Method for preparing flexible three-dimensional solid electrolyte membrane

A solid electrolyte, three-dimensional technology, applied in the field of lithium-ion batteries, can solve the problems that the ionic conductivity of the polymer electrolyte cannot be effectively improved, and the polymer electrolyte does not have flexibility, etc., to achieve excellent electrochemical stability and flexibility, good flexibility properties, high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] An embodiment of the present invention provides a method for preparing a flexible three-dimensional solid electrolyte membrane, the method comprising the following steps:

[0024] Step 1: adding the nanofibers into the solvent and ultrasonically dispersing to prepare a nanofiber suspension;

[0025] Step 2: adding lithium-ion conductive ceramic particles into the nanofiber suspension and stirring, so that the nano-ceramic particles are evenly distributed in the nanofiber matrix, and freeze-drying to obtain a ceramic particle / nanofiber three-dimensional porous composite scaffold;

[0026] Step 3: adding the lithium salt to the acetonitrile solution of polyethylene oxide and stirring to obtain a lithium salt-polyethylene oxide mixture;

[0027] Step 4: soak the obtained ceramic particle / nanofiber three-dimensional porous composite scaffold in the lithium salt-polyethylene oxide mixture, and obtain ceramic particle / nanofiber-reinforced polyethylene oxide base after drying ...

Embodiment 1

[0037] This embodiment provides a method for preparing a flexible three-dimensional solid electrolyte membrane, the specific steps of which are as follows:

[0038](1) Weigh 0.5g of plant nanofibers into 100mL of ultrapure water, and ultrasonically disperse to prepare a 5mg / mL nanofiber (NF) suspension;

[0039] (2) Weigh 9.5g garnet-type Li 6.4 La 3 Zr 2 Al 0.2 o 12 Salt (LLZO) was added to the above-mentioned nanofiber suspension, stirred at high speed, so that the nano-ceramic particles were evenly distributed in the nano-fiber matrix, and after freeze-drying, a ceramic particle / nanofiber (LLZO / NF) three-dimensional porous composite scaffold was obtained;

[0040] (3) Weigh 0.9g of lithium bis(trifluoromethane)sulfonylimide (LiTFSI) and 2.5g of polyethylene oxide (PEO) into 100g of acetonitrile solution, stir at high speed to make the lithium salt and polyethylene oxide Alkanes were dissolved to obtain a viscous liquid of lithium salt-polyethylene oxide (LiTFSI–PEO); ...

Embodiment 2

[0043] This embodiment provides a method for preparing a flexible three-dimensional solid electrolyte membrane, the specific steps of which are as follows:

[0044] (1) Weigh 1g of plant nanofibers into 100mL of ultrapure water, and ultrasonically disperse to prepare a 10mg / mL nanofiber (NF) suspension;

[0045] (2) Weigh 9.5g garnet-type Li 6.4 La 3 Zr 2 Al 0.2 o 12 Salt (LLZO) was added to the above-mentioned nanofiber suspension, stirred at high speed, so that the nano-ceramic particles were evenly distributed in the nano-fiber matrix, and after freeze-drying, a ceramic particle / nanofiber (LLZO / NF) three-dimensional porous composite scaffold was obtained;

[0046] (3) Weigh 0.9g of lithium bis(trifluoromethane)sulfonylimide (LiTFSI) and 2.5g of polyethylene oxide (PEO) into 100g of acetonitrile solution, stir at high speed to make the lithium salt and polyethylene oxide Alkanes were dissolved to obtain a viscous liquid of lithium salt-polyethylene oxide (LiTFSI–PEO); ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dispersion concentration | aaaaa | aaaaa |

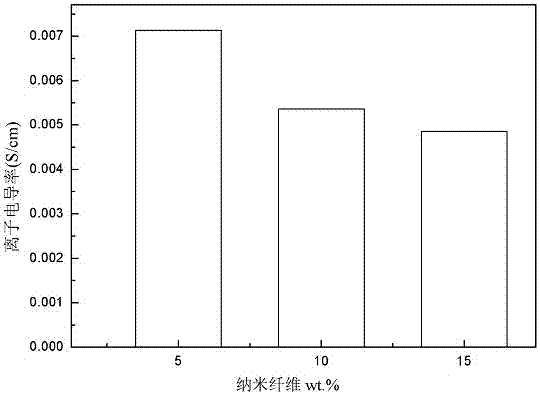

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com