Wave suction composite material with nanocrystalline structure and method for producing the same

A composite material and nanocrystalline technology, applied in the field of wave-absorbing materials, can solve the problems of unfavorable electromagnetic wave absorption, easy generation of eddy current, large dielectric constant, etc., and achieve the effects of anti-oxidation, low cost, wide shielding band, and high frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

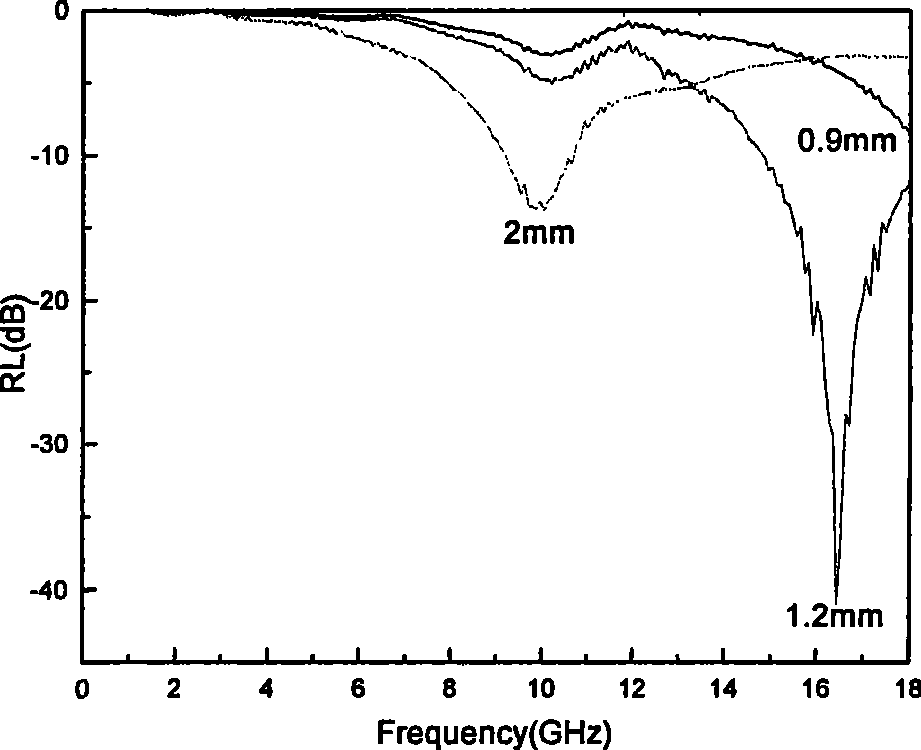

[0031] Melt 25 parts by weight of samarium and 75 parts by weight of pure iron into an ingot under the protection of argon, heat-treat at 1200°C for 4 hours, then explode with hydrogen at 200°C for 1 hour, break into powder, and hydrogenate at 700°C Disproportionation + recombination (HDDR) for 1 hour, nitriding at 600°C for 2 hours to prepare a SmFeN permanent magnet material, decomposing the magnetic powder at a temperature of 700°C for 20 minutes to obtain a SmFeN / α-Fe / SmN composite material, and then ball milling and flattening After chemical treatment, the alloy powder and paraffin were mixed in a weight ratio of 5:1, and then pressed into a ring shape (D=7mm, d=3.01mm, h=3mm), the magnetic permeability of the sample μ r , dielectric constant ε r Measured with Agilent E8720 electromagnetic wave vector network analyzer. The imaginary part of the permittivity ε″ reaches 14 at a frequency of 5GHz, the real part of the permeability μ′ is up to 2.9, the imaginary part of the ...

