Environmentally-friendly denitration catalyst and preparation method thereof

A denitration catalyst and environment-friendly technology, applied in the field of environment-friendly denitration catalyst and its preparation, can solve the problems restricting the application of manganese oxide catalyst, and achieve good anti-SO2 poisoning and environment-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

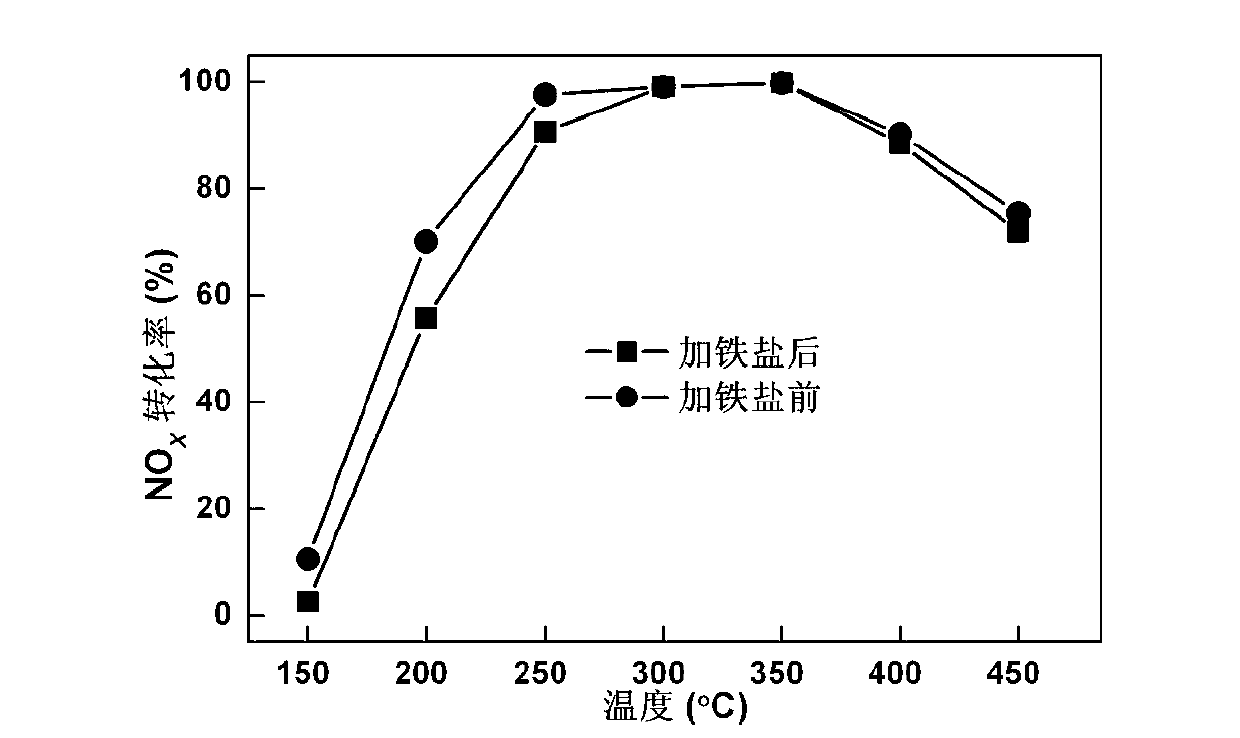

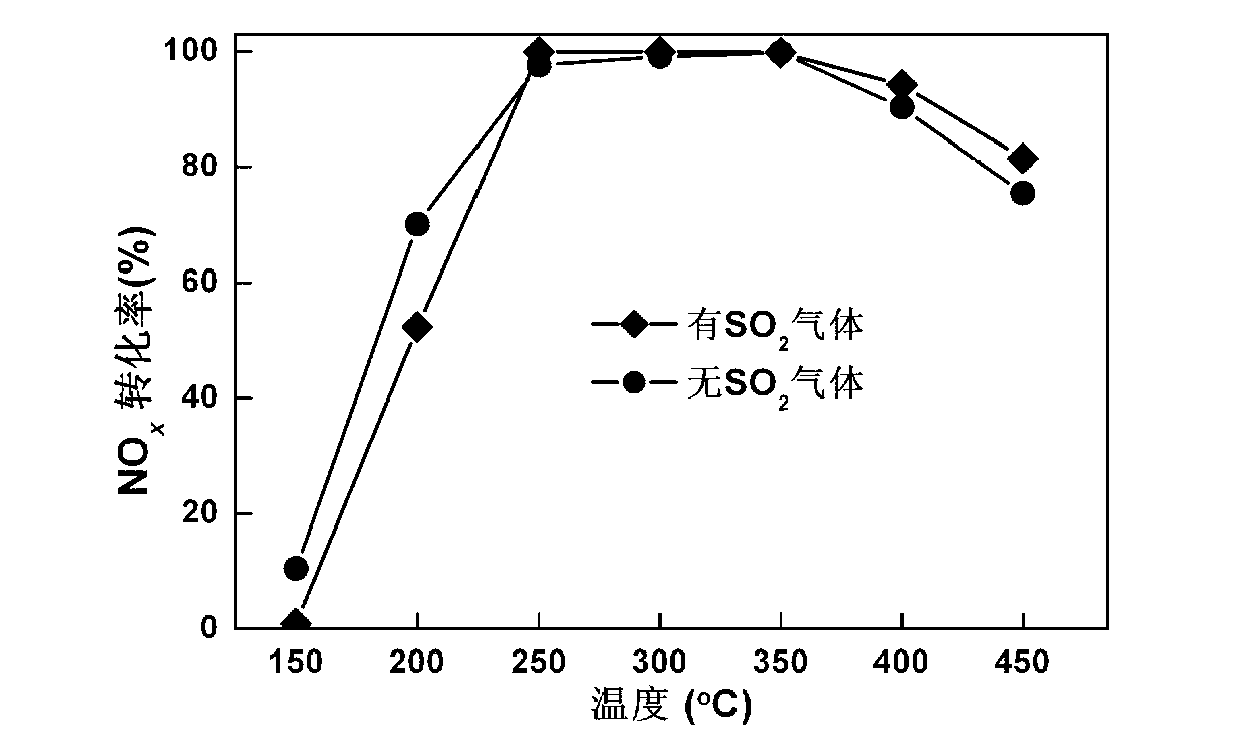

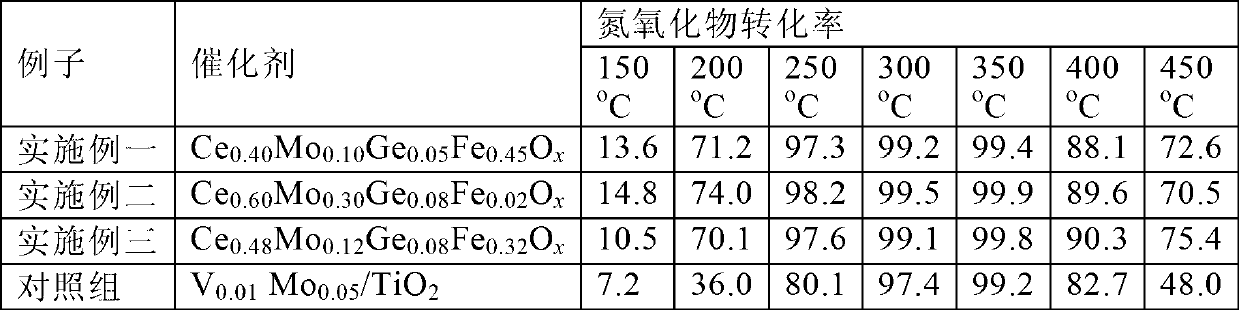

Embodiment 1

[0024] An environment-friendly denitration catalyst, the ratio of raw material components is:

[0025] Cerium nitrate with a content of 40% of the molar percentage of the catalyst, ammonium molybdate with a content of 10% of the molar percentage of the catalyst, germanium oxide with a content of 5% of the molar percentage of the catalyst, and a molar percentage of the catalyst 45% of ferric nitrate.

[0026] The catalyst preparation method comprises the following steps:

[0027] Step 1. Dissolving cerium nitrate and ammonium molybdate in water with 50-120 times the molar amount at room temperature, adding 1 / 10 molar amount of oxalic acid as a cosolvent, and stirring to form a transparent solution. Then dissolve the germanium oxide and ferric nitrate in water with 50 times the molar amount at room temperature, stir evenly, and pour into the above solution.

[0028] Step 2: Dissolve ammonium carbonate in water to prepare a 1mol / L ammonium carbonate solution, then add it dropwi...

Embodiment 2

[0034] An environment-friendly denitrification catalyst, the ratio of raw material components is:

