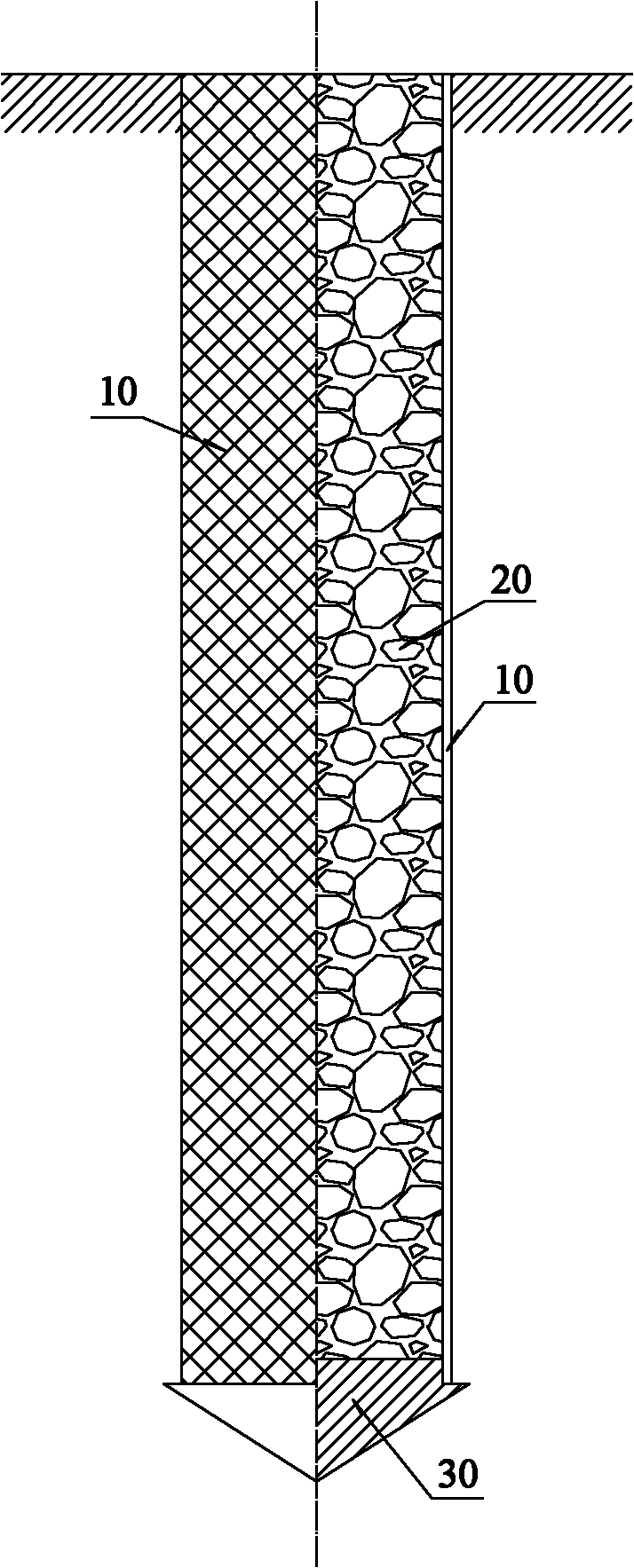

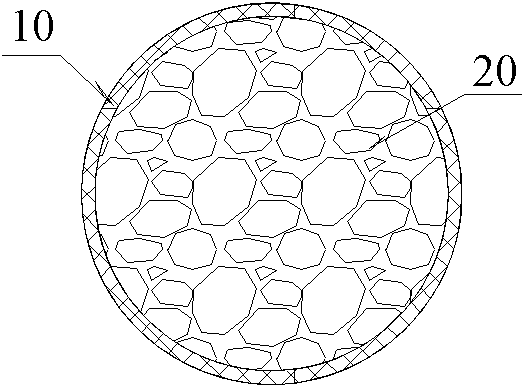

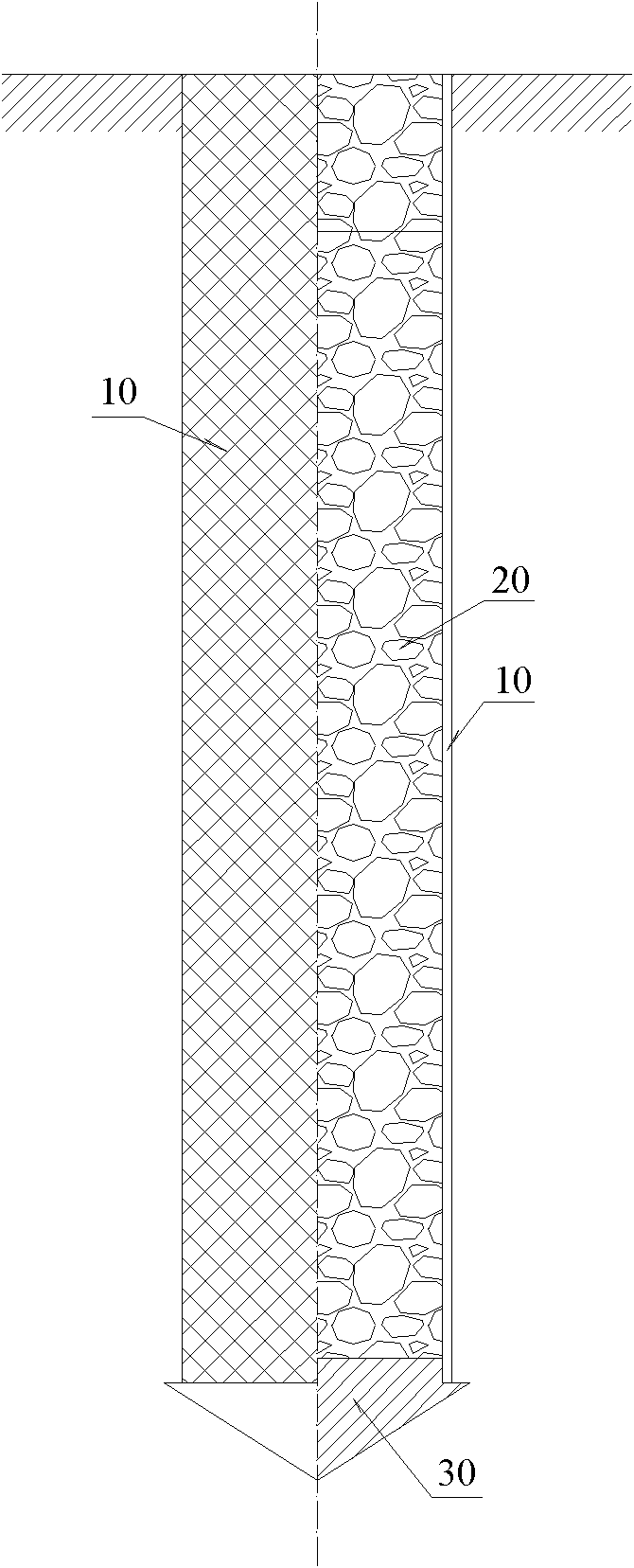

[0013] refer to figure 1 and figure 2 , the present invention is used for the gravel pile of very soft soil foundation reinforcement, comprises vertically extending to foundation bearing layer or design elevation net tube 10 and the crushed stone filler 20 that densely fills in it, and this net tube 10 peripheral wall has grid structure, its mesh size is 20 particle diameters smaller than that of crushed stone filler. The gravel filler 20 is constrained by the net cylinder 10 with a mesh structure. When the gravel pile passes through extremely soft soil layers such as silt and peat, it can effectively prevent the gravel filler 20 from diffusing to the outside of the pile diameter, so that the filling amount of the gravel filler is equal to The volume of the designed gravel piles is basically the same, and the advantages of low cost of the gravel pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com