Patents

Literature

81results about How to "The manufacturing process is easy to implement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

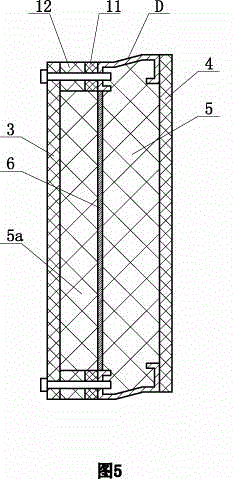

Device and method for high-throughput electrochemical characterization of composite material chip

InactiveCN106769833AThe manufacturing process is easy to implementMeet screening requirementsWeather/light/corrosion resistanceElectrode potentialPower flow

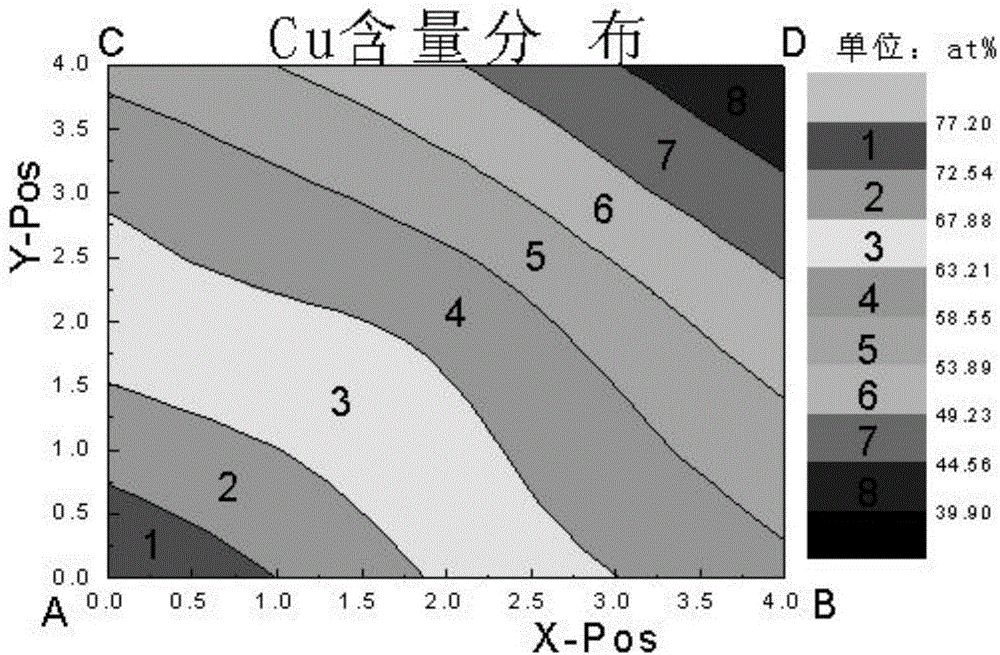

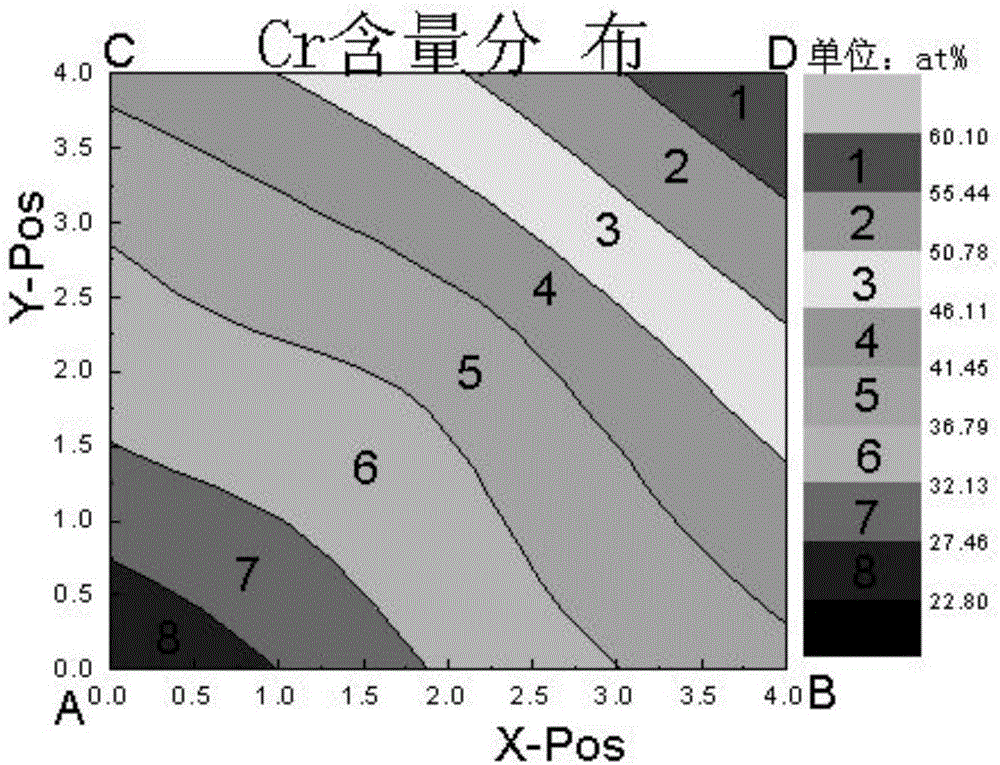

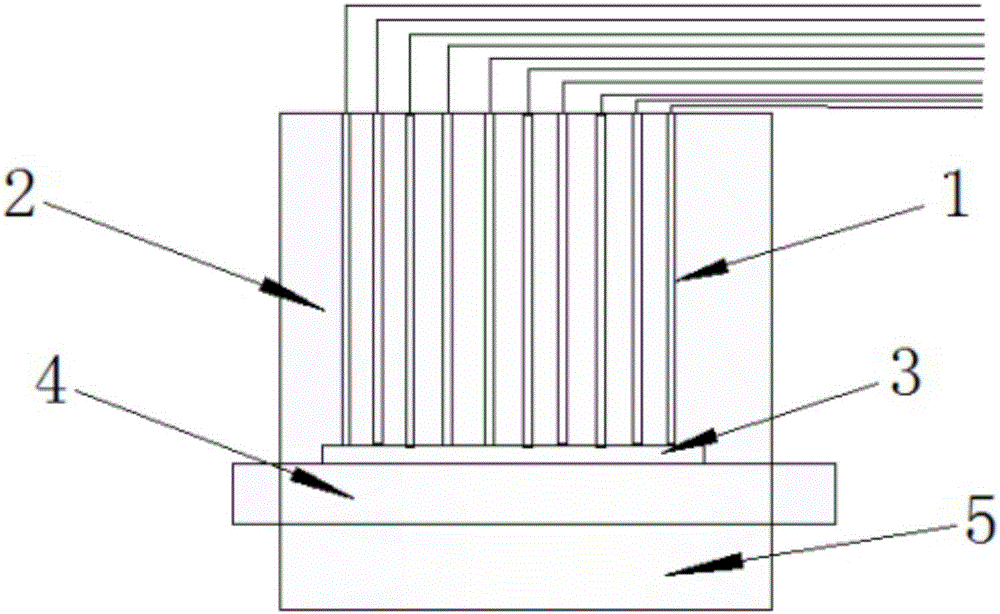

The invention relates to a device and a method for high-throughput electrochemical characterization of a composite material chip. A testing instrument comprises a wire beam electrode, a wire beam electrode current and potential scanner, a film sample with composition gradient distribution and a specific corrosive medium. An electrode potential and current of each probe of the wire beam electrode are obtained by a wire beam electrode measurement method in the wire beam electrode current and potential scanner, so that potential distribution and current distribution in different regions on the surface of the film sample can be compared; finally, local electrochemical parameter information of the surface of the sample to be measured is obtained. The measurement method is simple to operate and can take parallel measurement of the multiple regions at the same time, so that the characterization speed of the electrochemical information can be greatly increased; a quick screening method is provided for corrosion resistance evaluation of a material.

