Automatic spinning-necking equipment

An automatic and equipment technology, applied in the field of mechanical processing, can solve the problems of poor coating integrity, low production efficiency, and many processing procedures, and achieve the effect of complete coating, high production efficiency and good coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing:

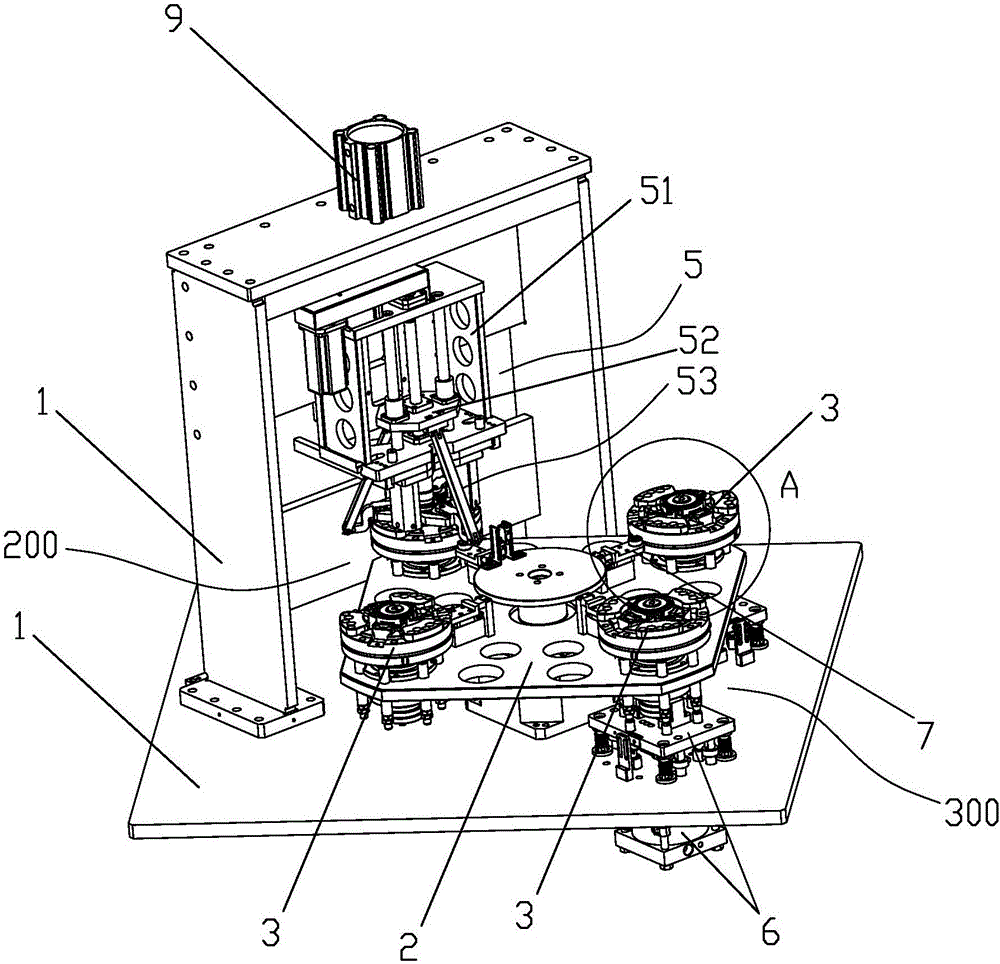

[0044] like Figure 1 to Figure 12 As shown, an automatic spinning and closing equipment includes a frame 1, and the frame 1 is provided with a rotating disk 2, and the rotating disk 2 is provided with a plurality of workpieces for clamping the workpiece 100 and can be rotated. The disk 2 is transported to the clamp assembly 3 of the spinning station 200 and the non-spinning station 300, and the frame 1 is provided with a clamp assembly 3 capable of engaging with the spinning station 200 to drive the clamp assembly 3 and the clamp assembly. The power assembly 4 that rotates the workpiece 100 in the assembly 3, the spinning assembly 5 for spinning and closing the workpiece 100 is provided above the spinning station 200, and the spinning assembly 5 includes a Lifting frame 51, the lifting frame 51 is provided with a lifting plate 52 that can be raised and lowered relative to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com