Block amorphous/ferrite soft magnetic composite material and preparation method thereof

A soft magnetic composite material and ferrite technology, applied in the direction of magnetic materials, inorganic material magnetism, magnetic objects, etc., can solve the problem that soft magnetic composite materials cannot be sintered, the filling degree of powder core is difficult to reach high, and the saturation magnetic induction intensity is reduced. and other problems, to achieve the effects of controllable microstructural parameters, excellent comprehensive mechanical properties, and high saturation magnetic induction intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

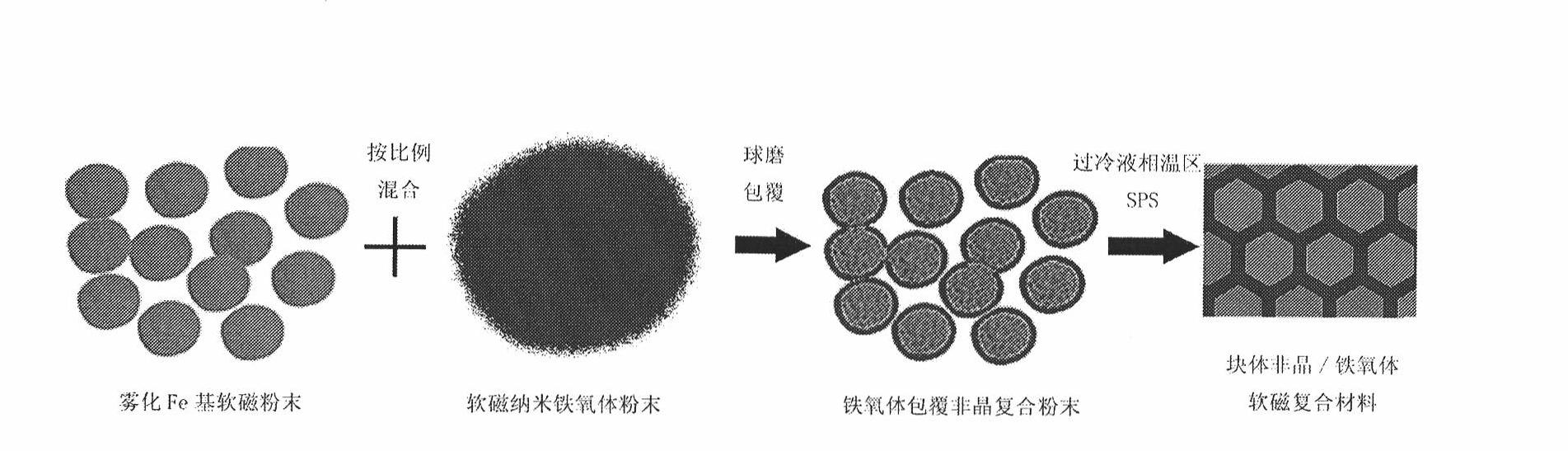

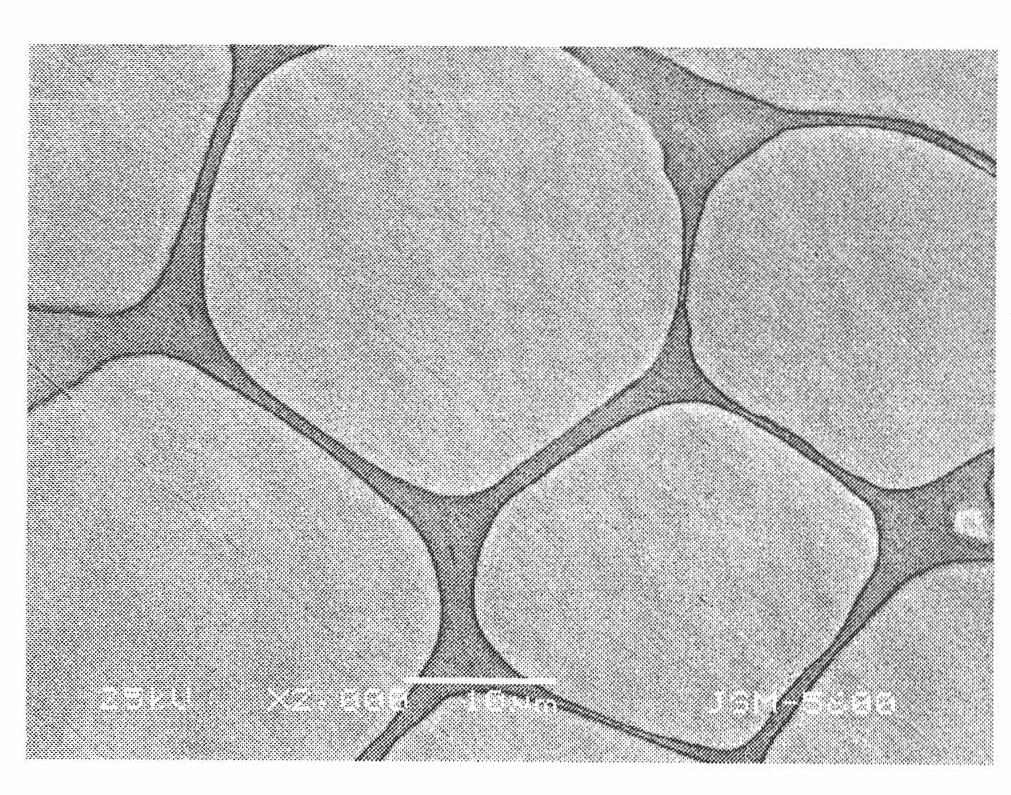

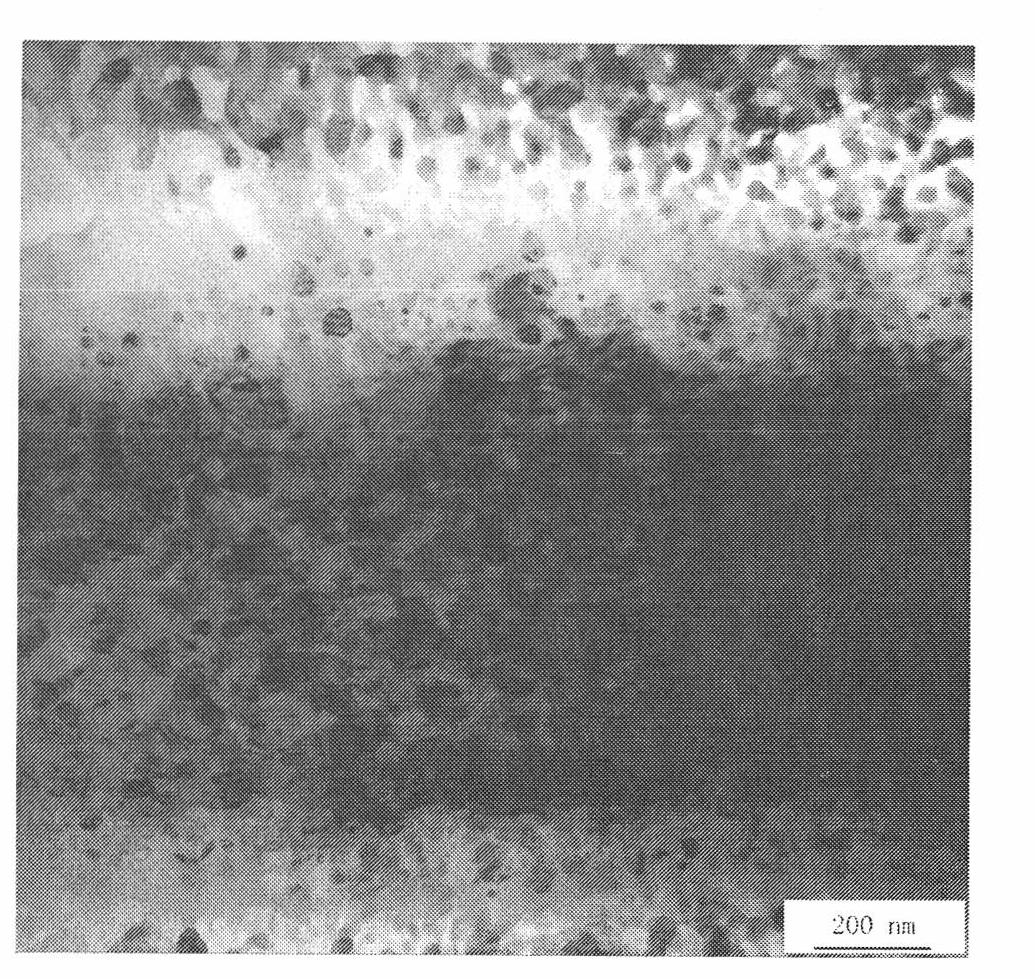

[0032] The bulk amorphous / ferrite soft magnetic composite material of the present invention is an amorphous / ferrite soft magnetic composite material with a three-dimensional honeycomb structure, and the nest wall structure is composed of high resistivity soft magnetic ferrite, and the nest wall ferrite Surround and completely isolate the amorphous alloy soft magnetic phase composed of soft magnetic amorphous alloy particles in the nest, so that the amorphous alloy soft magnetic phases in the nest are insulated from each other, improve eddy current resistance, reduce eddy current loss, and the soft magnetic ferrite phase can block The eddy current passage is coupled with the magnetic field of the amorphous alloy particles, wherein the content of the soft magnetic amorphous alloy particles is 50wt%-99wt%, and the rest is soft ferrite.

[0033] Concrete preparation steps of the present invention are as follows:

[0034] The choice of material composition mainly considers the cost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com