Preparation method of carbon nano-tube reinforced foamed aluminum filled aluminum alloy pipe composite structure

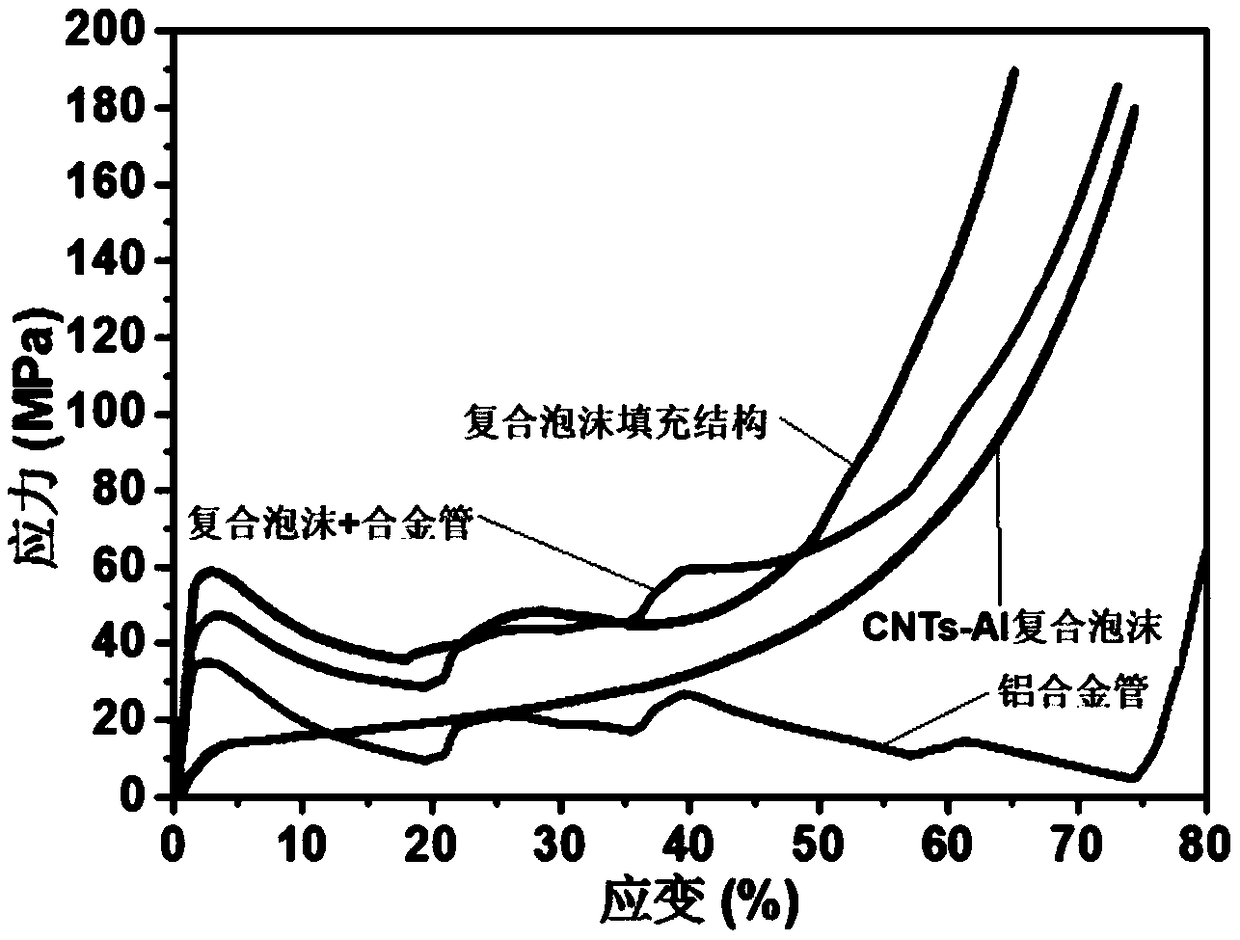

A technology of aluminum alloy tubes and carbon nanotubes, which is applied in the field of filling structure preparation, can solve problems such as difficulty in achieving uniform dispersion, CNTs agglomeration, and CNTs structure damage, and achieve enhanced shock absorption and energy absorption effects, uniform pore size and pore diameter Precise control, high energy absorption and shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

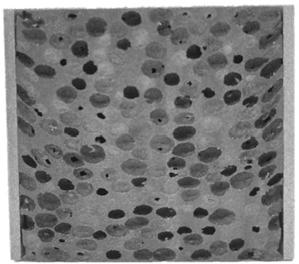

[0026] The preparation method of the open-cell CNTs / Al composite foam in this example includes the following steps: (1) adding aluminum powder and cobalt nitrate hexahydrate into absolute ethanol whose mass is 7 times that of aluminum powder according to the mass ratio of 40:1 . Ultrasound was used to accelerate the dissolution of cobalt nitrate, and then stirring was continued in a water bath at 60°C until ethanol evaporated completely. The obtained mixture was dried in an oven at 80° C. for 8 hours. The obtained completely dried powder was placed in a tube furnace, heated to 250°C under the protection of argon, switched to hydrogen with a flow rate of 200ml / min, and kept at 250°C and 450°C for 1 hour respectively. Then close the hydrogen, raise the temperature to 600°C under the protection of argon, and pass the mixed gas of acetylene and argon in the ratio of 1:12, react at 600°C for 30m minutes, finally close the mixed gas, Cool to room temperature under the protection o...

Embodiment 2

[0034]The preparation method of the open-cell CNTs / Al composite foam in this example includes the following steps: (1) adding aluminum powder and cobalt nitrate hexahydrate to absolute ethanol whose mass is 10 times that of aluminum powder according to the mass ratio of 80:1 . Ultrasound was used to accelerate the dissolution of cobalt nitrate, and then stirring was continued in a water bath at 60°C until ethanol evaporated completely. The obtained mixture was dried in an oven at 80° C. for 8 hours. In the obtained completely dried powder tube furnace, the temperature was raised to 250°C under the protection of argon, switched to hydrogen with a flow rate of 250ml / min, and kept at 250°C and 450°C for 1 hour respectively. Then turn off the hydrogen, raise the temperature to 600°C under the protection of argon, and pass the mixed gas of acetylene and argon in the ratio of 1:12, react at 600°C for 60m minutes, finally turn off the mixed gas, and in argon Cool to room temperatur...

Embodiment 3

[0041] The preparation method of the open-cell CNTs / Al composite foam in this example includes the following steps: (1) adding aluminum powder and cobalt nitrate hexahydrate to absolute ethanol whose mass is 8 times that of aluminum powder according to the mass ratio of 120:1 . Ultrasound was used to accelerate the dissolution of cobalt nitrate, and then stirring was continued in a water bath at 60°C until ethanol evaporated completely. The obtained mixture was dried in an oven at 80° C. for 8 hours. The obtained dried powder was placed in a tube furnace, heated to 250°C under the protection of argon, switched to hydrogen with a flow rate of 240ml / min, and kept at 250°C and 450°C for 1 hour respectively. Then turn off the hydrogen, raise the temperature to 600°C under the protection of argon, and pass the mixed gas of acetylene and argon in the ratio of 1:12, react at 600°C for 60m minutes, finally turn off the mixed gas, and in argon Cool to room temperature under the prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com