Foldable metal wall frame assemblies for use in residential and commercial structures

a technology of metal wall frame and prefabricated frame, which is applied in the direction of girders, walls, joists, etc., can solve the problems of existing roll forming technology, slow progress, and moderate increase, and achieve the effect of enhancing the transfer of structural loads and ensuring reliable load transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

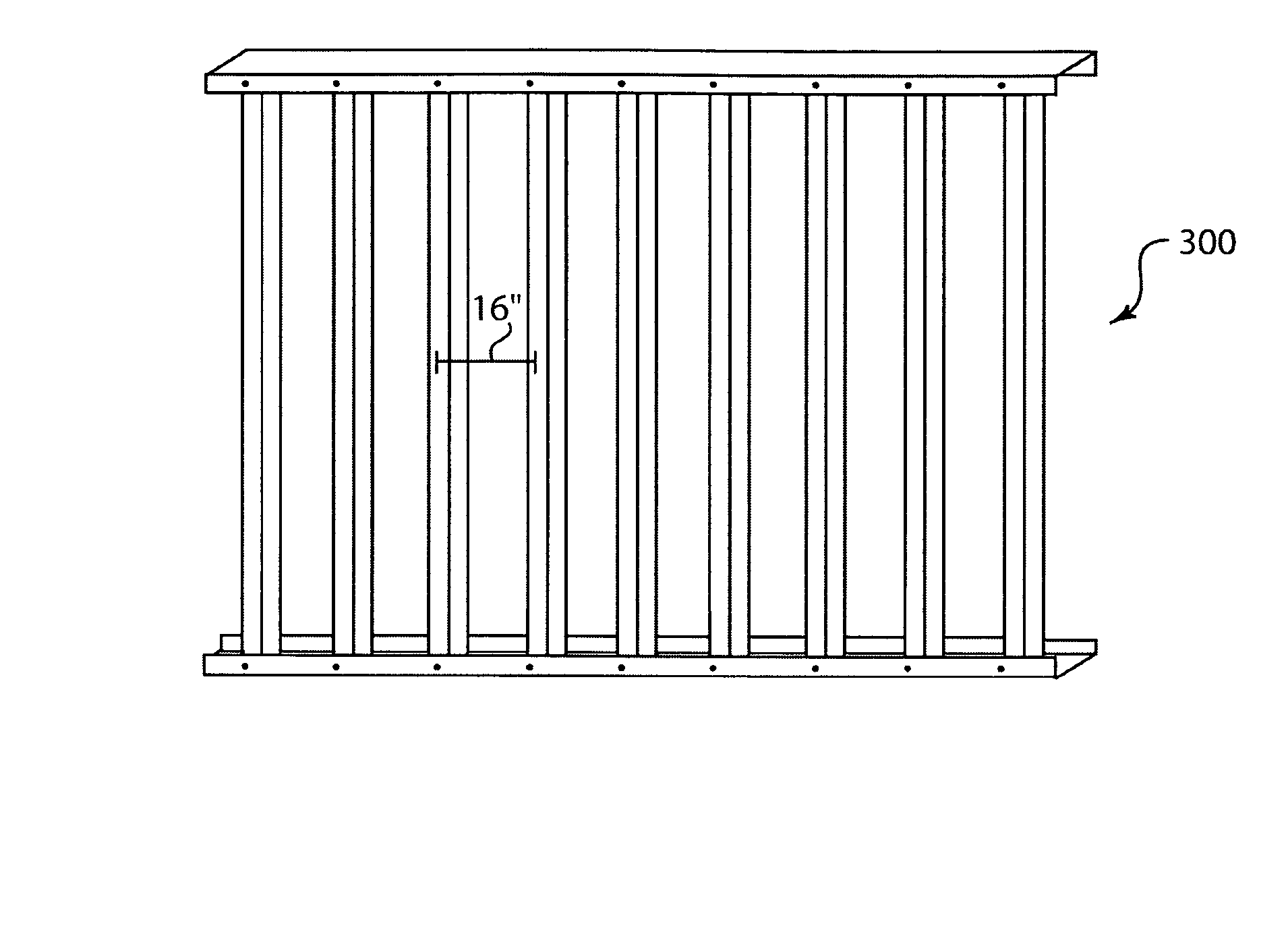

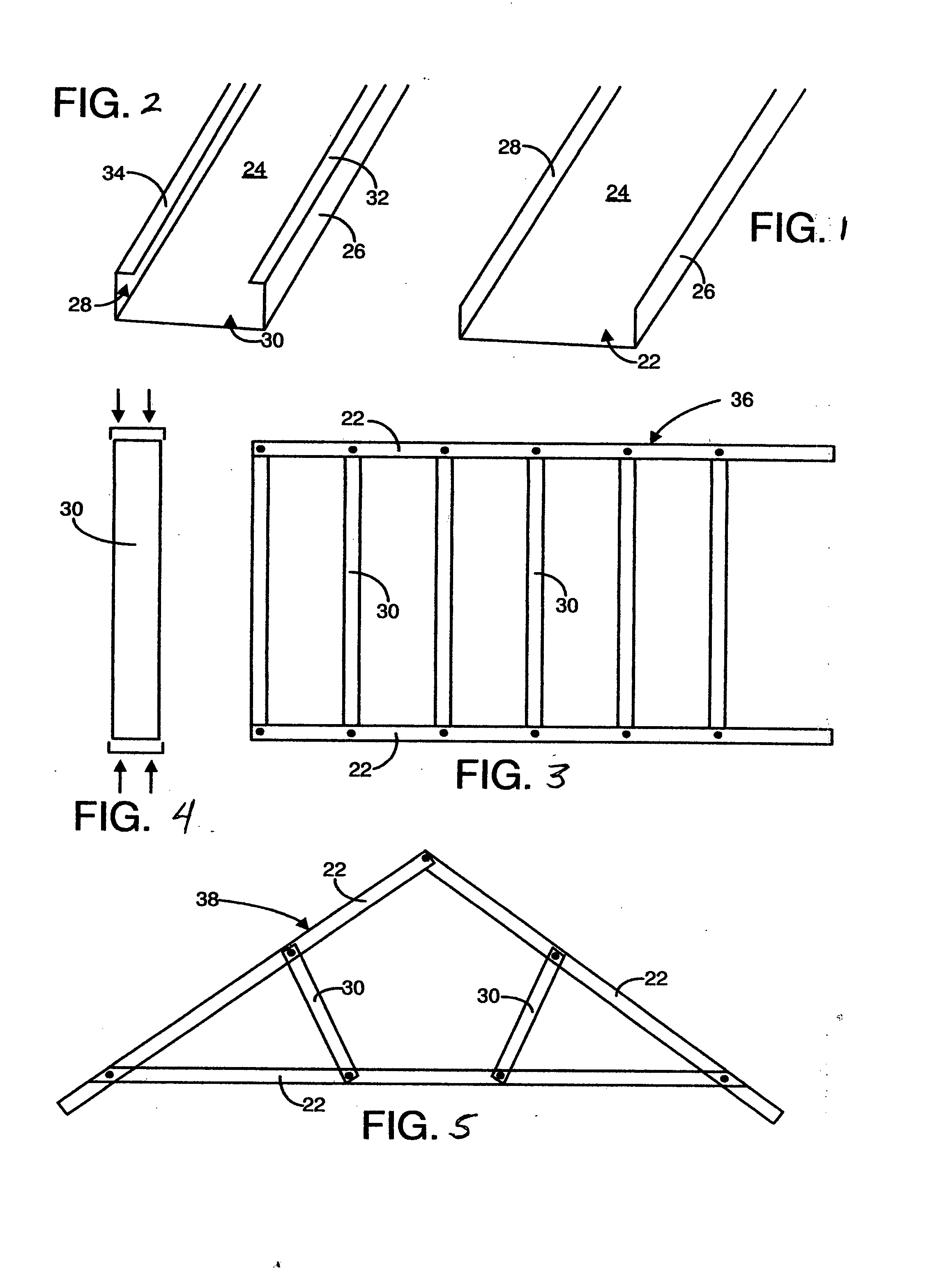

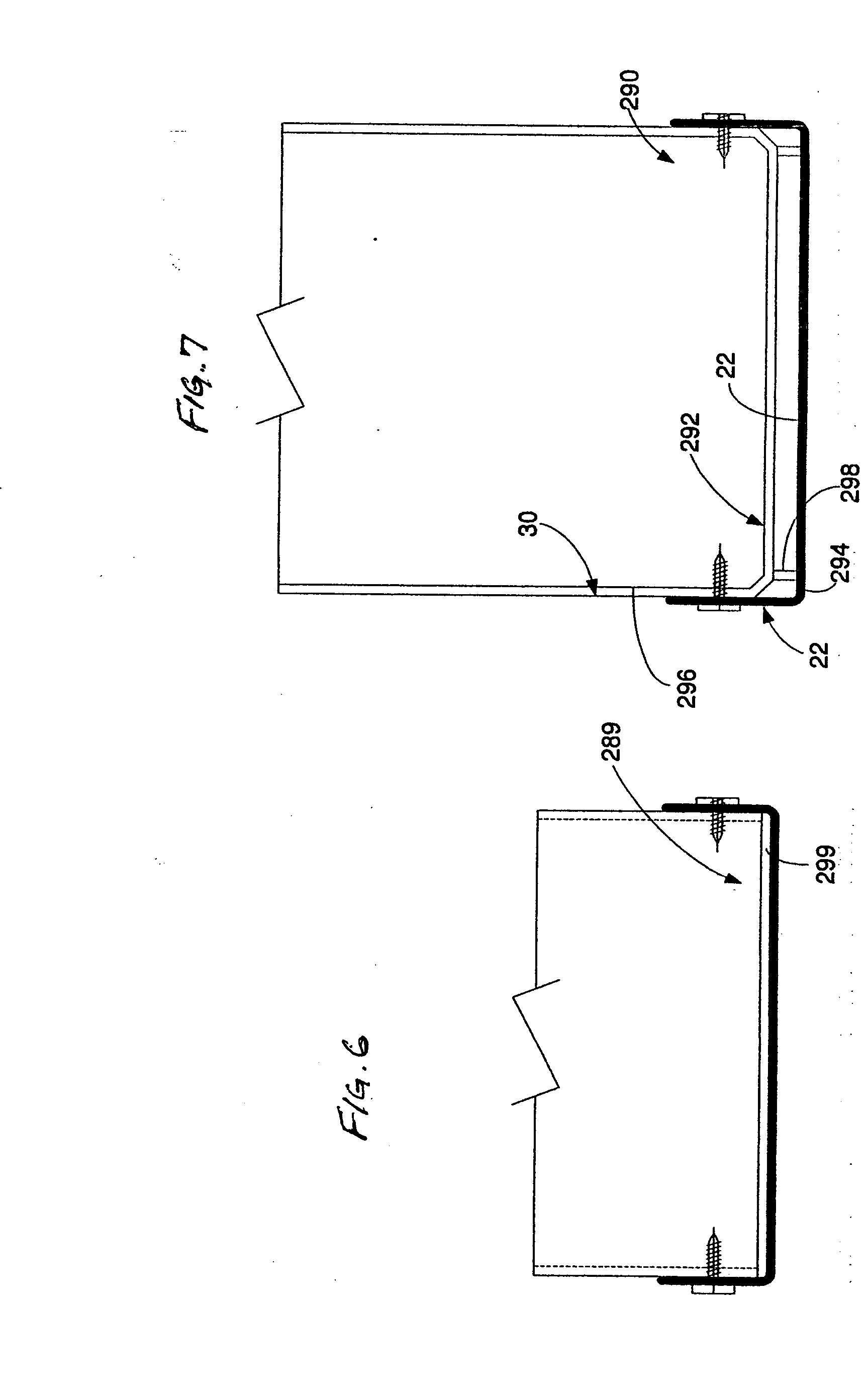

[0063] The present invention is a multifaceted foldable metal wall frame arrangement for residential and commercial building frames and the assembling of building structures therefrom. Referring first to FIGS. 1-5, metal sheets may be formed using any desired process into metal frame components, but preferably using the process and apparatus of the above-referenced related pending patent application. In the present invention, substantially U-shaped metal frame components are utilized and interconnected for use in residential and commercial building frame structures. One of the primary components formed using the present invention is a metal track member 22 having a center web portion 24 and a pair of upright flanges 26, 28 that are preferably angled at approximately 90° relative to the web portion 24. The other primary component in a metal wall frame is a stud element 30. The stud element 30 includes a center web portion 24 having upright flanges 26, 28 as in the track member 22. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| curvature radius | aaaaa | aaaaa |

| relative movement | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com