Owner:UNIV OF SCI & TECH BEIJING

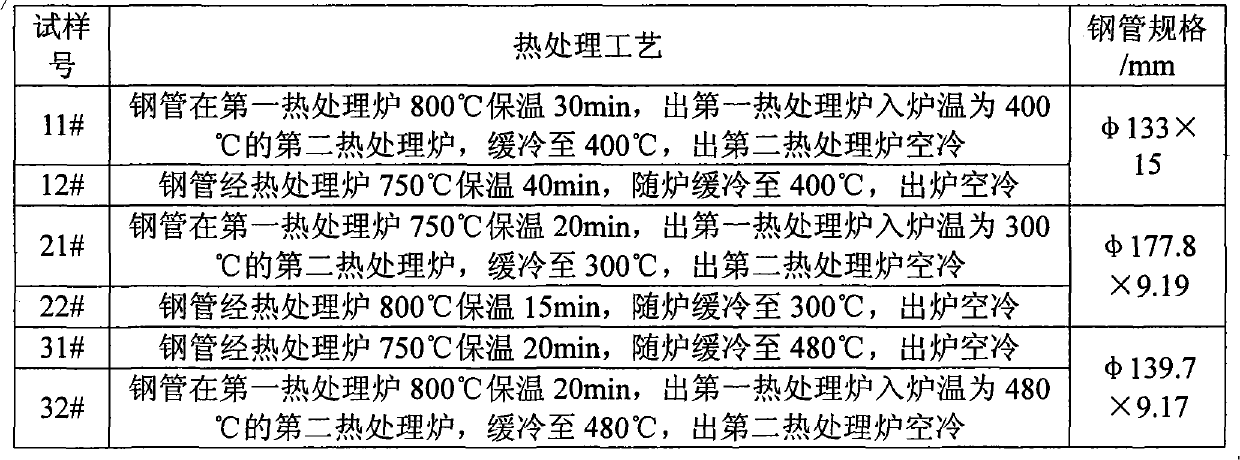

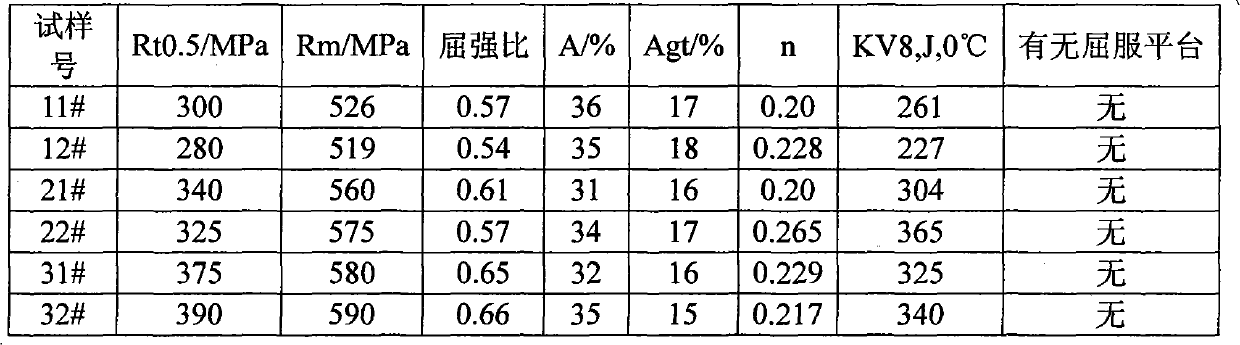

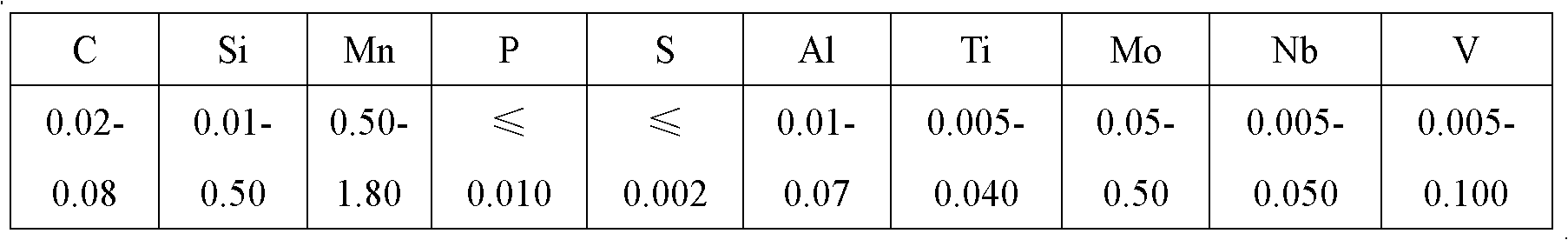

Economical seamless oil well pipe for expansion pipe and manufacturing method thereof

ActiveCN102022086AHigh elongationUniform elongationDrilling rodsManufacturing convertersChemical compositionHeat penetration

