Immersed tube drainage structure and method for handling suddenly-produced foundation pit water bursting and fountains through immersed tube drainage structure

A sudden, immersed tube technology, applied in immersed tube precipitation treatment of sudden foundation pit water surge, immersed tube precipitation structure, fountain field, can solve the problems of low porosity, scrapped wells, large amount of engineering, etc. Simple and effective in reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples are only used to illustrate the present invention, but not to limit the protection scope of the present invention.

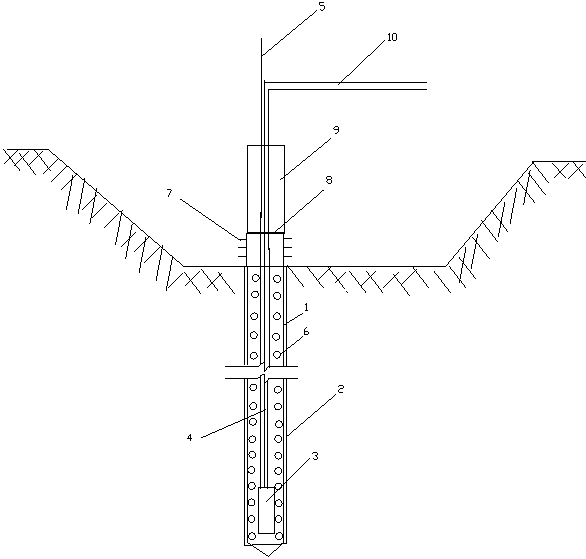

[0020] Such as figure 1 As shown, an immersed tube dewatering structure of the present invention includes a steel pipe 1, a submersible pump 3, a water pipe 4 and a drain pipe 10, and the water suction hole 6 is drilled on the steel pipe 1 wall, and the water suction hole 6 is drilled by a drilling tool , the operation on the ground is quite convenient. In addition, the water absorption hole 6 has two functions. On the one hand, it can make water enter quickly from the water absorption hole 6 instead of only relying on a steel pipe mouth; on the other hand, the water absorption hole 6 is wrapped with nylon tight Mesh 2, make water can enter, and the silt that is greater than the aperture of nylon dense mesh can not enter, and silt is just deposited at the bottom of the pit.

[0021] The steel pipe 1 is located on the upper surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com