Lithium iron phosphate/carbon composite material for power battery, and preparation method and application of lithium iron phosphate/carbon composite material

A carbon composite material, lithium iron phosphate technology, applied in batteries, battery electrodes, secondary batteries, etc., can solve problems such as poor rate performance and high temperature cycle performance, and achieve the effect of alleviating side reactions and improving high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

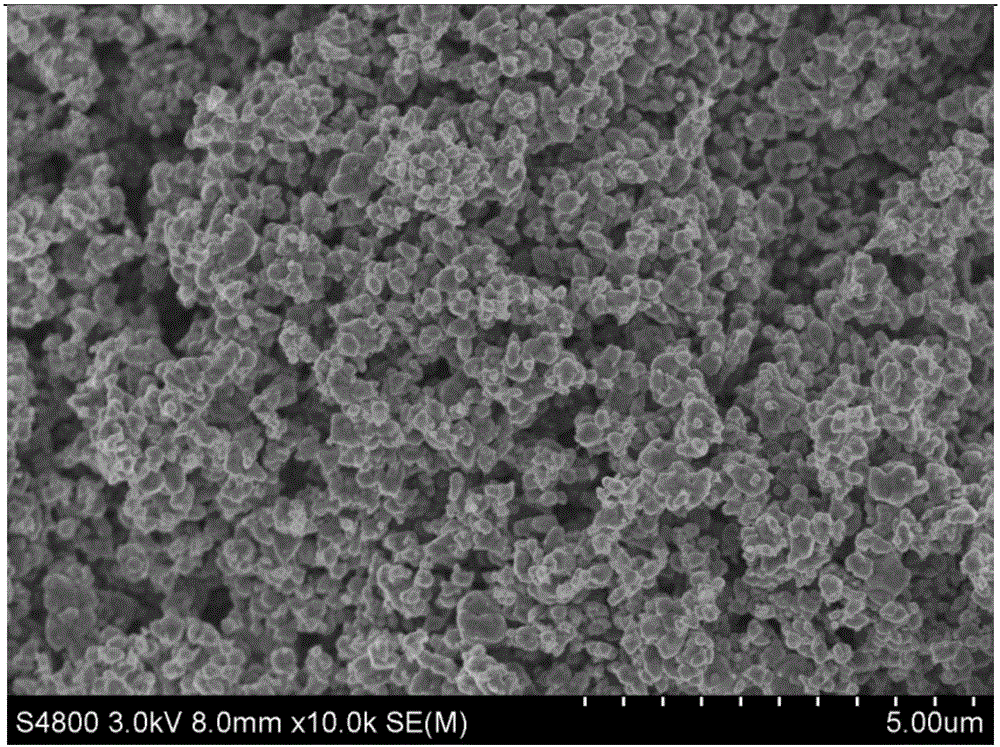

Image

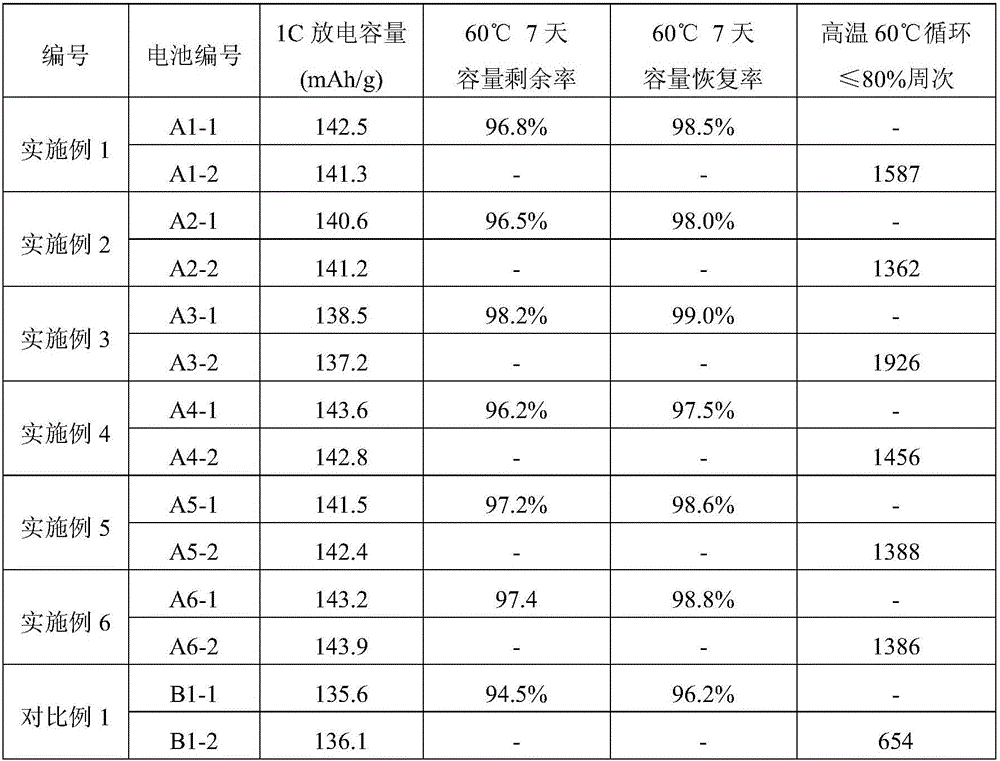

Examples

Embodiment 1

[0046] Mix lithium carbonate, iron phosphate, and titanium dioxide according to the molar ratio of 1.05:1:0.01, then Li:Fe:P:Ti=1.05:1:1:0.01, and add water to 40% of the total mass of the mixed material for ball milling , take out the slurry after 3 hours, dry it with a closed spray dryer, set the temperature of the air inlet to 250°C, and set the temperature of the air outlet to 90°C to obtain material A, crush the material A, control D50 to 5±1.0μm, and obtain the material B. Raise the temperature of material B at 2°C / min in an atmosphere of Ar gas, and feed methane gas at a flow rate of 5L / min. After the temperature rises to 600°C, it is kept for 15 hours to obtain material C, which is pulverized and controlled D50 is 2.0±1.0μm, get material D, put material D in N 2 In an atmosphere of gas, the temperature was raised at 10°C / min, and methane gas was introduced at a flow rate of 0.5L / min. After the temperature was raised to 750°C, it was kept for 8 hours to obtain a lithium...

Embodiment 2

