High-specific-strength high-plasticity refractory high-entropy alloy and preparing method thereof

A high-specific-strength, high-entropy alloy technology, applied in the field of metal materials, can solve problems that cannot meet the needs of practical applications, and achieve the effects of good liquid fluidity, low cost, and high densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

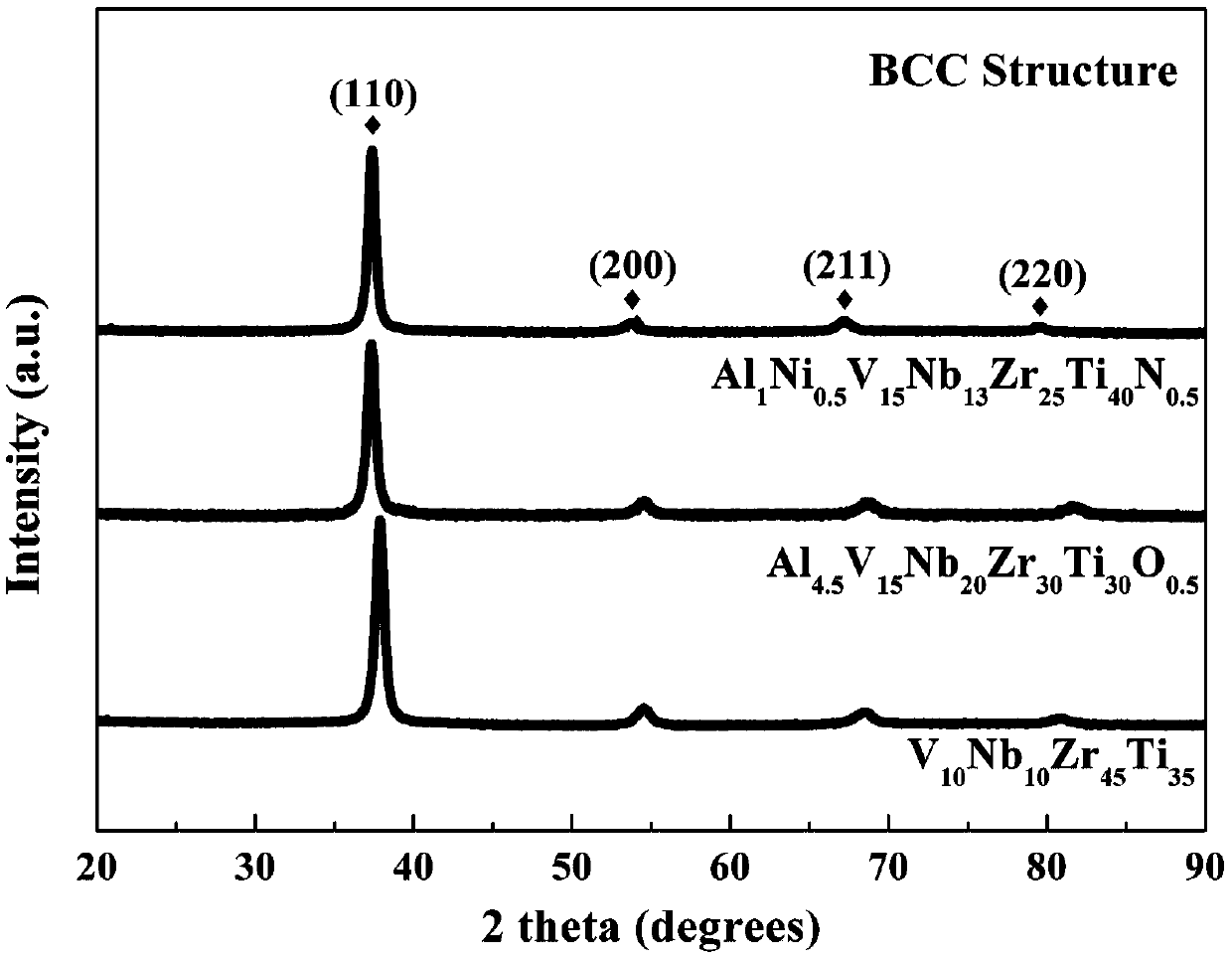

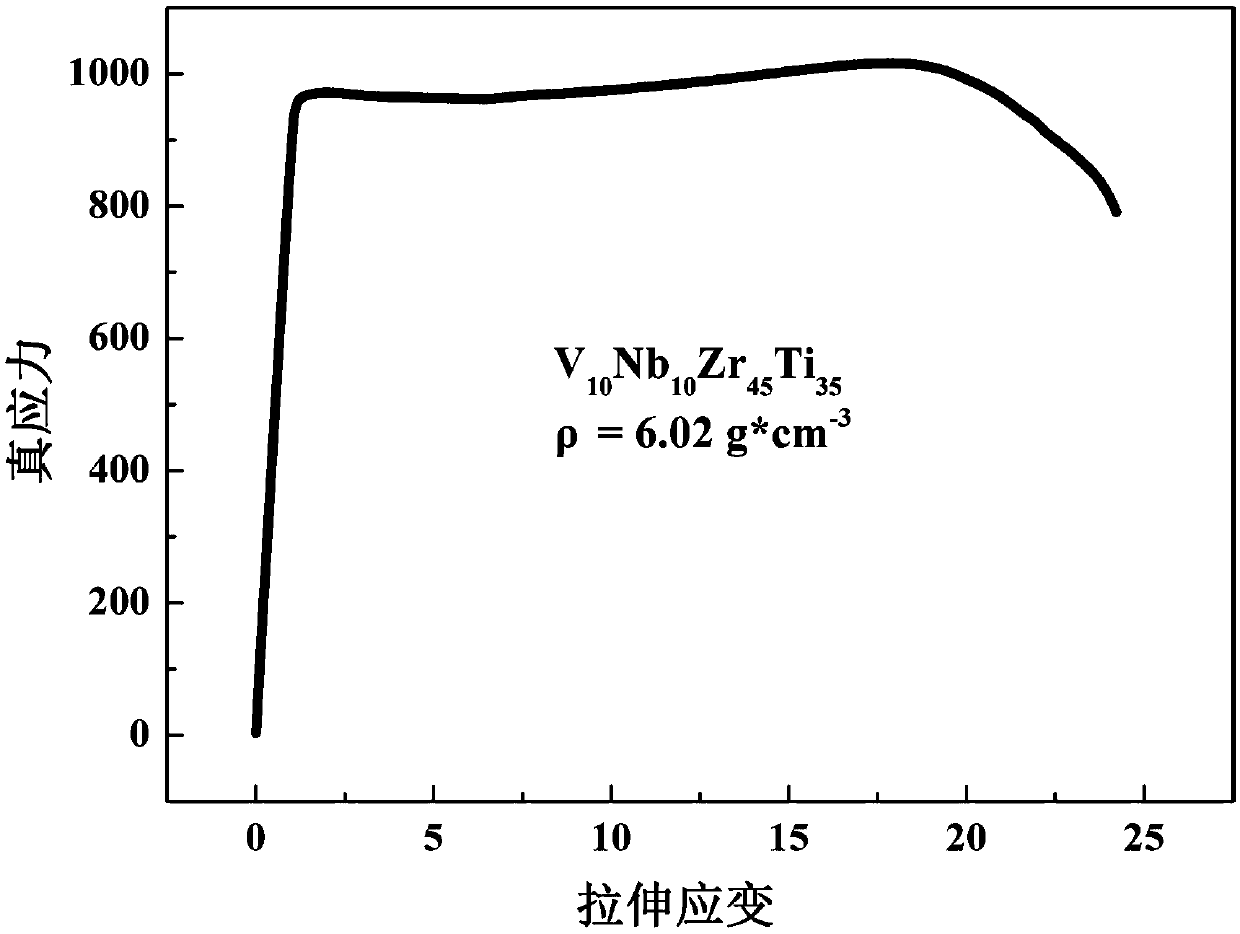

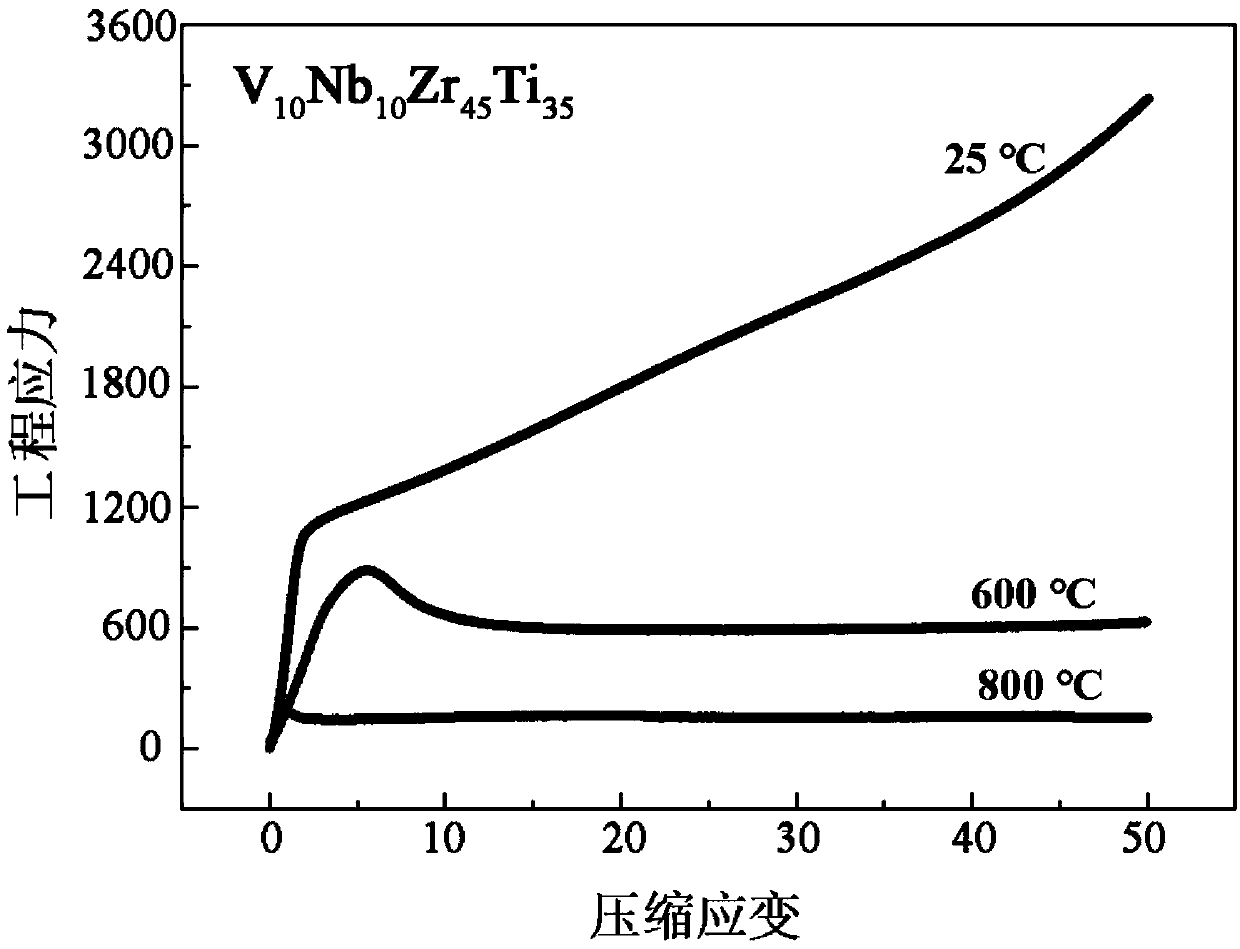

[0036] This embodiment is to prepare a V 10 Nb 10 Zr 45 Ti 35 Refractory high-entropy alloy, the alloy is composed of V, Nb, Zr, Ti four elements. The atomic radius size difference δ is 5.65%, the valence electron concentration VEC is 4.20; the density of the alloy is 99.7%, and the density is 5.99g*cm -3 . from figure 1 It can be seen from the XRD pattern of the alloy that the alloy has a simple BCC crystal structure without precipitation of other phases.

[0037] The metal purity of V, Nb, Zr, Ti is higher than 99.9%;

[0038] The alloy of the present invention can be prepared by various methods, including induction melting, suspension melting, arc melting, mechanical alloying and so on. A kind of preparation method is given as follows now:

[0039] (1) Select four massive pure metals of V, Nb, Zr, and Ti, use 150-mesh sandpaper to remove the surface oxide skin, perform ultrasonic cleaning for 20 minutes, and use an electronic balance to weigh V: 5.65g, Nb: 10.30g in...

Embodiment 2

[0044] This example is to prepare a kind of Al 4.5 V 15 Nb 20 Zr 30 Ti 30 o 0.5 Refractory high-entropy alloy, the alloy is composed of Al, V, Nb, Zr, Ti, O six elements, the atomic radius size difference δ of this alloy is 5.92%, and the valence electron concentration VEC is 4.32; the density of the alloy is 99.7%, the density is 6.09g*cm -3 . from figure 1 It can be seen from the XRD pattern of the alloy that the alloy has a simple BCC crystal structure without precipitation of other phases.

[0045] The V, Nb, Zr, Ti, Al, ZrO 2 Purity higher than 99.9%;

[0046] The alloy of the present invention can be prepared by various methods, including induction melting, suspension melting, arc melting, mechanical alloying and so on. A kind of preparation method is given as follows now:

[0047] (1) Select V, Nb, Zr, Ti, Al four bulk pure metals and bulk ZrO 2 , use 150-grit sandpaper to remove its surface scale, then perform ultrasonic cleaning for 20 minutes, use an elec...

Embodiment 3

[0052] This example is to prepare a kind of Al 1 Ni 0.5 V 15 Nb 13 Zr 25 Ti 40 N 0.5 Refractory high-entropy alloy, the alloy is composed of seven elements: Al, Ni, V, Nb, Zr, Ti, and N. The atomic radius size difference δ is 6.02%, and the valence electron concentration VEC is 4.32;. The density of the alloy is 99.8%, and the density is 6.34g*cm -3 . from figure 1 It can be seen from the XRD pattern that the alloy is composed of BCC simple phase structure.

[0053] The alloy of the present invention can be prepared by various methods, including induction melting, suspension melting, arc melting, mechanical alloying and so on. A kind of preparation method is given as follows now:

[0054] (1) Select Al, Ni, V, Nb, Zr, Ti six block pure metals and block TiN, use 150 mesh sandpaper to remove the surface oxide skin, and then perform ultrasonic cleaning for 20 minutes. Al: 0.35g, Ni: 0.38g, V: 9.82g, Nb: 15.51g, Zr: 29.28g, Ti: 24.28g, : 0.40g were sequentially weighed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Compressive yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com