Screening method of oil soluble graphene

A screening method and graphene technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problem that graphite is difficult to exert lubricating performance, and achieve the effect of simple method and good dispersion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Use the following methods to screen oil-soluble graphene

[0021] Mix graphene, base oil and dispersant into a uniform solution, then place the solution in a wall breaking machine for processing at a speed of 25,000 rpm or more for 5 minutes, and then process the processed solution at a centrifugal speed of 60,000 to 80,000 Centrifuge for 15 min under the condition of rpm, remove the sediment and collect the supernatant suspension. In the present embodiment, the base oil uses mineral base oil, and what the dispersant uses is stearic acid, and the consumption accounts for 2.3wt% of the base oil; the graphene uses 5-layer graphene, and the graphene addition accounts for 10wt% of the base oil.

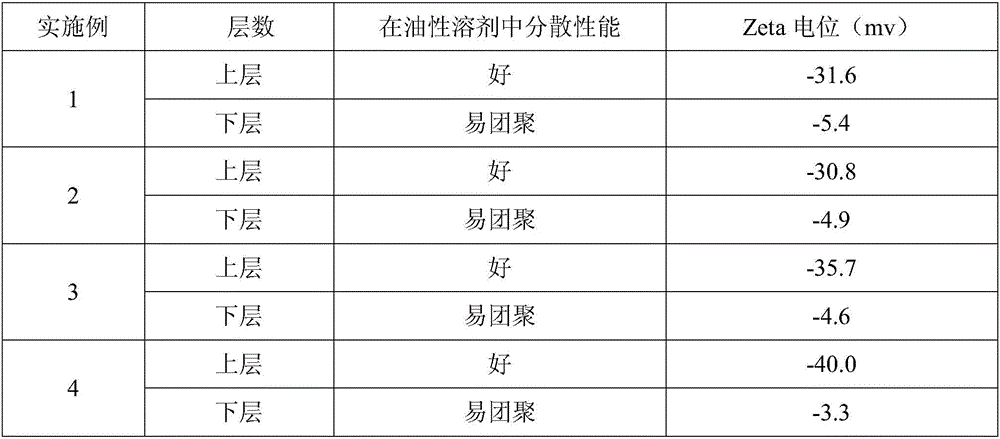

[0022] The state diagram after centrifugation is as follows figure 1 , where 1 represents the graphene floating above, and 2 represents the sinking graphene, by figure 1 It can be seen that the solution presents two states after centrifugation, about 70% of the graphene settles a...

Embodiment 2

[0024] Use the following methods to screen oil-soluble graphene

[0025] Mix graphene, base oil and dispersant into a uniform solution, then place the solution in a wall breaking machine for processing at a speed of 28,000 rpm or more for 8 minutes, and then process the processed solution at a centrifugal speed of 60,000 to 80,000 Centrifuge for 20 min under the condition of rpm, remove the sediment and collect the supernatant suspension. In this embodiment, synthetic base oil is used as the base oil, sodium dodecylbenzenesulfonate is used as the dispersant, and the amount accounts for 2.5 wt% of the base oil, and 3-layer graphene is used for graphene, and the amount accounts for 15% of the base oil .

[0026] The state diagram after centrifugation is as follows figure 1 , where 1 represents the graphene floating above, and 2 represents the sinking graphene, by figure 1 It can be seen that the solution presents two states after centrifugation, about 65% of the graphene sett...

Embodiment 3

[0028] Use the following methods to screen oil-soluble graphene

[0029] Mix graphene, base oil and dispersant into a uniform solution, then place the solution in a wall breaking machine for processing at a speed of 30,000 rpm or more for 6 minutes, and then process the processed solution at a centrifugal speed of 60,000 to 80,000 Centrifuge for 18 min under the condition of rpm, remove the sediment and collect the supernatant suspension. In this embodiment, vegetable base oil is used as the base oil, fatty acid glyceride is used as the dispersant, and the consumption accounts for 3.0 wt% of the total solution, and bilayer graphene is used for graphene, and the consumption accounts for 20% of the base oil.

[0030] The state diagram after centrifugation is as follows figure 1 , where 1 represents the graphene floating above, and 2 represents the sinking graphene, by figure 1 It can be seen that the solution presents two states after centrifugation, about 70% of the graphene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com