Pile machine special for immersed tube pressure filling pile, using method thereof and application thereof

A technology of grouting piles and immersed pipes, which is applied to sheet pile walls, buildings, and foundation structure engineering, etc. It can solve the problems of small insertion length, low bearing capacity of pile ends, and easy deviation of steel cages, etc., to achieve good technology and guarantee The effect of verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

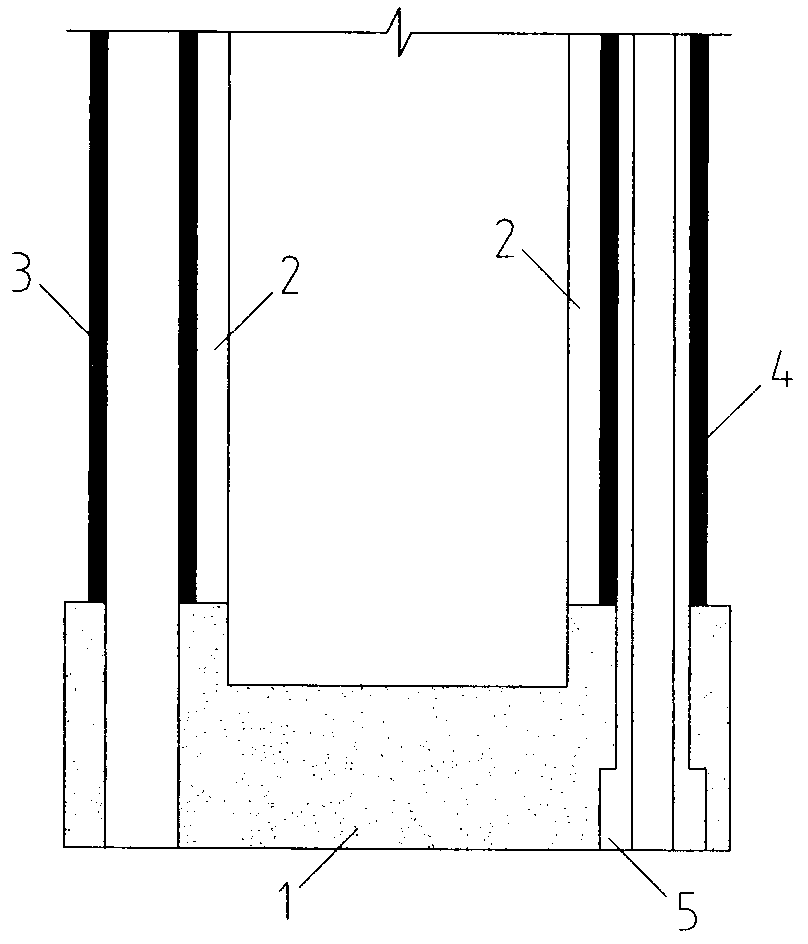

[0072] A construction project site, soil layer from top to bottom: 2m thick miscellaneous fill, 18m thick plastic state silty clay and slightly dense to medium dense state silty fine sand, fine sand interbedded, 3m thick fully weathered mudstone, 3m thick strong wind The weathered mudstone, the following is the moderately weathered mudstone.

[0073] The designed pile diameter is 600mm, the pile length is 27m, the bearing layer at the pile end is moderately weathered mudstone, and the ultimate bearing capacity of a single pile is 1500t, of which: the ultimate resistance at the pile end is 1100t, and the ultimate resistance at the pile side is 400t.

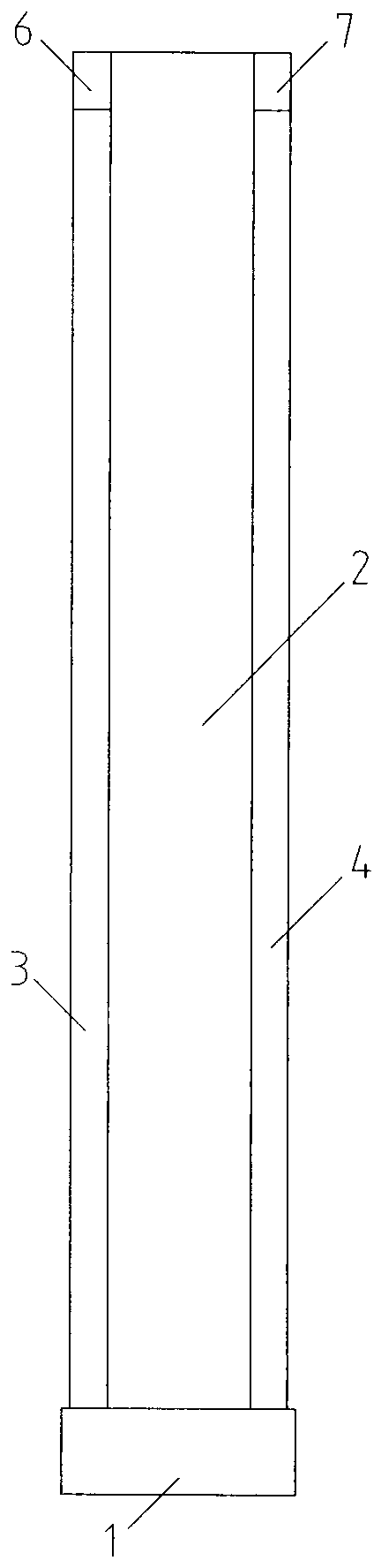

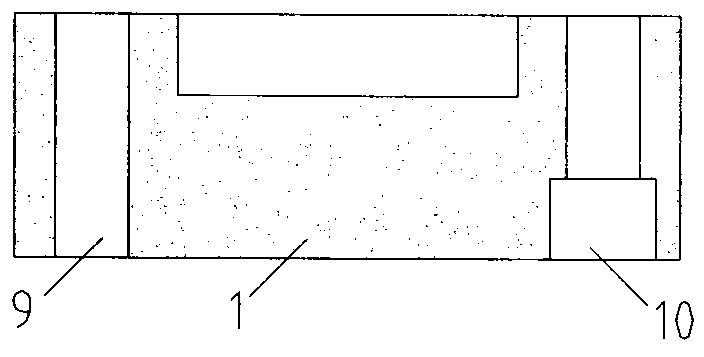

[0074] Basic data of the pile pipe: the outer diameter of the main pipe 2 is 600mm, the wall thickness is 25mm, and the height is 30m; the outer diameter of the pouring pipe 3 and the exhaust pipe 4 is 133mm, and the wall thickness is 10mm; 100mm, the remaining outer diameter is 113mm, and the wall thickness is 10mm; the correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com