Automatic dispensing and glue point detection device and dispensing and detection technology thereof

A technology of automatic glue dispensing and detection device, which is applied to devices and coatings that apply liquid to the surface, which can solve problems such as inability to simultaneously and guarantee glue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

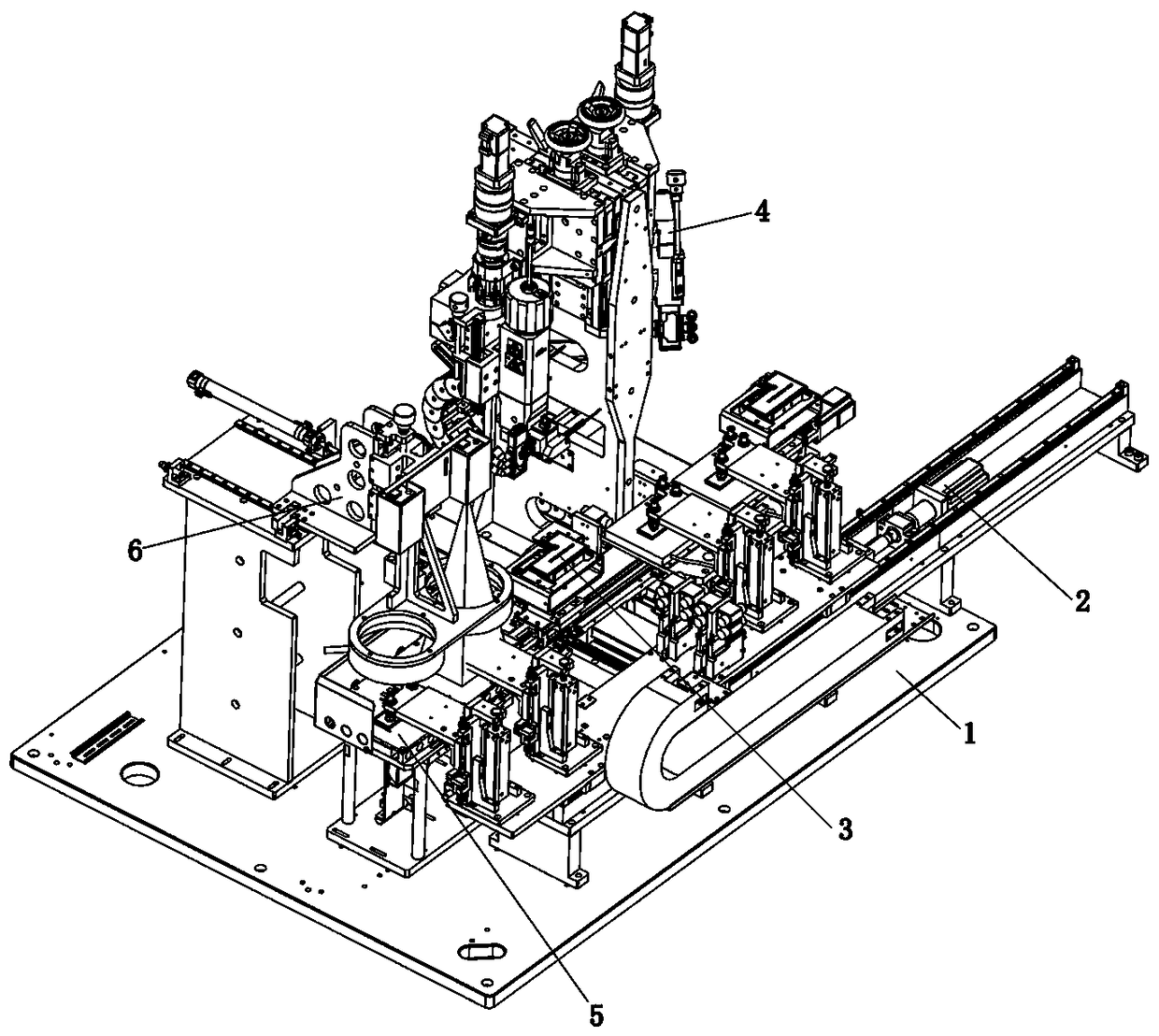

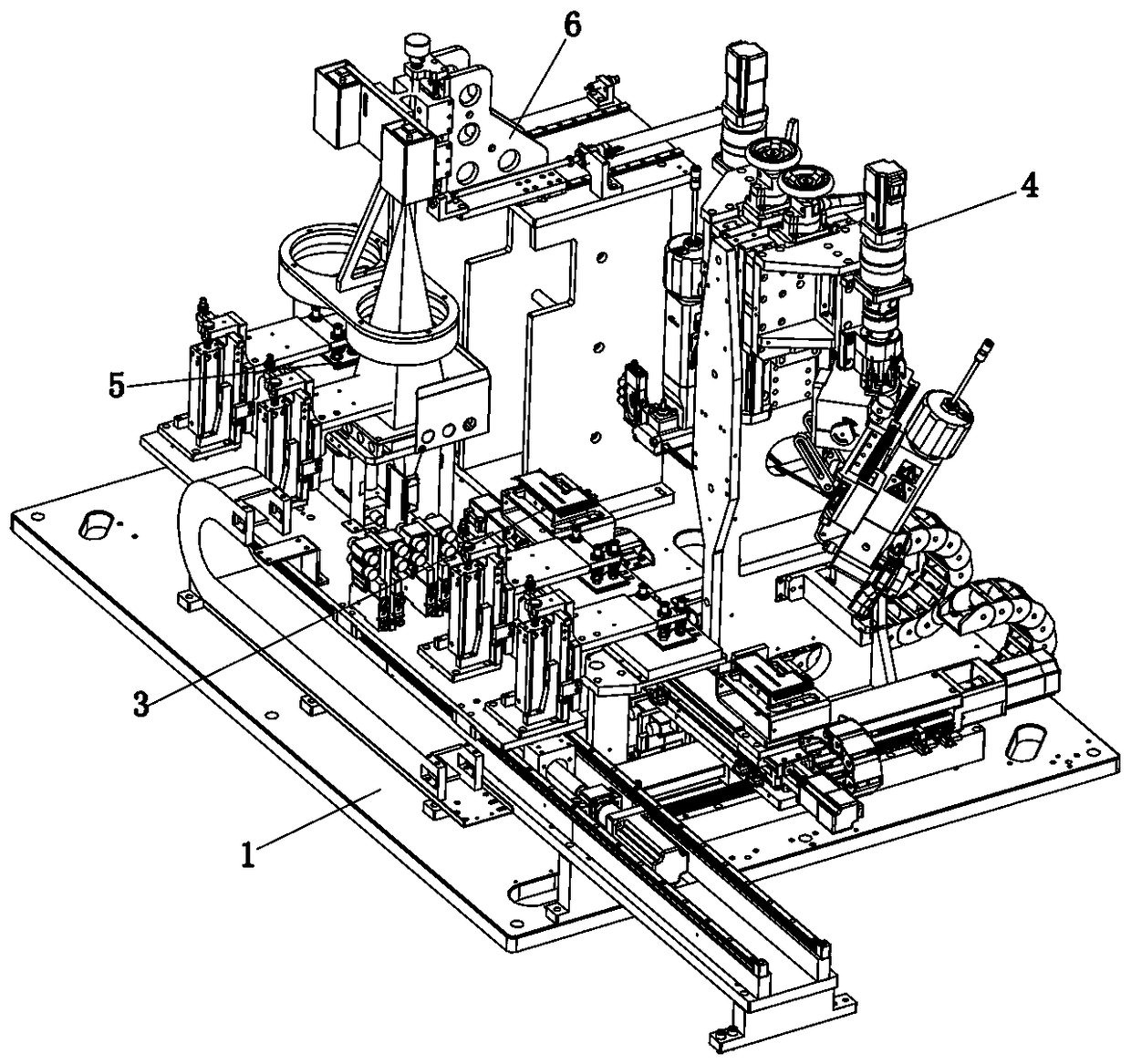

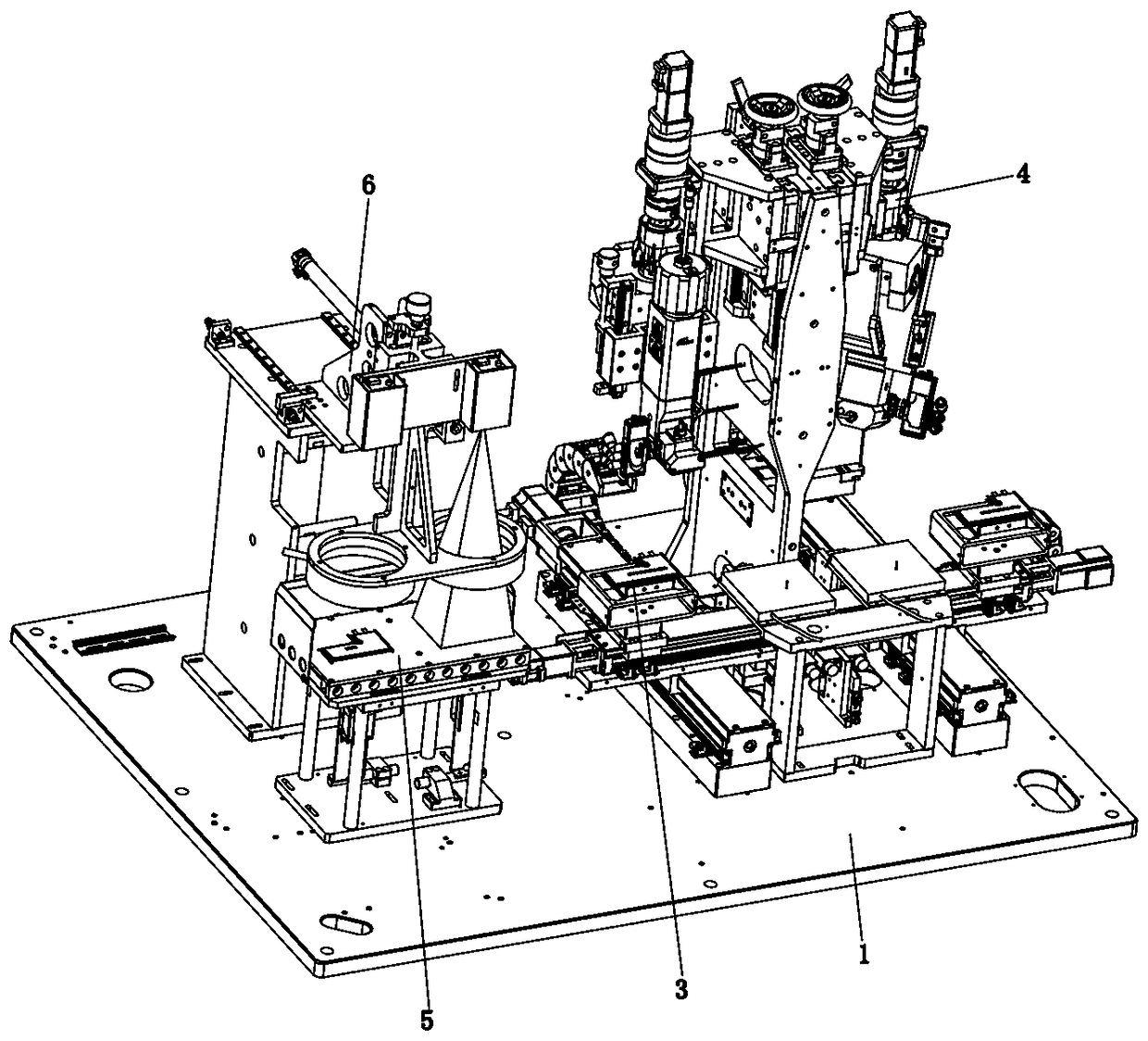

[0063] Embodiment 1: as Figure 1 to Figure 21 As shown, the technical scheme adopted by the present invention is as follows: an automatic glue dispensing and glue point detection device, including a machine 1, a transfer mechanism 2, a glue dispensing platform 3, a glue dispensing mechanism 4, a detection platform 5 and a CCD mechanism 6, Wherein, the above-mentioned dispensing platform 3 and the detection platform 5 are arranged at intervals on the machine platform 