Grating

A grid and longitudinal rib technology, applied in the field of manufacturing the above-mentioned types of covered grids, can solve the problems of inability to further reduce the thickness of the plate, insufficient load transfer, and low connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

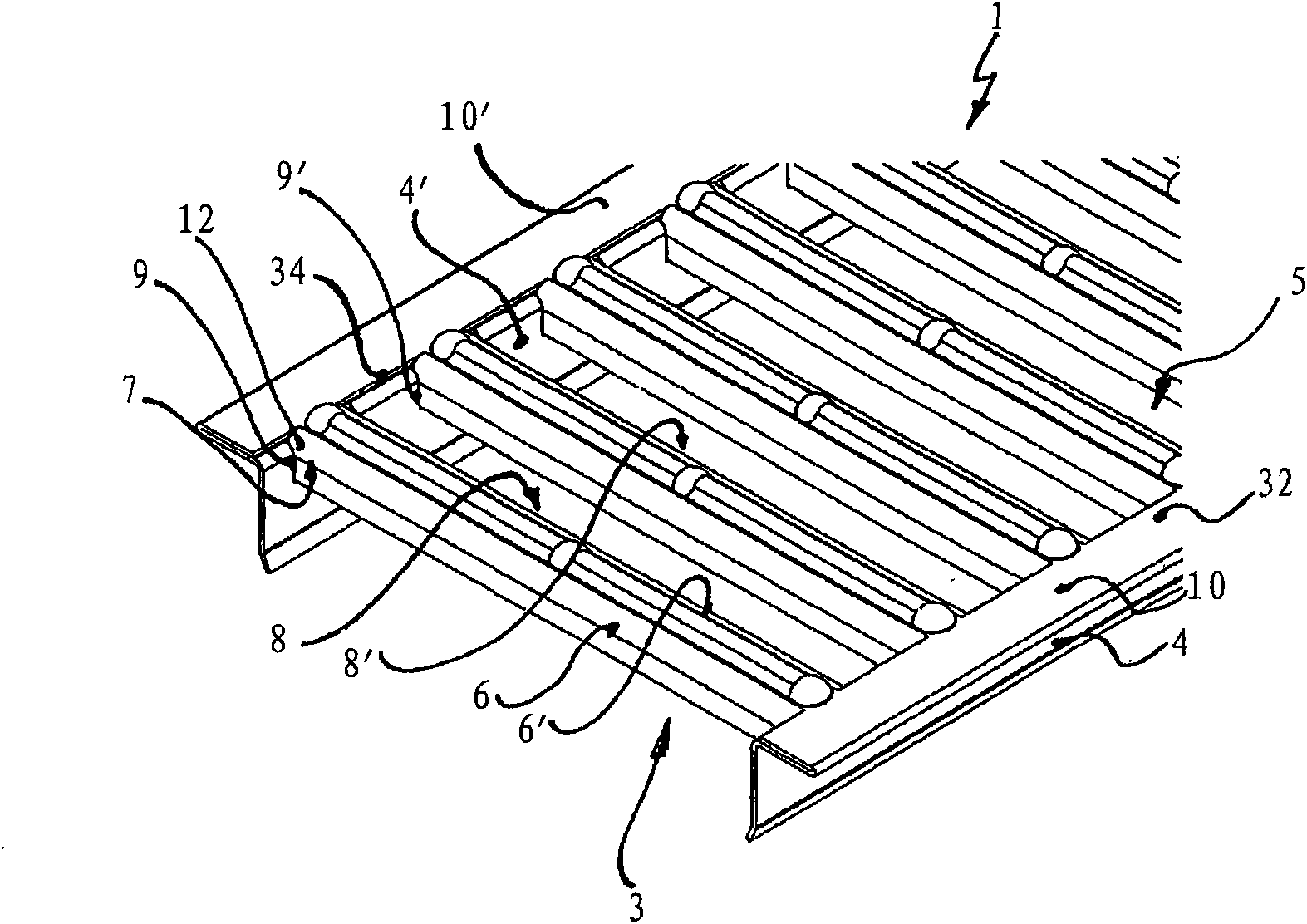

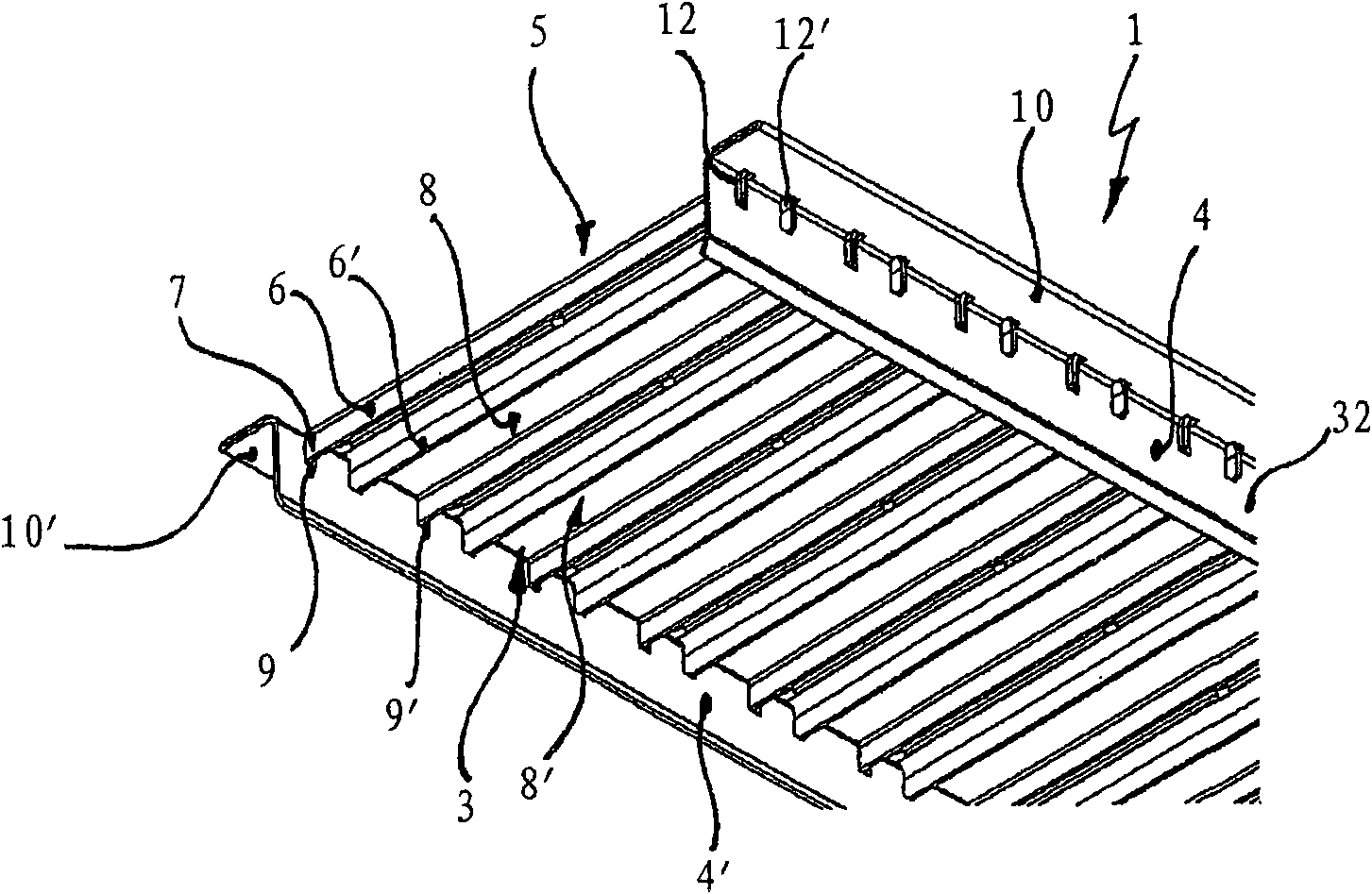

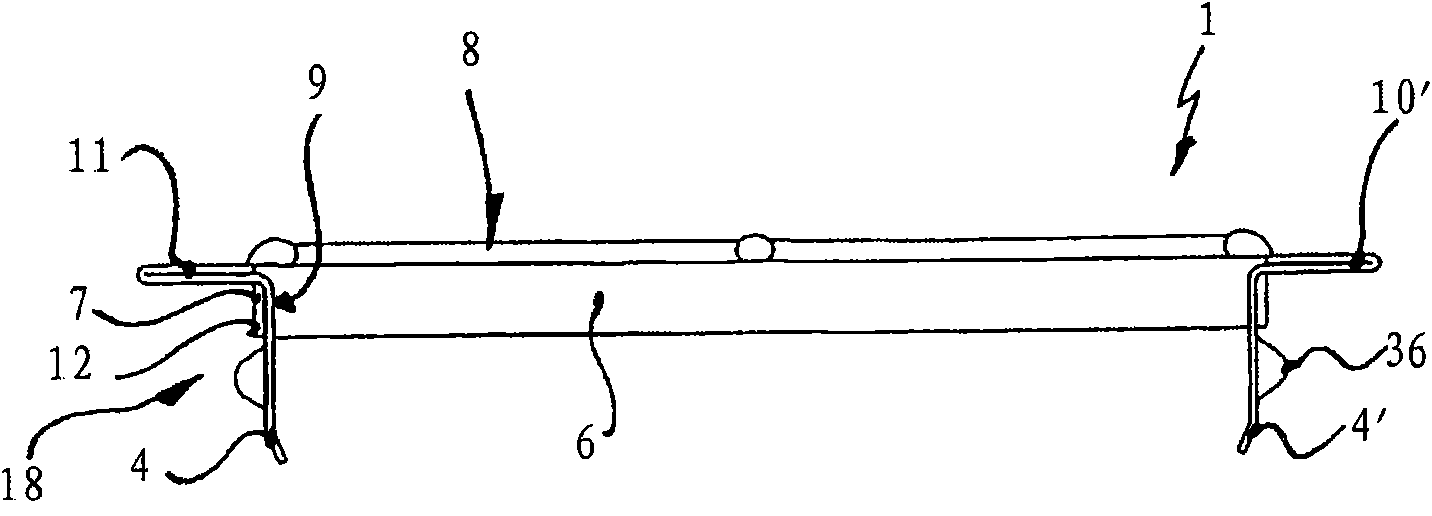

[0031] figure 1 with figure 2 Each shows an isometric view of a first embodiment of a covering grid 1 according to the invention. The cover grid shown here is formed by flanging a sheet metal 32 and has longitudinal ribs 4 formed in one piece with the cover grid 1 . The longitudinal ribs 4 are formed from a sheet metal that has been folded several times, thereby additionally forming a support area 10 for laying the covering grate 1 on a drainage pipe (not shown).

[0032] Furthermore, the cover grid 1 has a plurality of inflow channels 8 which can be used in particular for conducting surface water or the like. Basically, the term inflow slot is intended to be understood as meaning almost any inflow opening extending essentially between two longitudinal ribs 4 of the cover grid 1 .

[0033] In this case, the inflow channels 8 are stamped and formed from sheet metal 32 and each have two transverse ribs 6 which each extend parallel to the inflow channels 8 on the underside 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com