Preparation method of high-heat-insulation, high-pressure-resistance, low-density and heat-resistant composite epoxy foam

A low-density, heat-resistant technology, applied in the field of epoxy resin, can solve the problems of difficulty in matching the foaming process, and it is difficult to further improve the heat resistance and compressive strength of epoxy foam, and achieve compressive performance and heat resistance. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The organic dispersant is N, N-dimethylformamide, the diisocyanate is toluene diisocyanate, the organometallic catalyst ① is dibutyltin dilaurate, the organometallic catalyst ② is tetraisobutyl titanate, and the epoxy resin is Silicone epoxy resin, diethyl toluene diamine is selected as amine curing agent, 3,3'-disulfonyl hydrazide diphenyl sulfone is selected as foaming agent, octylphenol polyoxyethylene ether is selected as surfactant, toughening The agent is selected from epoxy-based nitrile rubber, and the specific operation steps are as follows:

[0023] (1) Synthesis process of modified graphene oxide: graphene oxide was added to N, N-dimethylformamide to prepare a suspension with a mass fraction of 0.005 g / ml, and the solvent was first dehydrated through 4A molecular sieve. The suspension was subjected to ultrasonic treatment for 1 h to facilitate dispersion, the ultrasonic power was 100 kW, and the temperature of the water bath was 25°C. Then, a mixed solution ...

Embodiment 2

[0033] The organic dispersant is N, N-dimethylformamide, the diisocyanate is toluene diisocyanate, the organometallic catalyst ① is dibutyltin dilaurate, the organometallic catalyst ② is tetraisobutyl titanate, and the epoxy resin is Silicone epoxy resin, diethyl toluene diamine is selected as amine curing agent, 3,3'-disulfonyl hydrazide diphenyl sulfone is selected as foaming agent, octylphenol polyoxyethylene ether is selected as surfactant, toughening The agent is selected from epoxy-based nitrile rubber, and the specific operation steps are as follows:

[0034] (1) Synthesis process of modified graphene oxide: graphene oxide was added to N, N-dimethylformamide to prepare a suspension with a mass fraction of 0.005 g / ml, and the solvent was first dehydrated through 4A molecular sieve. The suspension was subjected to ultrasonic treatment for 1 h to facilitate dispersion, the ultrasonic power was 100 kW, and the temperature of the water bath was 25°C. Then, a mixed solution ...

Embodiment 3

[0042] The organic dispersant is N, N-dimethylformamide, the diisocyanate is toluene diisocyanate, the organometallic catalyst ① is dibutyltin dilaurate, the organometallic catalyst ② is tetraisobutyl titanate, and the epoxy resin is Silicone epoxy resin, diethyl toluene diamine is selected as amine curing agent, 3,3'-disulfonyl hydrazide diphenyl sulfone is selected as foaming agent, octylphenol polyoxyethylene ether is selected as surfactant, toughening The agent is selected from epoxy-based nitrile rubber, and the specific operation steps are as follows:

[0043] (1) Synthesis process of modified graphene oxide: graphene oxide was added to N, N-dimethylformamide to prepare a suspension with a mass fraction of 0.005 g / ml, and the solvent was first dehydrated through 4A molecular sieve. The suspension was subjected to ultrasonic treatment for 1 h to facilitate dispersion, the ultrasonic power was 100 kW, and the temperature of the water bath was 25°C. Then in a nitrogen atmo...

PUM

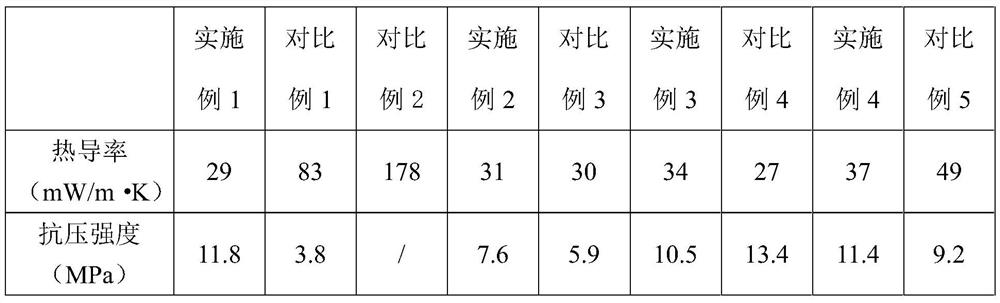

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com