1; the above-mentioned transfer mechanism 2 is arranged on one side of the dispensing platform 3 and the detection platform 5, and the transfer mechanism 2 includes at least two sets of transfer components 27 , and each transfer assembly 27 moves linearly synchronously, and respectively transfers the cell 0 to be dispensed and the cell 0 after dispensing to the dispensing platform 3 and the detection platform 5 synchronously; the above-mentioned dispensing mechanism 4 and CCD mechanism 6 They are respectively inst...

Embodiment 2

[0094] Embodiment 2: as Figure 1 to Figure 10 , Figure 15 to Figure 20 As shown, it is Embodiment 2 of the present invention. The two sets of dispensing mechanisms of this embodiment can adopt two sets of straight dispensing assembly structures, that is, the dispensing nozzles of the dispensing guns are all vertically arranged, and the angle of the dispensing guns is fixed. , cannot be adjusted according to actual dispensing requirements, and the application range is narrow.

Embodiment 3

[0095] Embodiment 3: as Figure 1 to Figure 9 , Figure 11 to Figure 21 As shown, it is Embodiment 3 of the present invention. The two sets of dispensing mechanisms of this embodiment can adopt the structure of two sets of oblique dispensing components, and the angle of the dispensing gun can be adjusted according to the actual dispensing situation, and through the angle adjustment component Make adjustments to ensure that the horizontal position of the dispensing nozzle of the dispensing gun remains unchanged through the auxiliary needle; Figure 14 As shown, when the strip chute of the second connecting seat of the oblique dispensing assembly slides to the top, the dispensing nozzle is vertically arranged, which is equivalent to a straight dispensing assembly. The application range of this embodiment is wider than that of Embodiment 2. wide and flexible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com