Vibration immersed tube compaction pile model test device and test method

A model test device and model test technology, which is applied in the test of basic structure, construction, basic structure engineering, etc., can solve the problems of inaccurate measurement results, inability to give soil, and the sensor is easily disturbed by the external environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1: (transparent solid material is perfluorocyclic polymer)

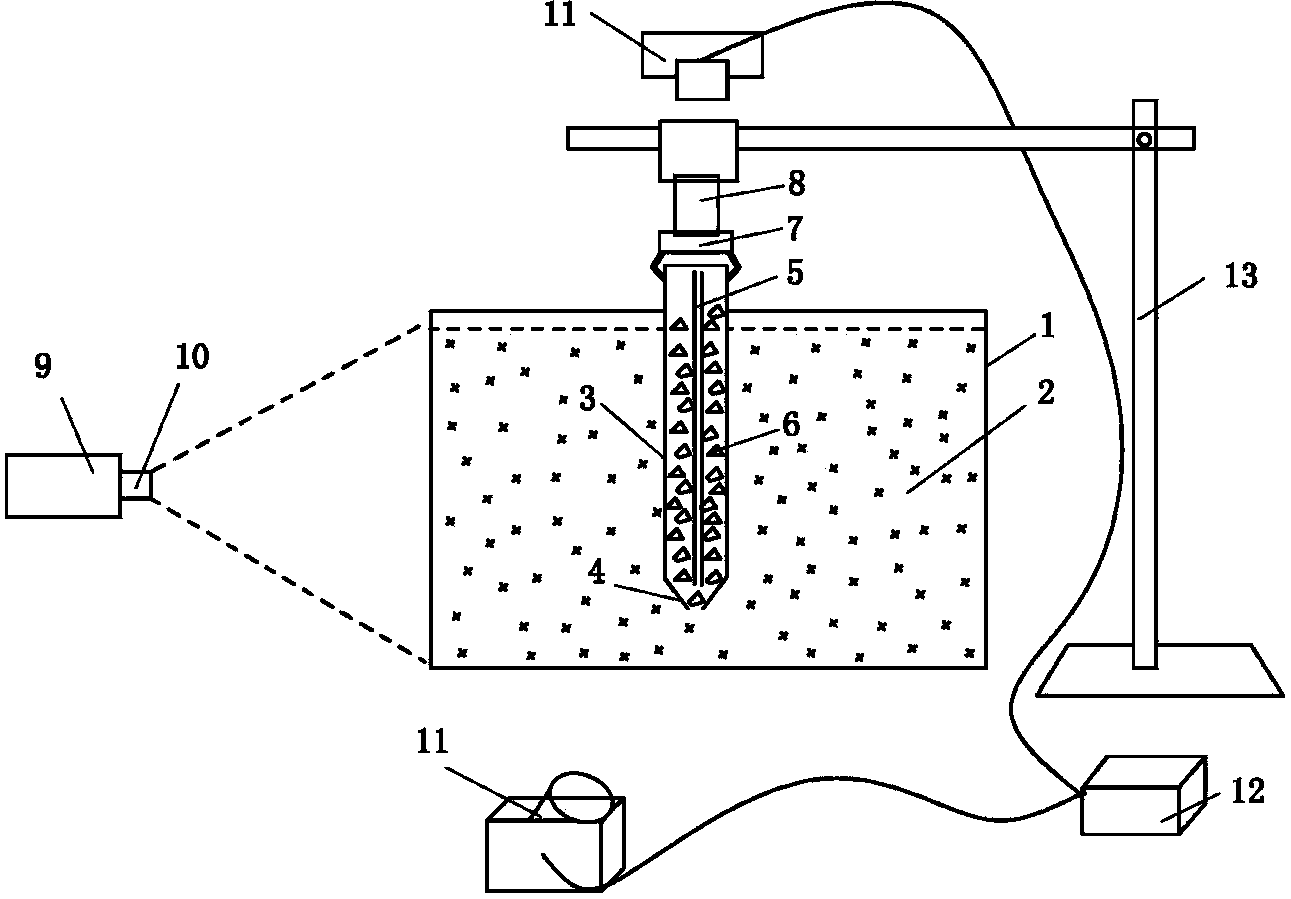

[0071] Depend on figure 1 It can be seen that a vibrating immersed tube compaction pile model test device includes a transparent model tank 1, which is provided with transparent soil simulating the soil around the pile 2, an immersed tube 3 with a pile shoe 4, and the center of the immersed tube 3 A grouting pipe 5 is provided, and a pile sinking mechanism installed on the support 13 is arranged on the top of the transparent model tank 1; Observing the digital camera 11 of the space of the transparent model tank 1, the digital camera 11 is connected with the processing device 12 through the data line; the laser beam irradiates the transparent model tank 1 to form a laser section forming the vertical or horizontal plane of the transparent model tank 1, which is recorded by the digital camera 11 The speckle field change and continuous deformation characteristics of the soil around the pile are analyz...

Embodiment 2

[0100] Embodiment 2: (transparent solid material is perfluorocyclic polymer)

[0101] In the process (1), select perfluorocyclic polymer particles 0.25㎜≤particle size<0.5㎜ as 10%, 0.5㎜≤particle size<1.0㎜ as 30%, and 1.0㎜≤particle size<1.5㎜ as 30% ﹪, 1.5㎜≤particle size≤2.0㎜ is 30%, the total is 100% by weight, and they are mixed evenly; the pore liquid is sodium chloride solution, and its concentration is 5%;

[0102] When mixing, first put the prepared pore liquid in the transparent model tank 1, and slowly, uniformly and dispersedly pour the perfluorocyclic polymer particles into the transparent model tank 1, and continuously stir to discharge the air bubbles during the pouring process. And keep the perfluorocyclic polymer particles always below the liquid level of the pore liquid;

[0103] The physical characteristics of the transparent soil made in this embodiment are: density 1.65g / ㎝ 3 , severe 17kN / m 3 , compactness 40%; mechanical properties: internal friction angle 3...

Embodiment 3

[0105] Embodiment 3: (transparent solid material is perfluorocyclic polymer)

[0106] In the process ⑴, select perfluorocyclic polymer particles 0.25㎜≤particle size<0.5㎜ as 10%, 0.5㎜≤particle size<1.0㎜ as 40%, and 1.0㎜≤particle size<1.5㎜ as 35% ﹪, 1.5㎜≤particle size≤2.0㎜ is 15%, the total is 100% by weight, and it is mixed evenly; the pore liquid is an alcohol solution, and its concentration is 15%;

[0107] When mixing, the density of the control sample is 40%.

[0108] The physical properties of the transparent soil made in this example are: density 1.83 g / ㎝ 3 , weight 17.5kN / m 3 , compactness 40%; mechanical properties: internal friction angle 31°, elastic modulus 15MPa, Poisson's ratio 0.32.

[0109] The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com