Cloth bag squeezing concrete branch pile and construction method

A technology of concrete and disc piles, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as side friction damage, insufficient bearing capacity, and unsatisfactory pile quality, so as to achieve good bearing performance and reduce pile Effects of settlement and enhanced shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In this embodiment, the pile-forming technical requirements, welding construction technical requirements, high-pressure grouting ratio, immersed tube technical requirements, etc. of cement mixing piles in this embodiment will not be described in detail, and the implementation of the construction of bag-expanded concrete support disc piles involved in the present invention will be focused on .

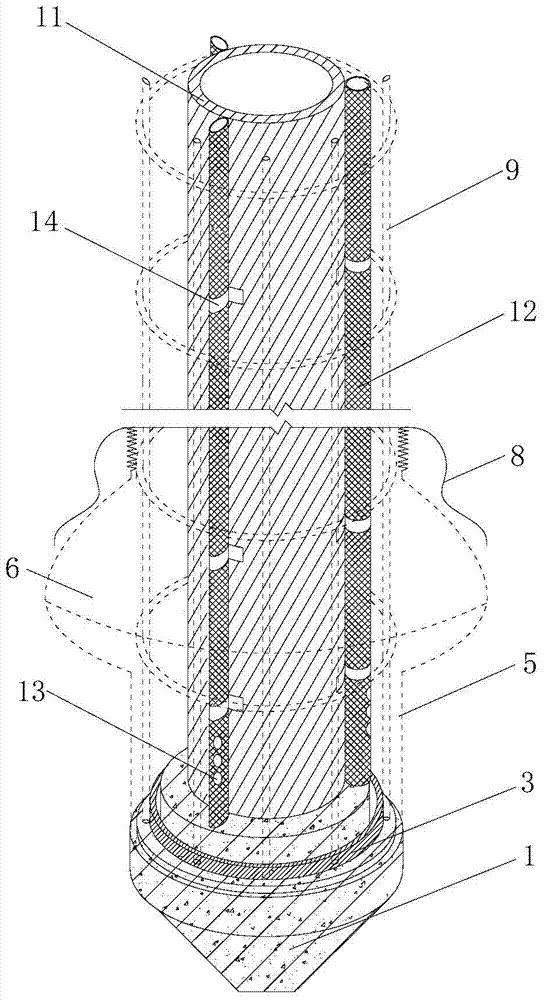

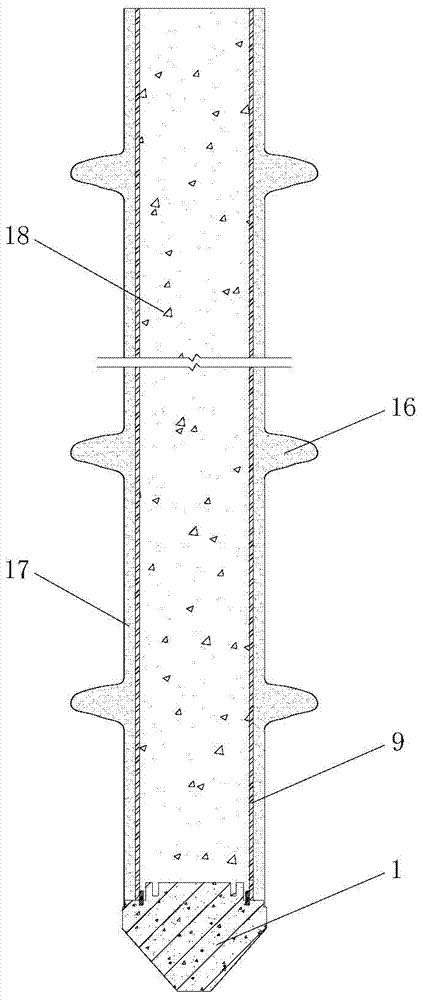

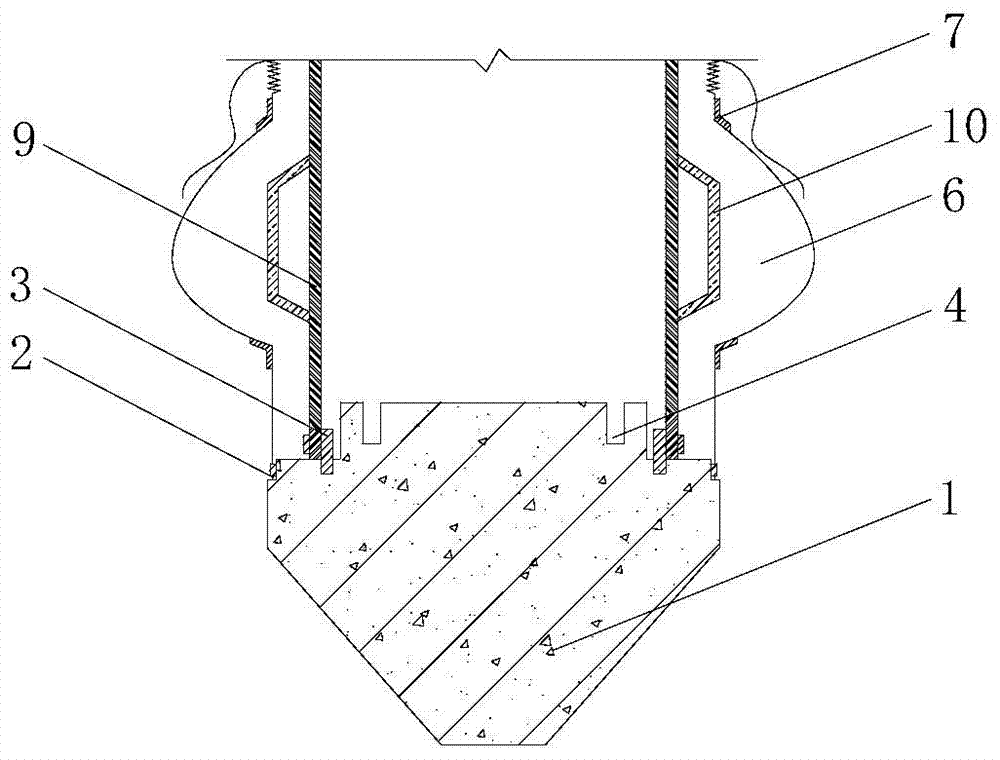

[0035] figure 1 Schematic diagram of the construction structure of the bag-expanded-extrusion concrete support disc pile of the present invention, figure 2 Sectional drawing of cloth bag expanded concrete support disc pile, image 3 It is a schematic diagram of the connection between the geotextile bag and the vertical main reinforcement of the reinforced body and the prefabricated pile tip.

[0036] refer to figure 2 The bag-extruded concrete abutment pile, the bottom of the abutment pile body is connected with a prefabricated pile tip, and the pile body is composed of a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com