High-efficiency soft magnetic composite material and preparation method thereof

A soft magnetic composite material and composite material technology, applied in the field of high-efficiency soft magnetic composite materials and their preparation, can solve the problems of soft magnetic composite materials that cannot be sintered, the internal stress of the insulating layer is damaged, and the insulating film is easy to be brittle. Structural parameters are controllable, eddy current resistance is improved, and stress is thoroughly eliminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

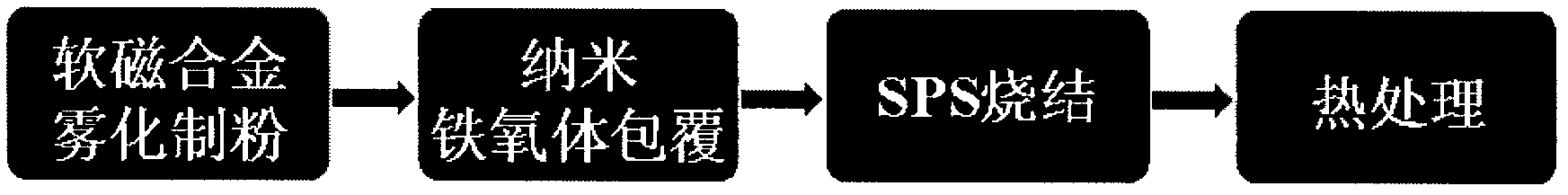

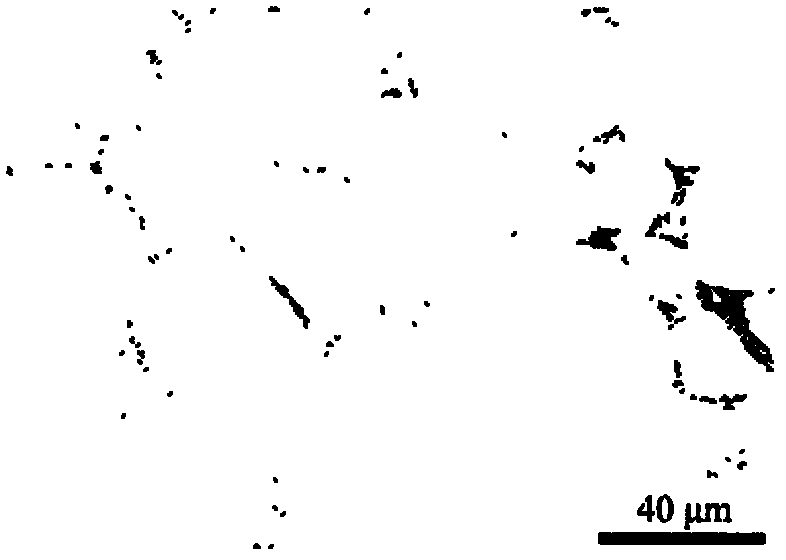

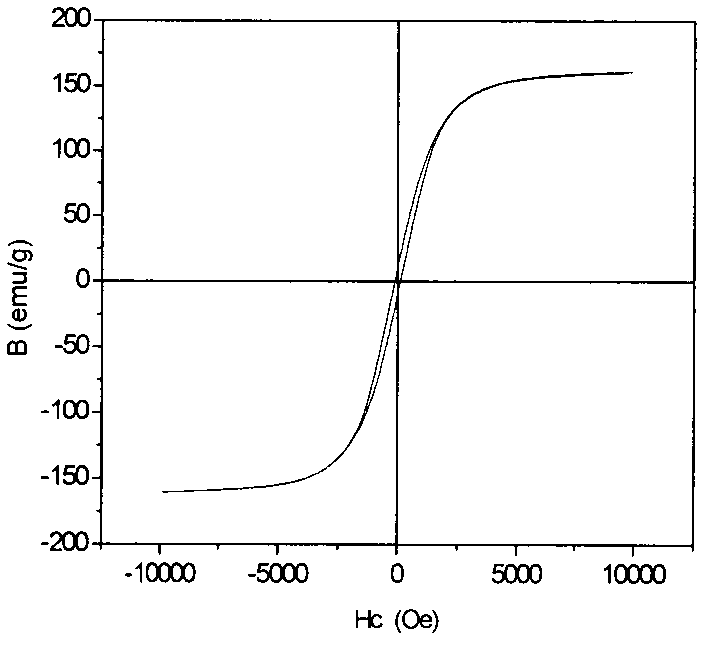

[0047] The preparation process is as figure 1 As shown, the Fe-based alloy was first gas-atomized, and the prepared powder was sieved. Mixed particle size aerosolized powder and commercially available nano soft magnetic Zn with a particle size below 63 μm 0.5 Ni 0.5 Fe 2 o 4 Ferrite powder is the raw material. Fe-based alloy powder and Zn 0.5 Ni 0.5 Fe 2 o 4 Nanopowder is mixed by 19:1 (weight ratio), grinds and makes Zn 0.5 Ni 0.5 Fe 2 o 4 The nanometer powder is evenly coated on the surface of the Fe-based alloy powder, and the blank is cold-pressed for SPS sintering. The SPS test was carried out on the SPS-1050 spark plasma sintering machine of Sumitomo Company, using a cemented carbide mold with an inner diameter of 15mm. Graphite paper is placed between the female mold and the male mold and between the male mold and the sample. After pre-tightening, the galvanic temperature measurement hole and the center of the sample are at the same height to ensure that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com