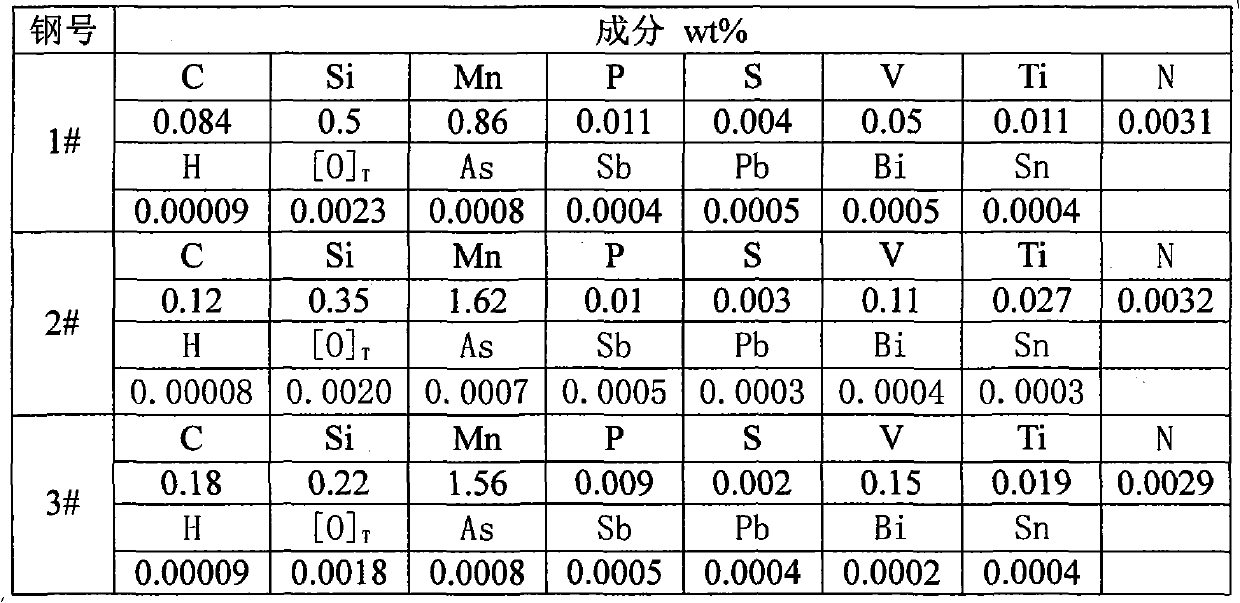

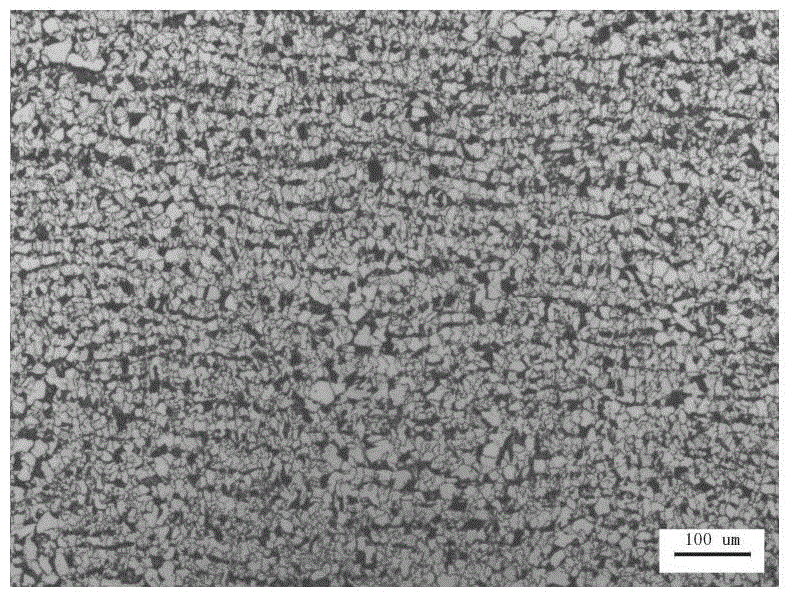

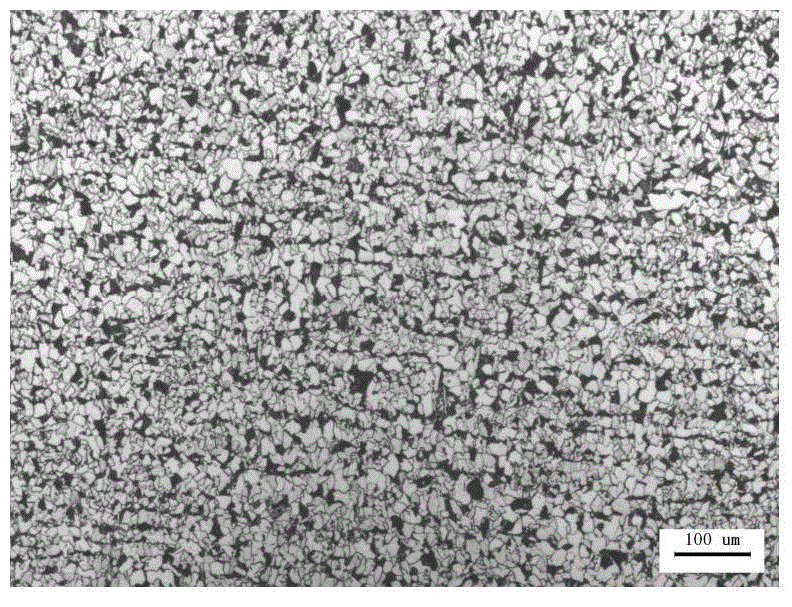

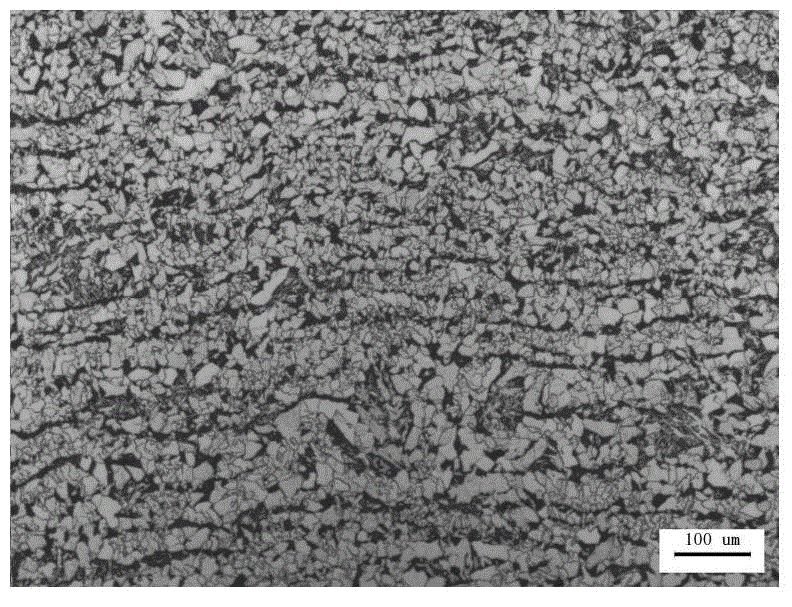

The invention provides an economical seamless oil well pipe for an expansion pipe and a manufacturing method thereof. The oil well pipe comprises the following chemical components in percentage by weight: 0.08 to 0.18 percent of C, 0.2 to 0.5 percent of Si, 0.6 to 1.7 percent of Mn, less than or equal to 0.012 percent of P, less than or equal to 0.005 percent of S, 0.04 to 0.15 percent of V, 0.01to 0.03 percent of Ti and the balance of Fe and inevitable impurities. A heat treatment process in the manufacturing method comprises the following steps of: incompletely quenching a hot-rolled seamless pipe, controlling the temperature of a heating furnace at 750 to 800 DEG C, keeping the temperature of the steel pipe in the range of 30 to 40 DEG C higher than Ac1 and 30 to 40 DEG C lower than Ac3 between the two phase regions of ferrite and austenite, performing calculation at the heat penetration speed of 1mm / min, preserving the heat of the oil well pipes for 10 to 60 min after the hot-rolled oil well pipes with different wall thicknesses reach the temperature of the furnace, and then cooling the oil well pipes at the speed of not higher than 0.2 DEG C per second. In the economical seamless oil well pipe and the manufacturing method thereof, the manufacturability and expandability performance of the steel pipe, the mechanical properties of the expanded steel pipe and the manufacturing cost are taken into account.

