Composite stressed-skin construction for fuselage and technique of preparing the same

A technology for aircraft fuselage and skin, which is applied in the field of composite skin structure and its preparation process, can solve the problems of inability to manufacture large aircraft, high density, heavy weight, etc., and achieves easy implementation of manufacturing process, convenient manufacturing, high weight light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described below in conjunction with accompanying drawing.

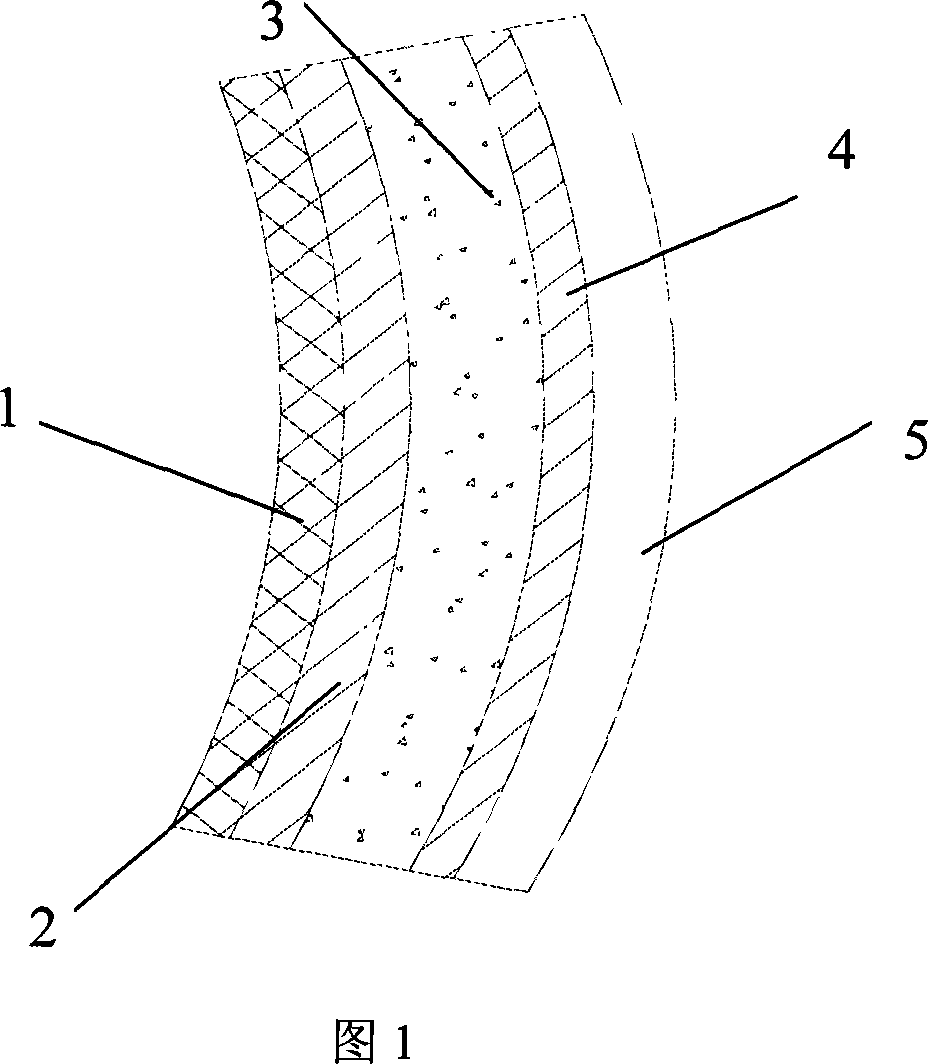

[0021] As shown in Figure 1, the composite skin structure for the aircraft fuselage includes, in turn, an inner wall layer 1, an inner carbon fiber reinforced plastic layer 2, a foam core layer 3, an outer carbon fiber reinforced plastic layer 4 and an outer protective layer 5.

[0022] The inner wall layer 1 is an aramid fiber layer or a glass fiber reinforced resin-rich layer. It can meet the functional requirements of interior decoration, fire prevention, seepage prevention and impact prevention

[0023] The foam core layer 3 is a high-performance structural foam layer selected from polymethacrylimide foam layer or polyetherimide foam layer.

[0024] A certain number of stringers are arranged in the foam core layer. The number of stringers can be determined according to specific requirements. The inner carbon fiber reinforced plastic layer 2, the foam core layer 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com