[0048] Lithium hydroxide, ferrous oxalate, and phosphoric acid are mixed according to the molar ratio of 0.95:1:0.95, then Li:Fe:P=0.95:1:0.95, and 40% of the total mass of the material obtained by mixing is added with acetone for ball milling, After 3 hours, take out the slurry, dry it with a closed spray dryer, set the air inlet temperature at 220°C, and set the air outlet temperature at 70°C to obtain material A, crush material A, control D50 to 7±1.0μm, and obtain material B , put material B in N 2 Raise the temperature at 20°C / min in an air atmosphere, and feed ethylene gas at a flow rate of 0.5L / min. After the temperature rises to 700°C, keep it warm for 10 hours to obtain material C, which is pulverized, and the D50 is controlled to be 5.0±1.0μm , to get material D, put material D in N 2 In an atmosphere of gas, the temperature was raised at 5°C / min, and methane gas was introduced at a flow rate of 2L / min. After the temperature was raised to 800°C, it was kept for 3 ho...

Embodiment 3

[0050] Lithium dihydrogen phosphate, ferric oxide, and manganese acetate are mixed according to the molar ratio of 1:0.95:0.05, then Li:Fe:P:Mn=1:0.95:1:0.05, and the total mass of the material obtained by mixing Add 50% ethanol for ball milling, take out the slurry after 5 hours, and dry it with a closed spray dryer, set the air inlet temperature to 220°C, and the air outlet temperature to 70°C to obtain material A, and crush material A to control D50 to 4 ±1.0μm, to obtain material B, raise the temperature of material B at 10°C / min in the atmosphere of Ar gas, and pass in propane gas according to the flow rate of 8L / min, the temperature rises to 800°C and keep it for 3h, and obtain material C, put The material C is pulverized, and the D50 is controlled to be 2.0±1.0 μm to obtain the material D. The temperature of the material D is raised at 10°C / min under the atmosphere of Ar gas, and cyclopropane gas is passed in according to the flow rate of 10L / min, and the temperature ris...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com