Owner:ANGANG STEEL CO LTD

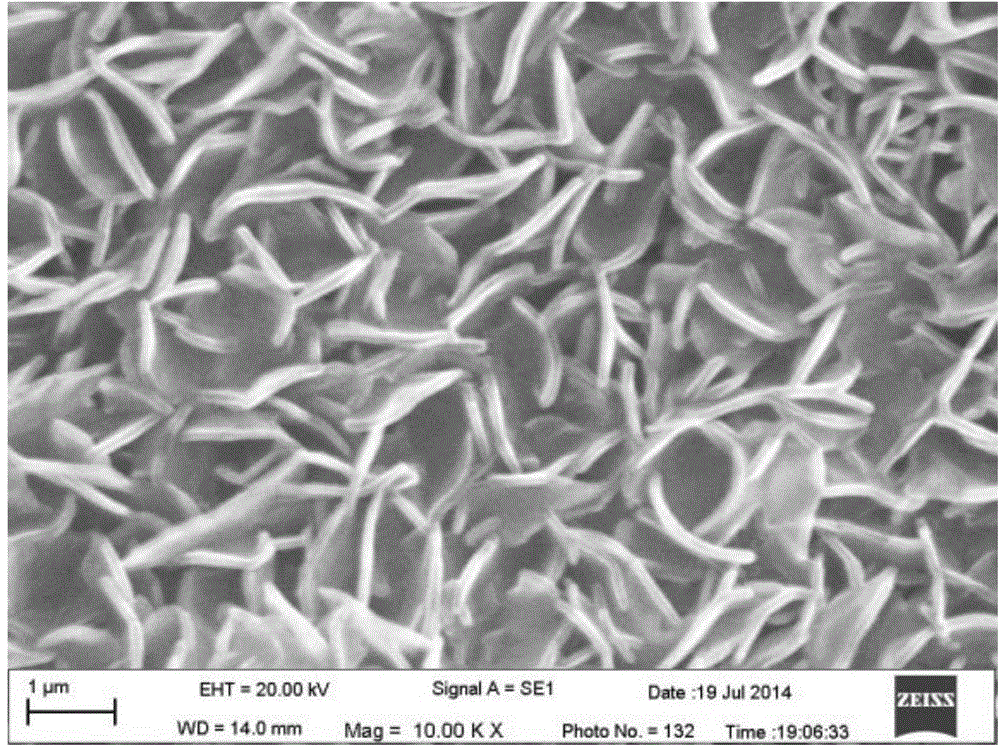

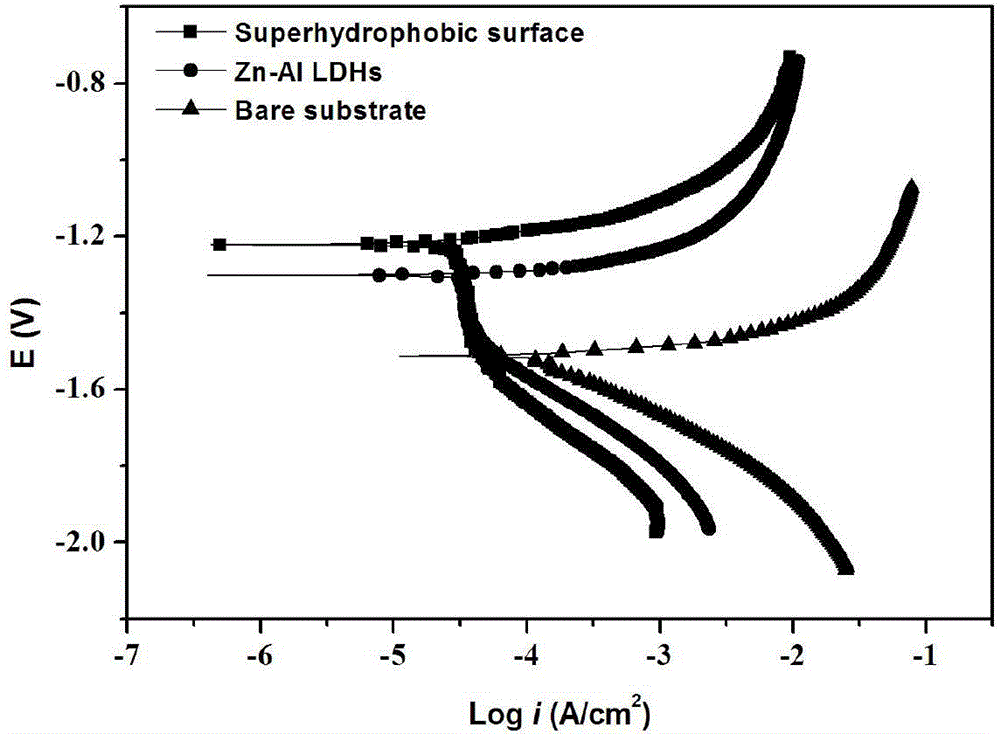

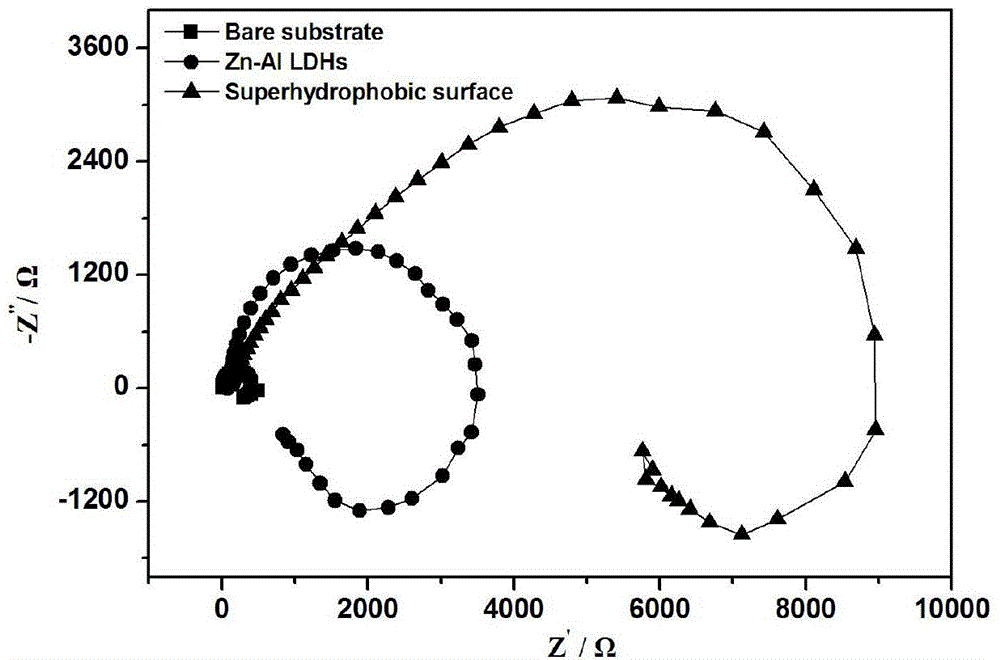

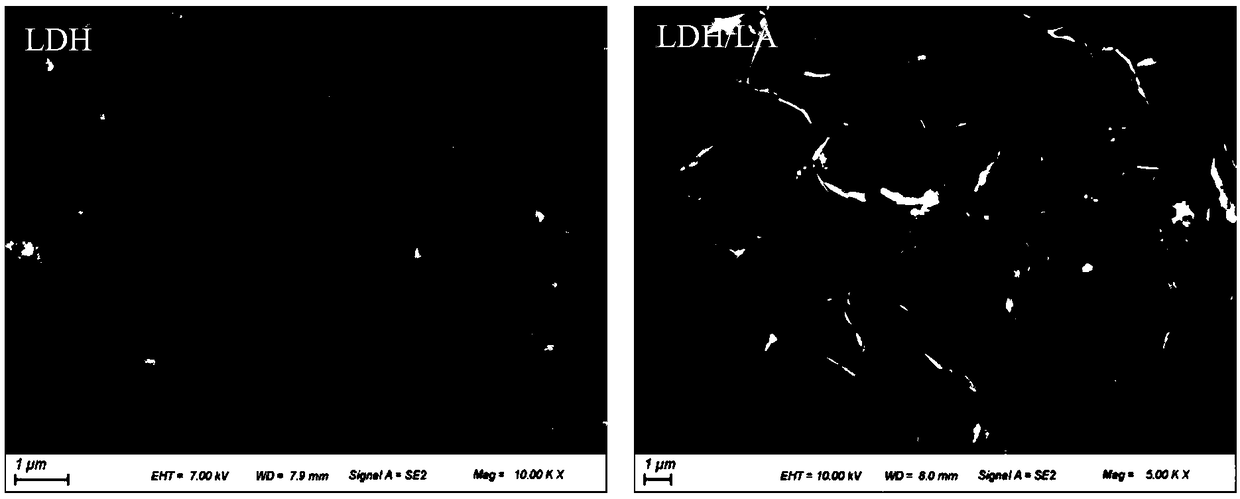

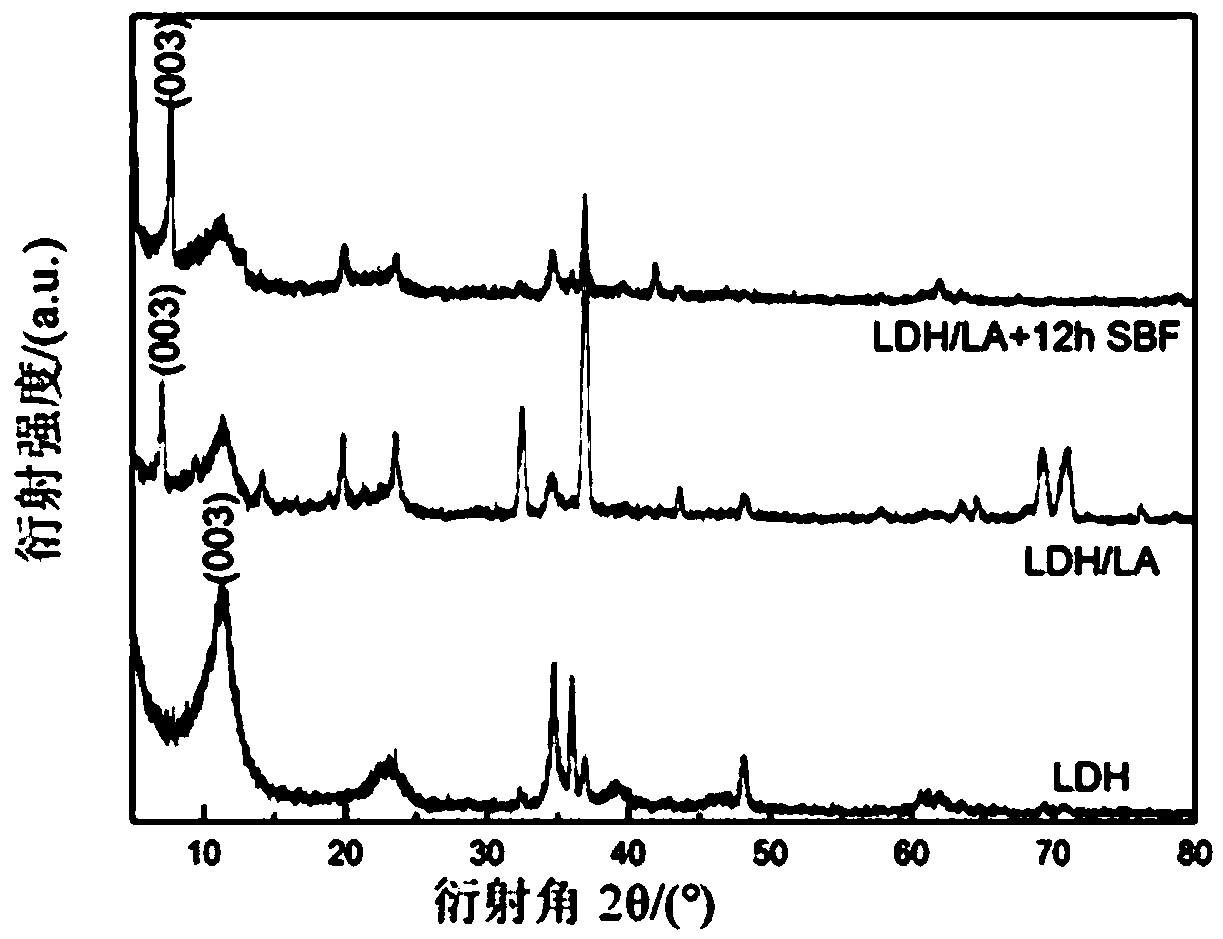

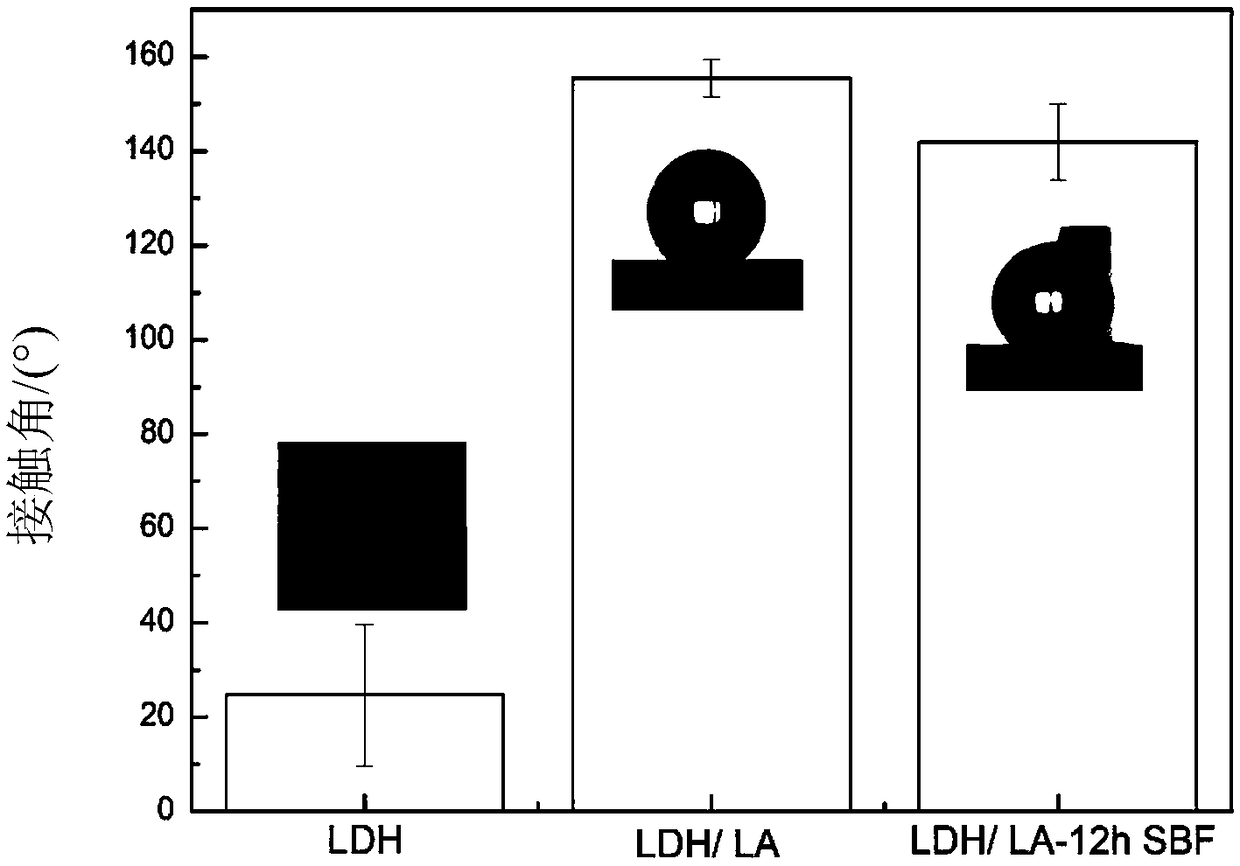

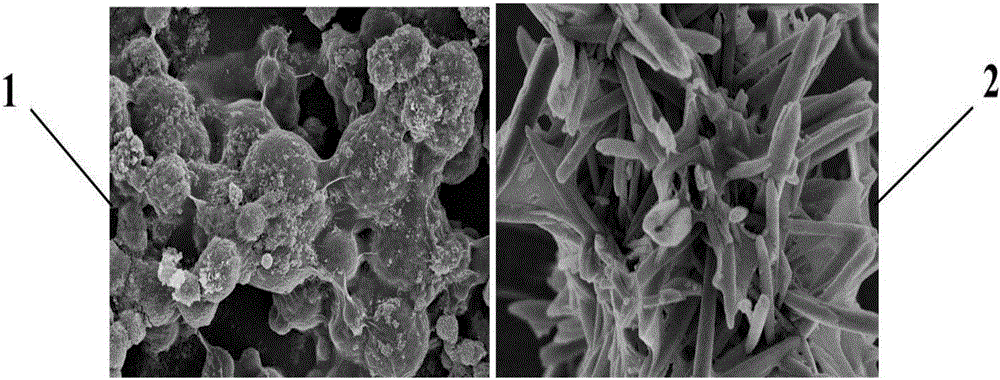

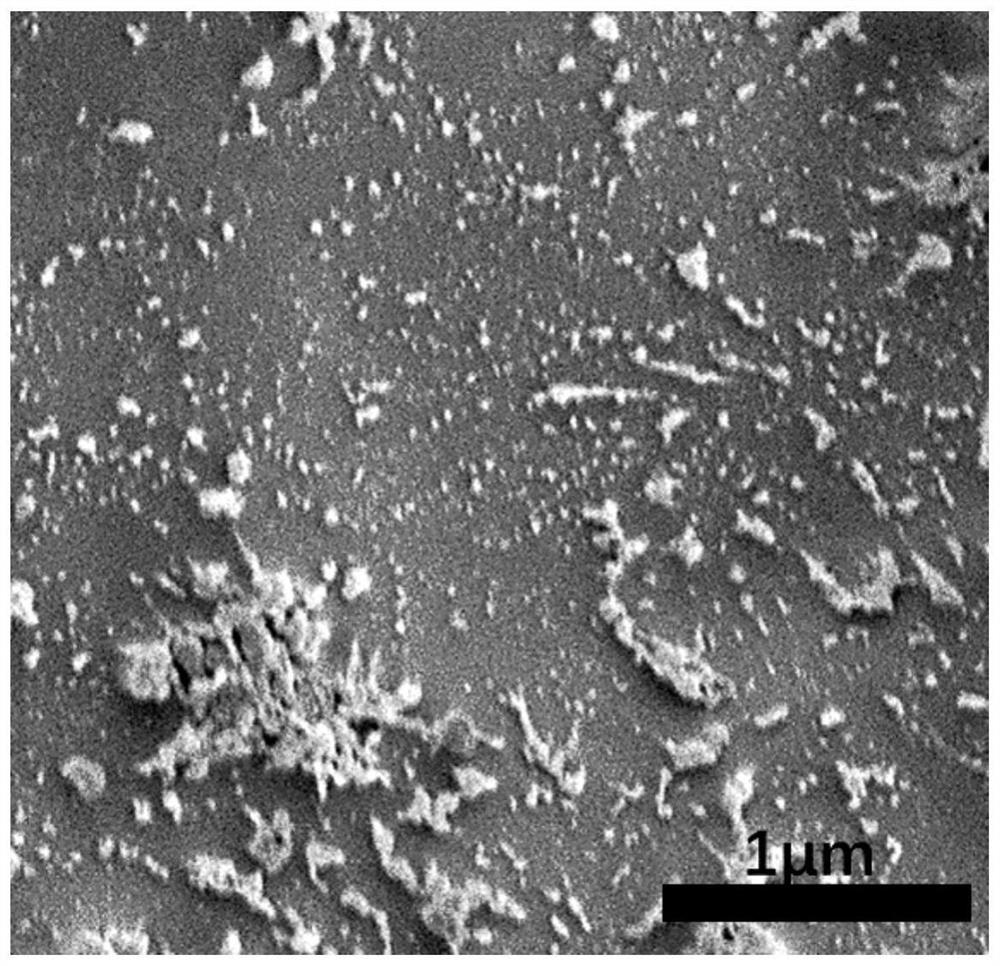

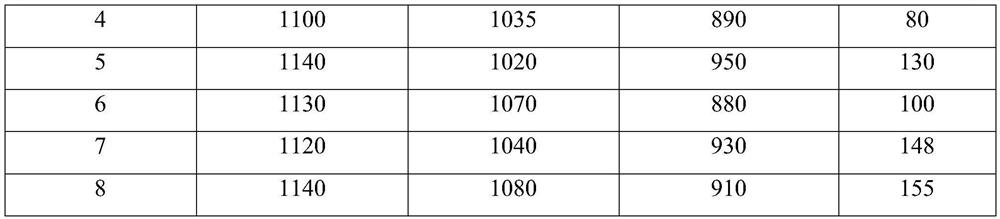

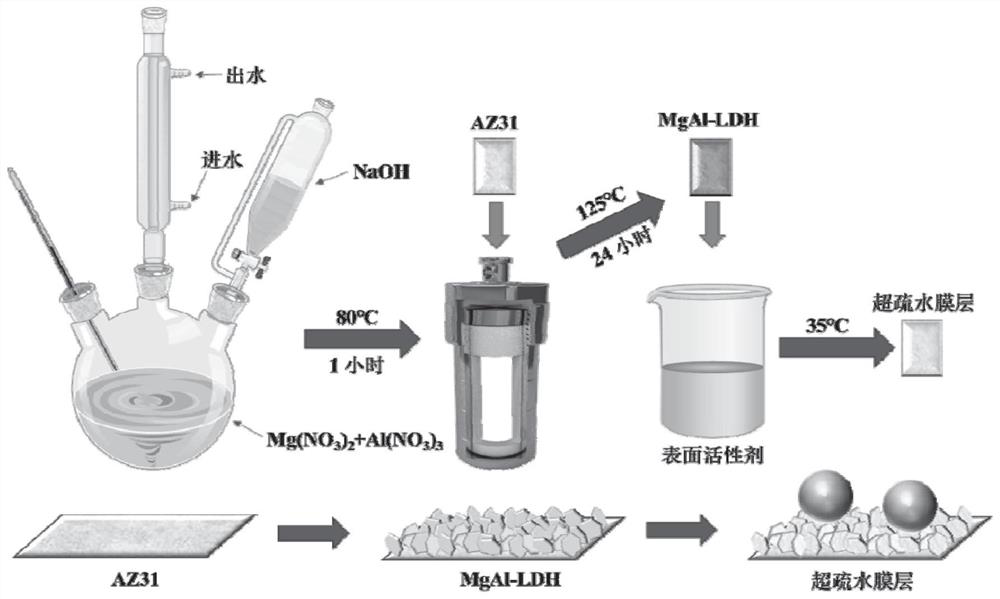

