Method for measuring flexural rigidity of immersed tube tunnel joint

A technology of immersed tunnel and bending stiffness, which is applied in the direction of applying stable tension/pressure to test the strength of materials, which can solve problems such as inconvenience in engineering design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

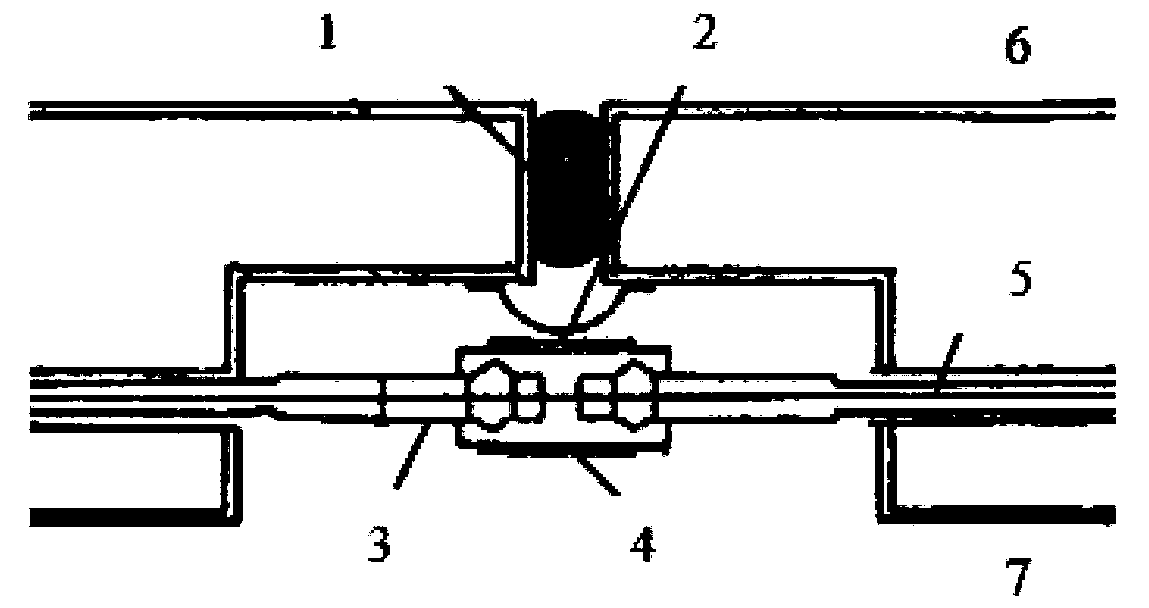

[0042] Such as figure 1 As shown in the structural diagram of the immersed tube tunnel joint, the inside of the immersed tube 7 is provided with a connecting steel cable 5, and the connecting steel cable 5 is sleeved in the sleeve 3, and the sleeves 3 of the two immersed tubes are connected by a connector 4, and the Set GINA waterstop 1 and Ω waterstop 2 at the gap where the two casings meet.

