Full-automatic monitoring, early warning, temperature control, moisturizing and curing system and method for prefabricated immersed tube sections

A monitoring and early warning, fully automatic technology, which is applied in the field of moisturizing maintenance system and automatic temperature control, and can solve the problems of effective heat preservation, moisturizing and maintenance of unimmersed tube segments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

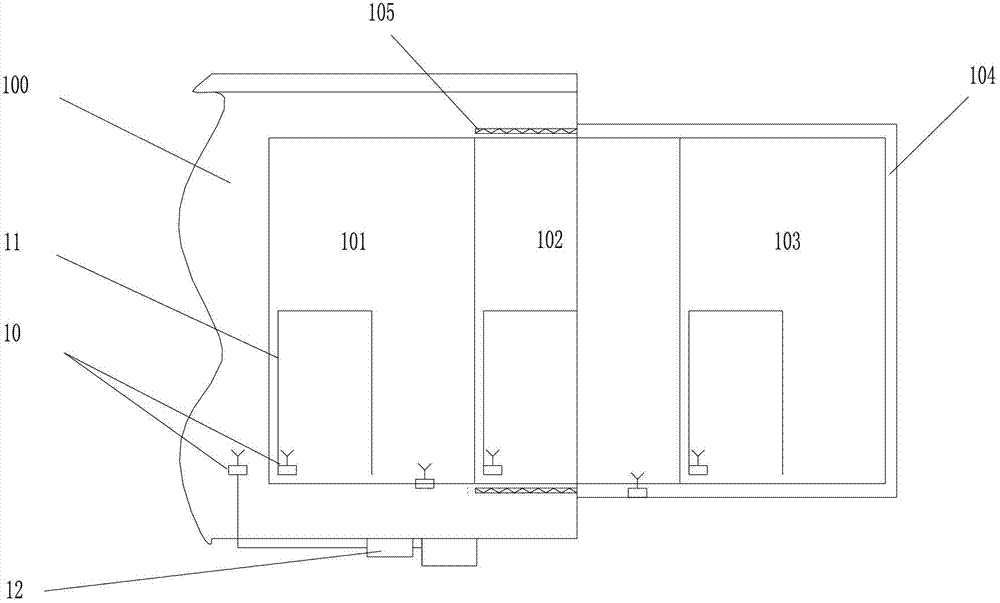

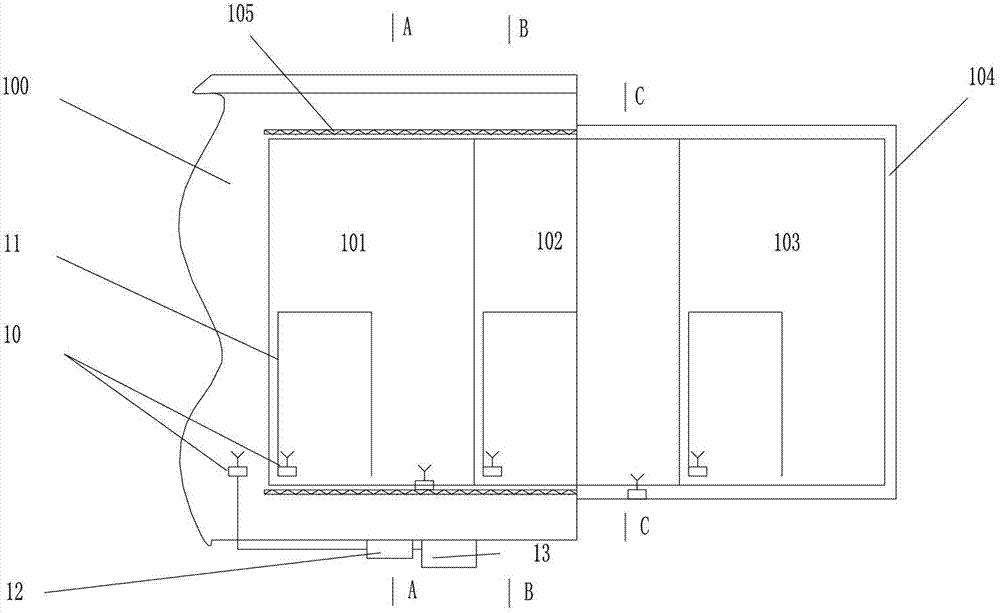

[0028] Figure 2~3 For the overall layout of the maintenance system, a folding curing shed and a fixed curing shed are set up in the direction of pushing forward of the outer segment of the prefabricated workshop of the production line to maintain the immersed tube segment. The maintenance system will cover the three immersed pipe sections respectively located in the pouring platform area 101 , the transition area 102 between the plant and the curing shed, and the curing shed area 103 .

[0029] The maintenance system includes the maintenance shed, temperature and humidity control system, sprinkler system and automatic control host, etc. The curing shed is formed by connecting a foldable curing shed 105 arranged in the prefabricated factory building and a fixed curing shed 16 arranged outside the prefabricated factory building. Among them, the folding curing shed 105 can simultaneously maintain a segment located in the pouring platform area 101 and a half-section segment loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com