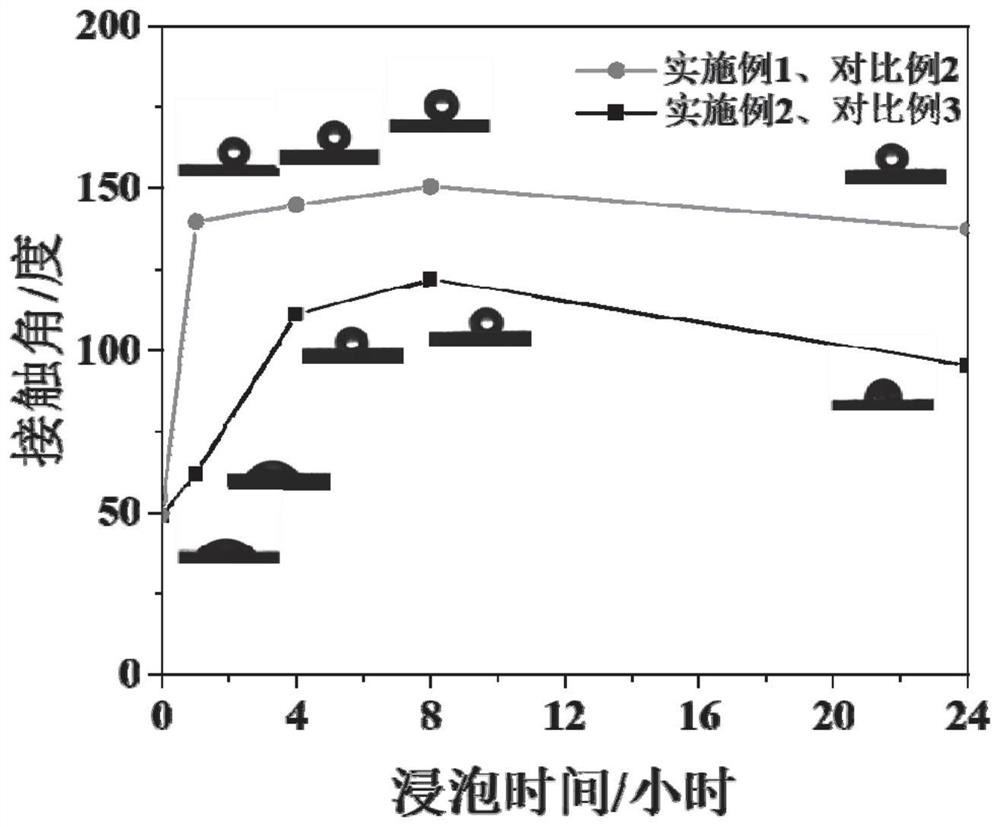

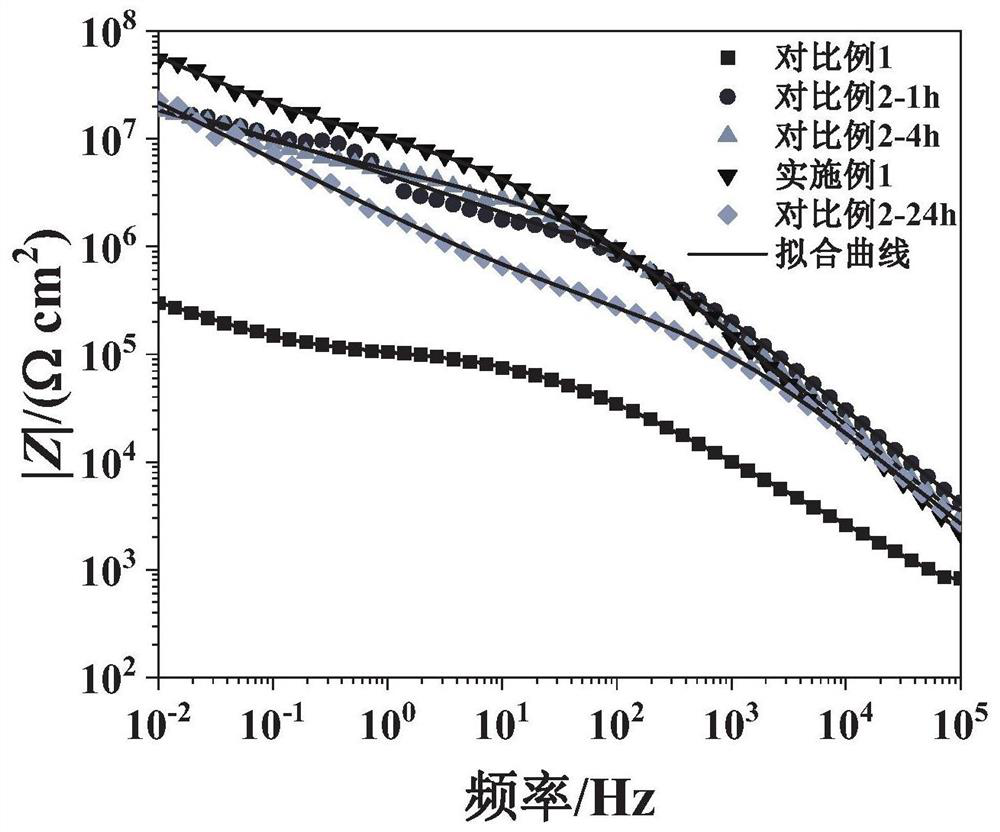

Method for preparing superhydrophobic film on magnesium alloy surface

InactiveCN104561999ASimple processThe preparation process is easy to implementPretreated surfacesMetallic material coating processesHydrotalciteCorrosion

The invention provides a preparation method of a superhydrophobic film on a magnesium alloy surface, which mainly comprises the following steps: preparing a mixed solution (pH value is 10-11) containing 0.1M (molar concentration) Zn(CH3COO)2.2H2O and 0.05M Al(OH)3, transferring the solution into a stainless steel hydrothermal synthesis reaction kettle, vertically inserting a pretreated magnesium alloy sample into the mixed solution, and reacting in the 60-DEG C thermostat water bath for 5 hours to obtain a micro / nano multilevel-structure rough surface on the magnesium alloy surface; and immersing the rough surface in a 0.05M stearic acid ethanol solution for 5 hours to prepare the superhydrophobic film on the magnesium alloy surface. The electrochemical testing on the corrosion resistance of the magnesium alloy before and after superhydrophobic treatment detects that the superhydrophobic film can obviously enhance the corrosion resistance of the magnesium alloy. Besides, the prepared hydrotalcite-like superhydrophobic film has high superhydrophobicity stability in an atmospheric environment.