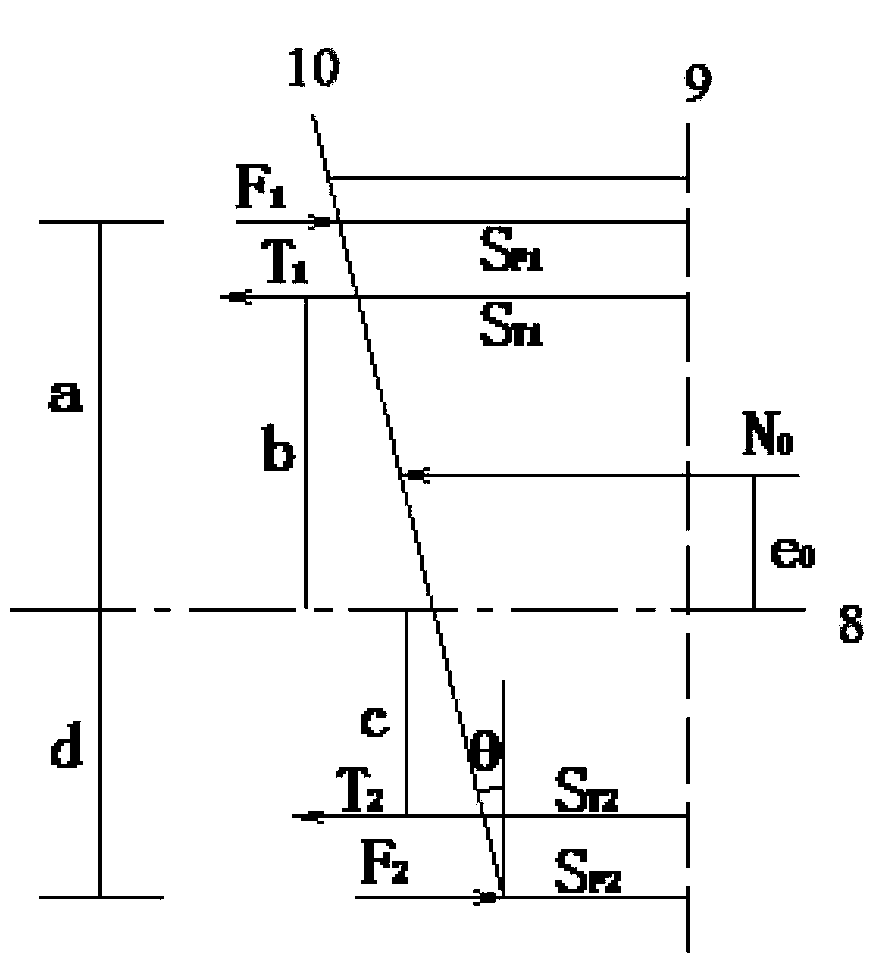

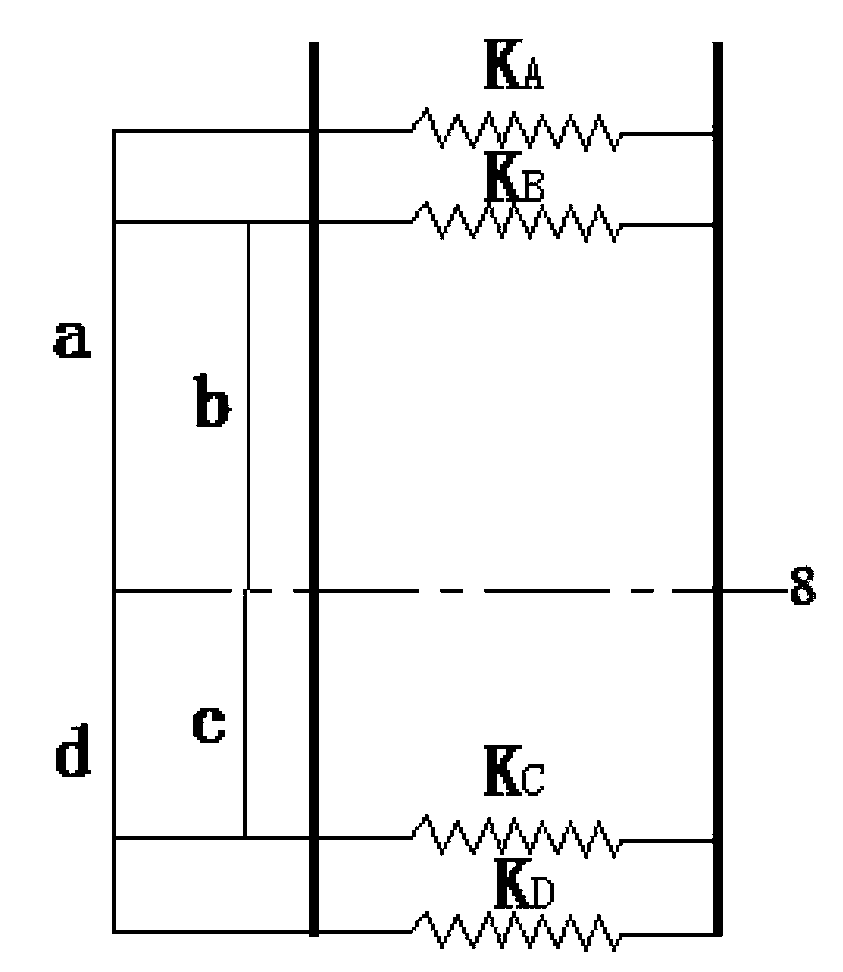

[0043] The present invention proposes reasonable simplifications according to the structural characteristics of the joints of the immersed tube tunnel, assuming that: (1) because the thickness and stiffness of the roof, floor and side wall at the joint position of the immersed tube tunnel joint are much greater than the GINA waterstop at the joint, the section of the joint can be It is assumed that it is a rigid plate without bending deformation; (2) the GINA waterstops arranged along the top and bottom plates of the joint section of the immersed tube tunnel are respectively simplified as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com