Titanium-silicon-carbon interface modified SiCf/SiC wave-absorbing composite material and preparation method thereof

A composite material, titanium silicon carbon technology, used in magnetic field/electric field shielding, electrical components and other directions, can solve the problems of inability to achieve electromagnetic wave absorption, poor wave absorption performance, etc., to achieve inhibition of volume shrinkage, good wave absorption performance, and reduce agglomeration phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

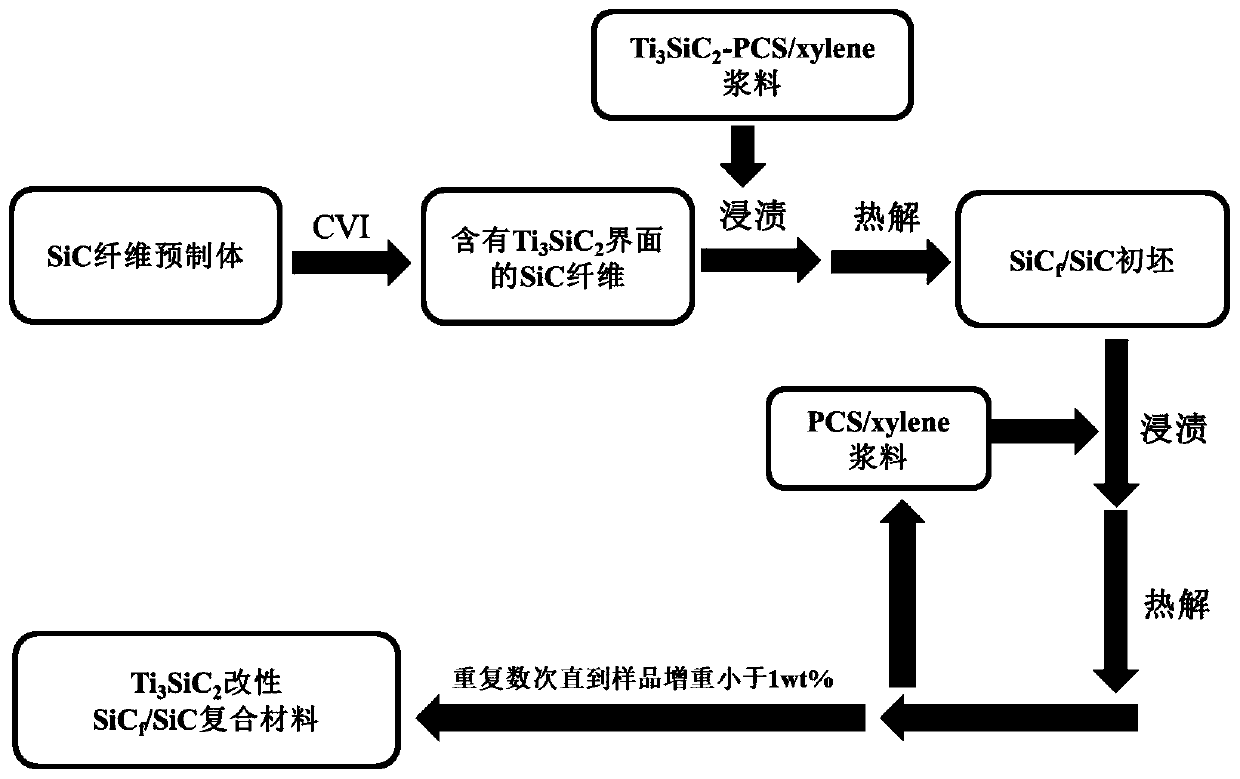

[0026] A preparation method of titanium silicon carbon interface modified SiCf / SiC wave-absorbing composite material, comprising the following steps (such as figure 1 shown):