[0035] Cerium nitrate with a content of 60% of the molar percentage of the catalyst, ammonium molybdate with a content of 30% of the molar percentage of the catalyst, germanium oxide with a content of 8% of the molar percentage of the catalyst, and a molar percentage of the catalyst 2% ferric nitrate.

[0036] A preparation method of an environment-friendly denitration catalyst, comprising the following steps:

[0037] Step 1. Dissolving cerium nitrate and ammonium molybdate in water with 50-120 times the molar amount at room temperature, adding 1 / 10 molar amount of oxalic acid as a cosolvent, and stirring to form a transparent solution. Then dissolve the germanium oxide and ferric nitrate in water with 100 times the molar amount at room temperature, stir evenly, and then pour into the above solution.

[0038] Step 2: Dissolve ammonium carbonate in water to prepare a 1mol / L am...

Embodiment 3

[0044] An environment-friendly denitrification catalyst, the ratio of raw material components is:

[0045] Cerium nitrate with a content of 48% of the molar percentage of the catalyst, ammonium molybdate with a content of 12% of the molar percentage of the catalyst, germanium oxide with a content of 8% of the molar percentage of the catalyst, and a molar percentage of the catalyst 32% of ferric nitrate.

[0046] A preparation method of an environment-friendly denitration catalyst, comprising the following steps:

[0047] Step 1. Dissolving cerium nitrate and ammonium molybdate in water with 50-120 times the molar amount at room temperature, adding 1 / 10 molar amount of oxalic acid as a cosolvent, and stirring to form a transparent solution. Then dissolve the germanium oxide and ferric nitrate in water with 100 times the molar amount at room temperature, stir evenly, and then pour into the above solution.

[0048] Step 2: Dissolve ammonium carbonate in water to prepare a 1mol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com