Embodiment 2

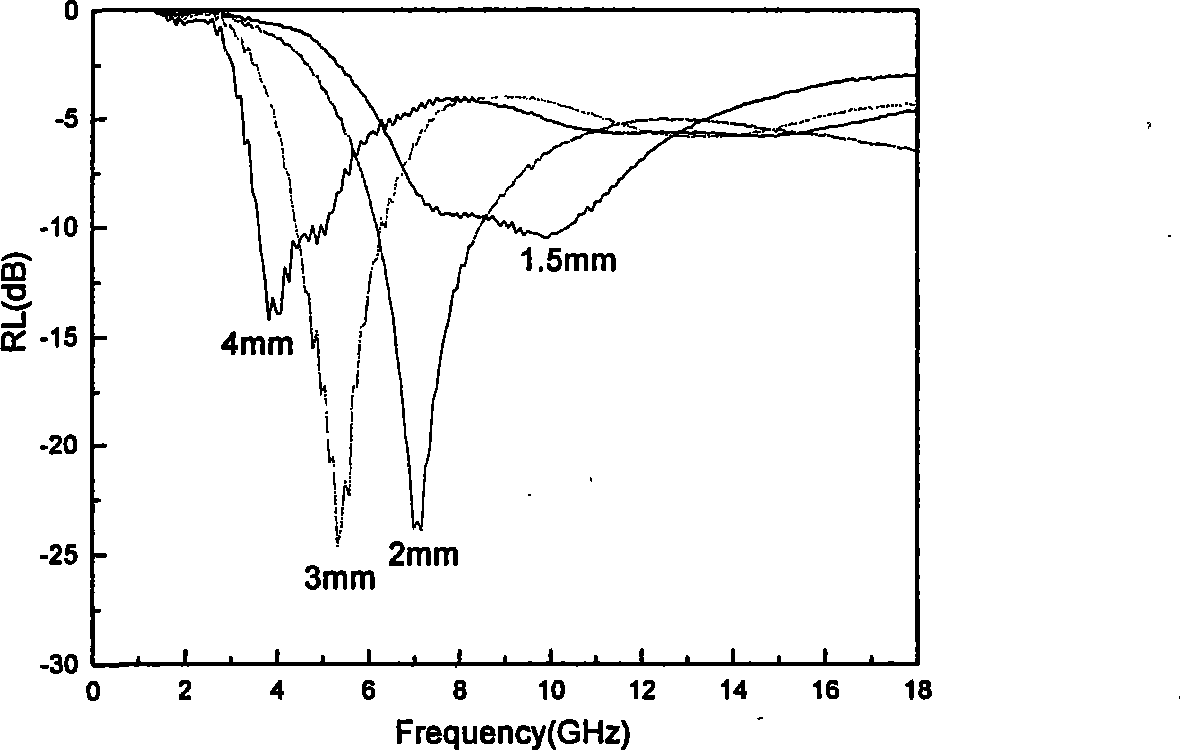

[0033] 2 parts by weight of samarium and 98 parts by weight of pure iron were melted into ingots under the protection of argon, and after heat treatment at 700°C for 60 hours, hydrogenation disproportionation + recombination (HDDR) at 650°C for 2 hours to prepare nanocrystals SmFe / α-Fe / SmHx was nitrided at 400°C for 40 hours to form a SmFeN / α-Fe / SmN composite material, and after ball milling and flattening, the alloy powder and paraffin were mixed in a weight ratio of 5:1. Then pressed into a ring shape (D=7mm, d=3.01mm, h=3mm), the electromagnetic parameter μ of the sample r , ε r Measured by the Agilent E8720 electromagnetic wave vector network analyzer, ε″ reaches 13 at a frequency of 6GHz, μ′ reaches a maximum of 3.2, μ″ reaches a maximum of 1.0, its absorption peak reaches -25 decibels (dB), and the absorption rate is less than -10dB The bandwidth is 2.5GHz, the absorbing curve is detailed in figure 2 shown.