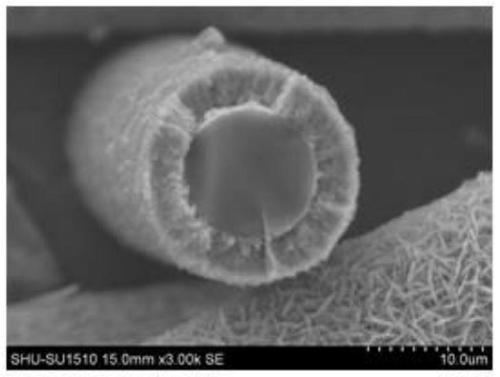

[0027] Step 1. Prepare Ti on the surface of 3D4d silicon carbide fiber fabric by chemical vapor infiltration process 3 SiC 2 interfacial phase, the TiCl 4 and H 2 As a precursor system, Ar is passed into the chemical vapor deposition furnace as a diluent gas and a protective gas, where H 2 and TiCl 4 The molar ratio is 20, the hydrogen flow rate is 500 sccm, the argon gas flow rate is 500 sccm, and the temperature is 1100 °C and the pressure is 8 kPa, and it is deposited for 5 hours to form a silicon carbide fiber fabric reinforcement containing an interface phase.

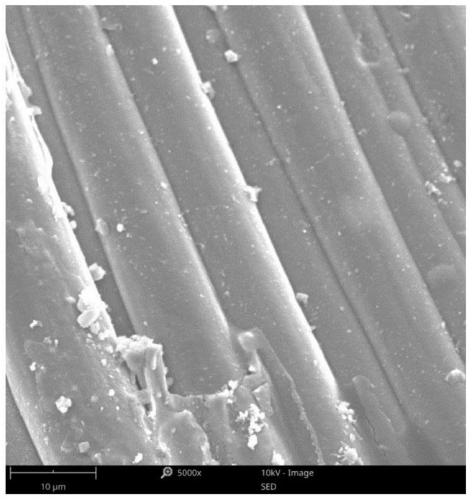

[0028] Step 2, dissolve polycarbosilane solid particles in xylene to form a solution, add a certain amount of Ti 3 SiC 2 Filler, as a slurry for the first impregnation, Ti 3 SiC 2into the SiC matrix. The amount of titanium-silicon...

Embodiment 2

[0032] A method for preparing a titanium-silicon-carbon interface modified SiCf / SiC wave-absorbing composite material, comprising the following steps:

[0033] Step 1. Prepare Ti on the surface of the 2D laminated silicon carbide fiber fabric by chemical vapor infiltration process 3 SiC 2 interfacial phase, the TiCl 4 and H 2 As a precursor system, Ar is passed into the chemical vapor deposition furnace as a diluent gas and a protective gas, where H 2 and TiCl 4 The molar ratio is 10, the hydrogen flow rate is 350 sccm, the argon gas flow rate is 450 sccm, and the temperature is 1200 °C and the pressure is 6 kPa a, and it is deposited for 7 hours to form a silicon carbide fiber fabric reinforcement containing an interface phase.

[0034] Step 2, dissolve polycarbosilane solid particles in xylene to form a solution, add a certain amount of Ti 3 SiC 2 Filler, as a slurry for the first impregnation, Ti 3 SiC 2 into the SiC matrix. The amount of titanium silicon carbon fi...

Embodiment 3

[0038] A method for preparing a titanium-silicon-carbon interface modified SiCf / SiC wave-absorbing composite material, comprising the following steps:

[0039] Step 1, prepare Ti on the surface of 2.5D silicon carbide fiber fabric by chemical vapor infiltration process 3 SiC 2 interfacial phase, the TiCl 4 and H 2 As a precursor system, Ar is passed into the chemical vapor deposition furnace as a diluent gas and a protective gas, where H 2 and TiCl 4 The molar ratio is 10, the flow rate of hydrogen gas is 700 sccm, the flow rate of argon gas is 800 sccm, and the temperature is 900 °C and the pressure is 4 kPa, and it is deposited for 9 hours to form a silicon carbide fiber fabric reinforcement containing an interface phase

[0040] Step 2, dissolve polycarbosilane solid particles in xylene to form a solution, add a certain amount of Ti 3 SiC 2 Filler, as a slurry for the first impregnation, Ti 3 SiC 2 into the SiC matrix. The amount of titanium-silicon-carbon filler a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com