Construction method of slant-well pulling into main tunnel for three-line long-span tunnel

A construction method, the technology of the main tunnel, which is applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems of large gaps in section sizes between inclined shafts and main lines, and increased construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

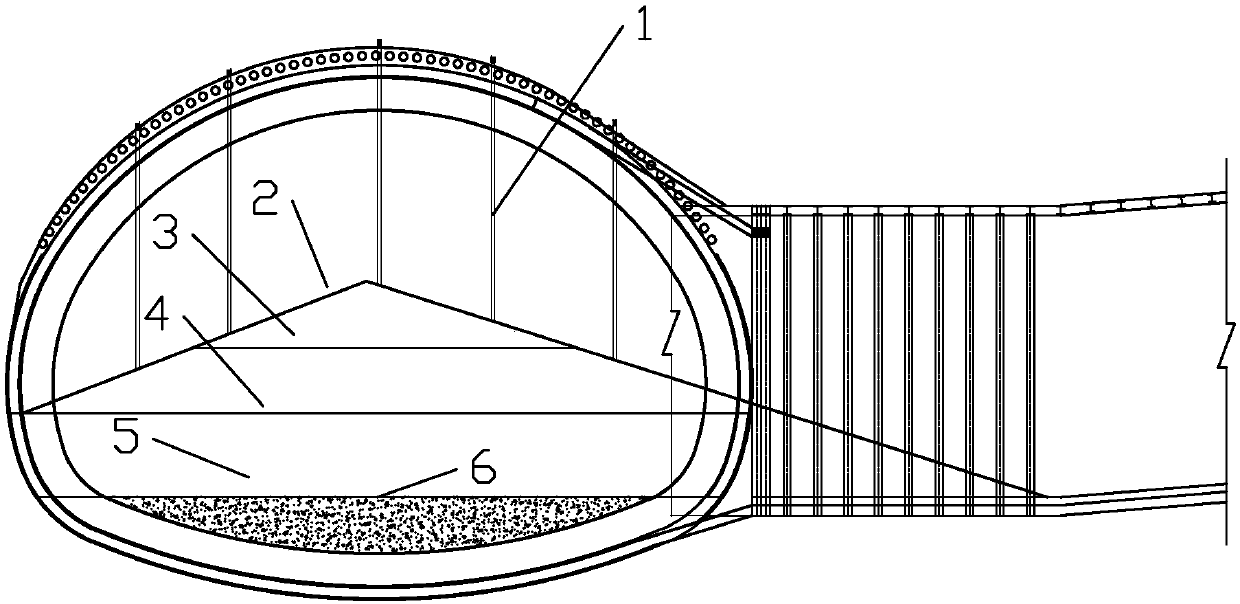

[0023] Such as figure 1 As shown, one of the embodiments provided by the present invention, the construction method of the inclined shaft of the three-line long-span tunnel into the main tunnel, comprises the following steps:

[0024] The first step: Excavate the inclined shaft to the junction of the main tunnel, set up reinforced support at the intersection of the inclined shaft and the main tunnel, set the portal frame at the end of the reinforced support, and install the connecting plate vertically on the portal frame;

[0025] Step 2: Use the pilot tunnel method to raise the roof upwards to enter the main tunnel, excavate the climbing pilot tunnel obliquely upwards to the same elevation as the vault of the main tunnel, and at the same time continue to construct the pilot tunnel horizontally until the left side of the main tunnel, so that the main tunnel The arch has a stable foundation;

[0026] The third step: the installation of the main line arch frame, and the initial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com