Embodiment 3

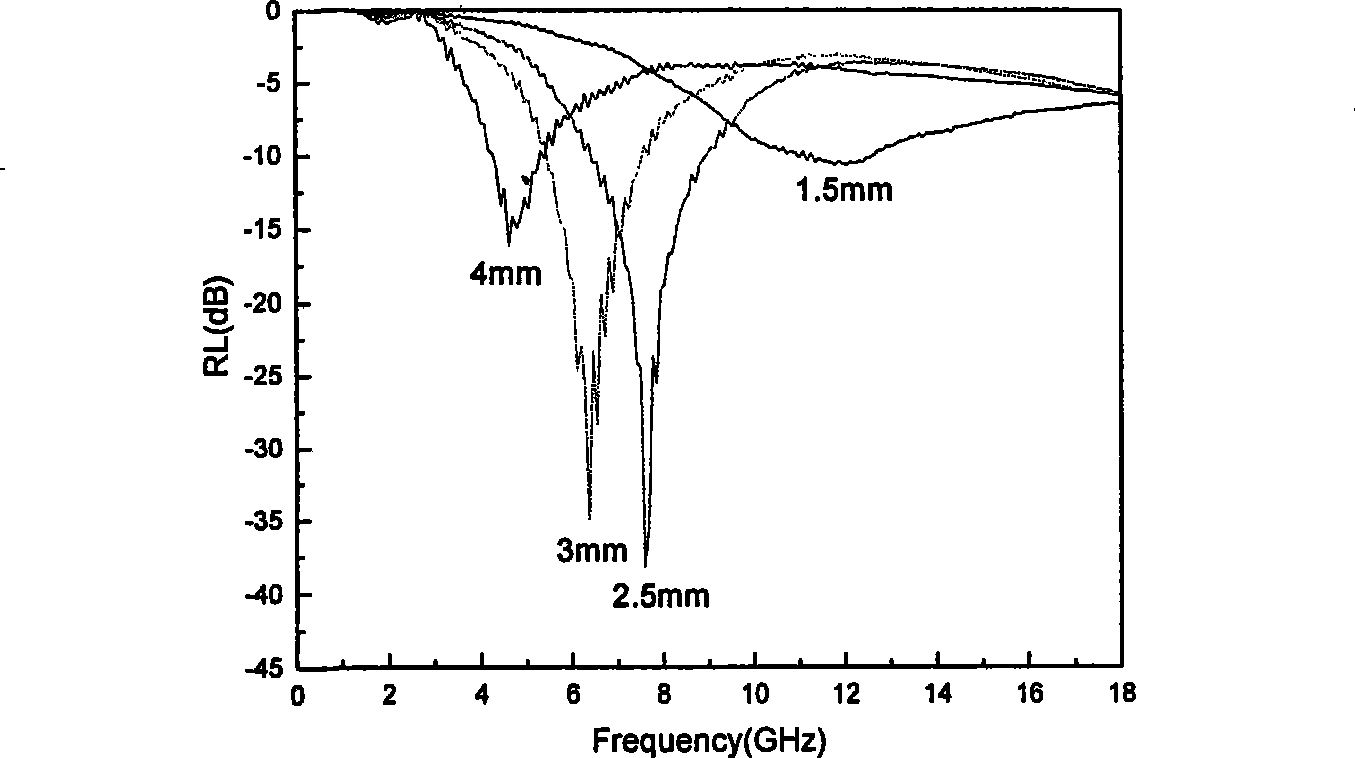

[0035] 14 parts by weight of samarium, 6 parts by weight of neodymium and 80 parts by weight of pure iron were melted into ingots under the protection of argon, and after heat treatment at a temperature of 1000 ° C for 10 hours, hydrogen disproportionation + recombination (HDDR) at a temperature of 750 ° C for 5 hours , and then nitriding at a temperature of 600°C for 2 hours to prepare a NdFeN / SmFeN permanent magnet material, and then decomposing the magnetic powder at a temperature of 720°C for 20 minutes to obtain a SmFeN / NdFeN / α-Fe / NdN / SmN composite material, and then ball milling After flattening treatment, the alloy powder and paraffin are mixed in a weight ratio of 5:1, and then pressed into a ring shape (D=7mm, d=3.01mm, h=3mm), the electromagnetic parameter μ of the sample r , ε rMeasured by the Agilent E8720 electromagnetic wave vector network analyzer, ε″ reaches 10 at a frequency of 3GHz, μ′ reaches a maximum of 3.5, μ″ reaches a maximum of 1.2, its absorption peak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com