Owner:UNIV OF SCI & TECH BEIJING

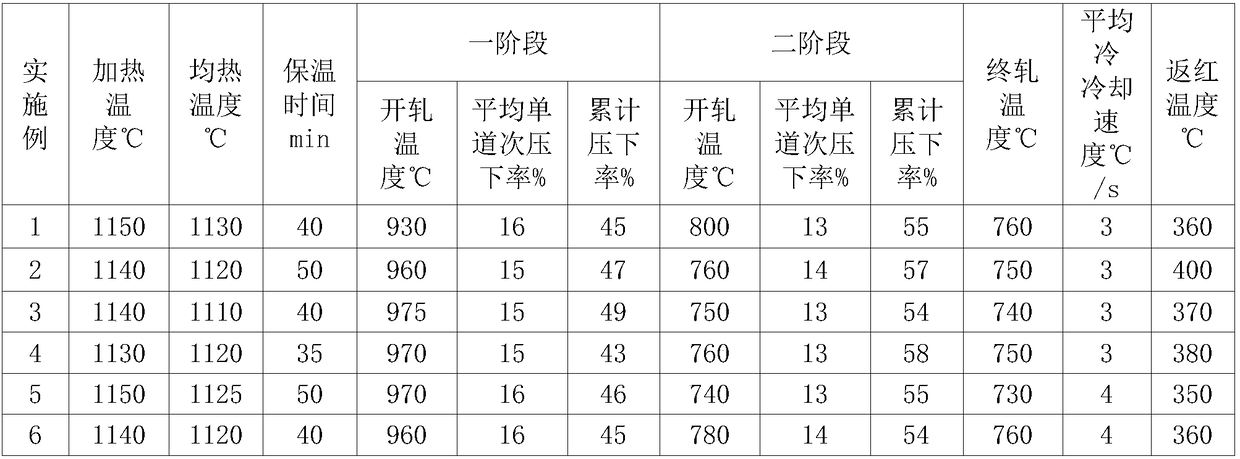

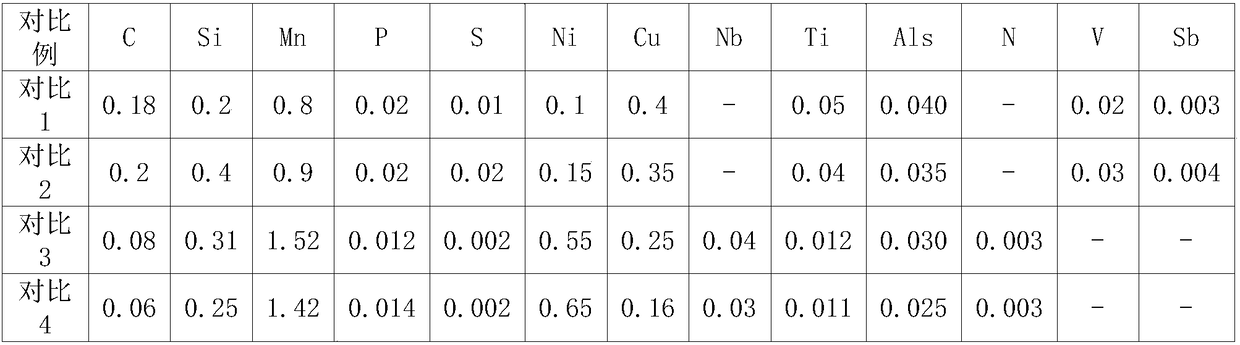

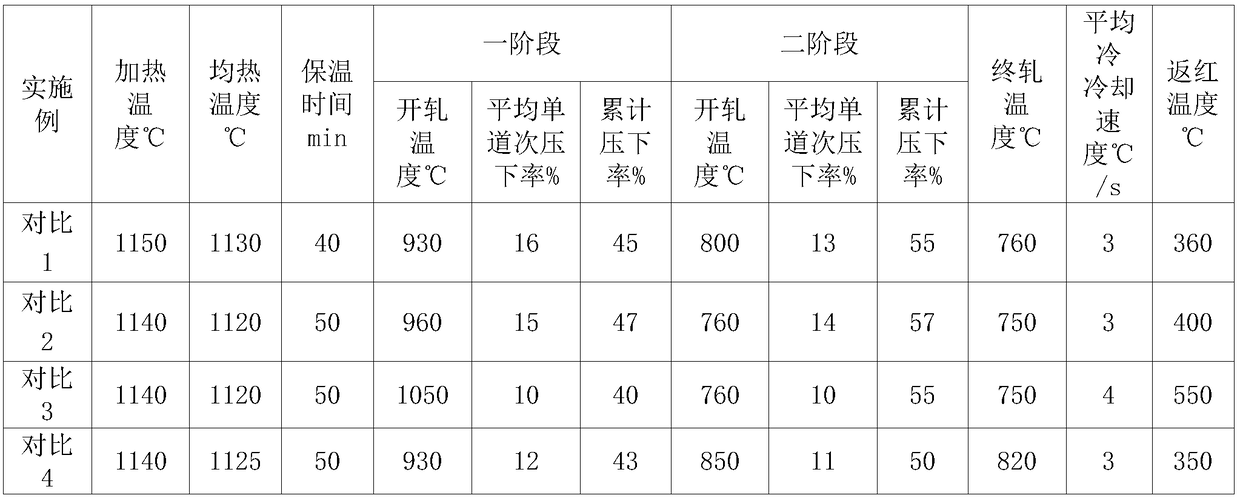

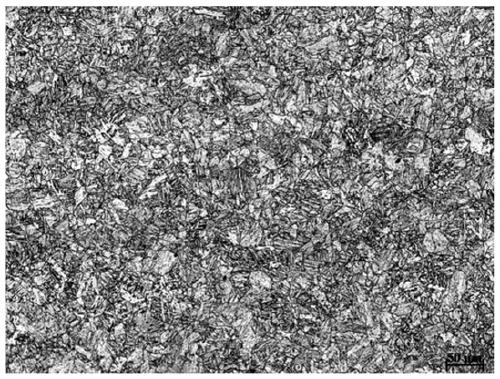

High-strength thick steel plate with excellent crack-arrest property and manufacturing method thereof

The invention relates to a high-strength thick steel plate with an excellent crack-arrest property. The steel plate has the following characteristics: a wide-plate tensile value Kca for determining the crack-arrest property is larger than 6000 N / mm<1.5>; yield strength at the positions, which are respectively 1 / 4 and 1 / 2 the thickness of the steel plate away from the surface of the steel plate, isno less than 460 MPa; tensile strength is 570 to 720 MPa; Charpy impact energy at minus 40 DEG C is no less than 200 J; and a zero-ductility transition temperature is less than minus 60 DEG C. The steel plate provided by the invention comprises the following components by weight: 0.04 to 0.16% of C, 0.1 to 0.5% of Si, 0.9 to 1.6% of Mn, 0.1 to 0.3% of Cu, 0.2 to 0.9% of Ni, no more than 0.02% ofP, no more than 0.02% of S, 0.01% to 0.05% of Als, 0.002 to 0.010% of N, 0.02% to 0.05% of Nb and 0.01 to 0.03% of Ti, with the balance being Fe and unavoidable impurities. According to the invention,through optimization of chemical components of a high-strength steel plate and adoption of controlled rolling and controlled cooling processes for controlling the microscopic structure and grain sizein a plate thickness direction, the crack-arrest steel plate with high yield and stable strength and toughness is obtained. The high-strength thick steel plate provided by the Invention is used as container vessel steel, and has the characteristics of excellent crack-arrest toughness, high yield strength, excellent low-temperature toughness and large thickness.

Owner:ANGANG STEEL CO LTD

Method of conducting in-situ growth of hydrotalcite-like membrane on surface of magnesium alloy on basis of electric field regulation and control and hydrotalcite-like membrane

ActiveCN108624930ASimple processThe preparation process is easy to implementElectrolytic inorganic material coatingProsthesisIon exchangeIon

The invention provides a method of conducting in-situ growth of a hydrotalcite-like membrane on the surface of magnesium alloy on the basis of electric field regulation and control and the hydrotalcite-like membrane. The method comprises the following steps that (1) the surface of magnesium alloy is preprocessed; (2) an Mg(OH)2 / Mg-Mn composite hydrotalcite-like membrane grows in an in-situ mode ina saturated carbonic acid solution of manganese ion salt by using a preprocessed magnesium alloy substrate as a working electrode and using a platinum electrode as a counter electrode under the action of a pulsed electric field; and (3) magnesium alloy prepared in the step (2) and equipped with the hydrotalcite-like membrane is put in a 0.04mol / L laurate ethanol solution and soaked in the switch-on state of a pulsed power source, acid group ion exchange is conducted, and therefore a super-hydrophobic hydrotalcite-like membrane layer with a petal-shaped cluster structure is obtained on the surface of magnesium alloy. By means of the directional nucleation effect of the pulsed electric field, an alternating electric field regulates and controls the solution micro-region ion concentration, and therefore controllable preparation of the hydrotalcite-like membrane structure is achieved. The method is simple in technology, the hydrophobicity of the hydrotalcite-like membrane is remarkably improved, and the method can be widely applied to the bio-medical fields such as the body implantation field.

Owner:NANJING INST OF TECH

High strength steel for thick wall water pipe and manufacturing method thereof

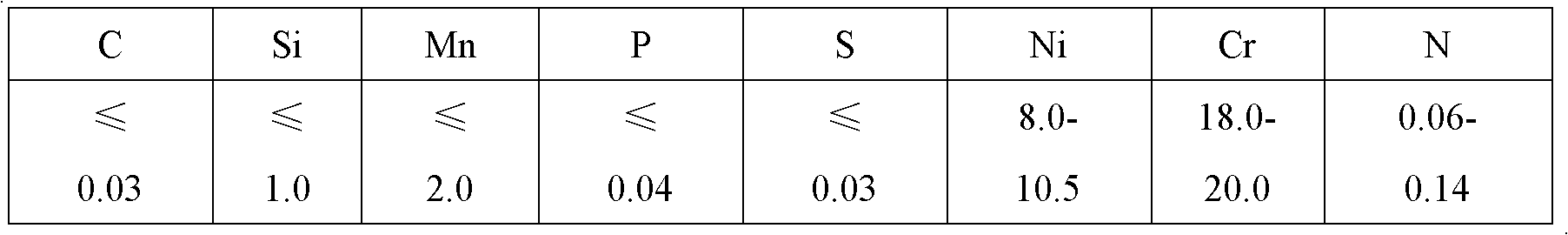

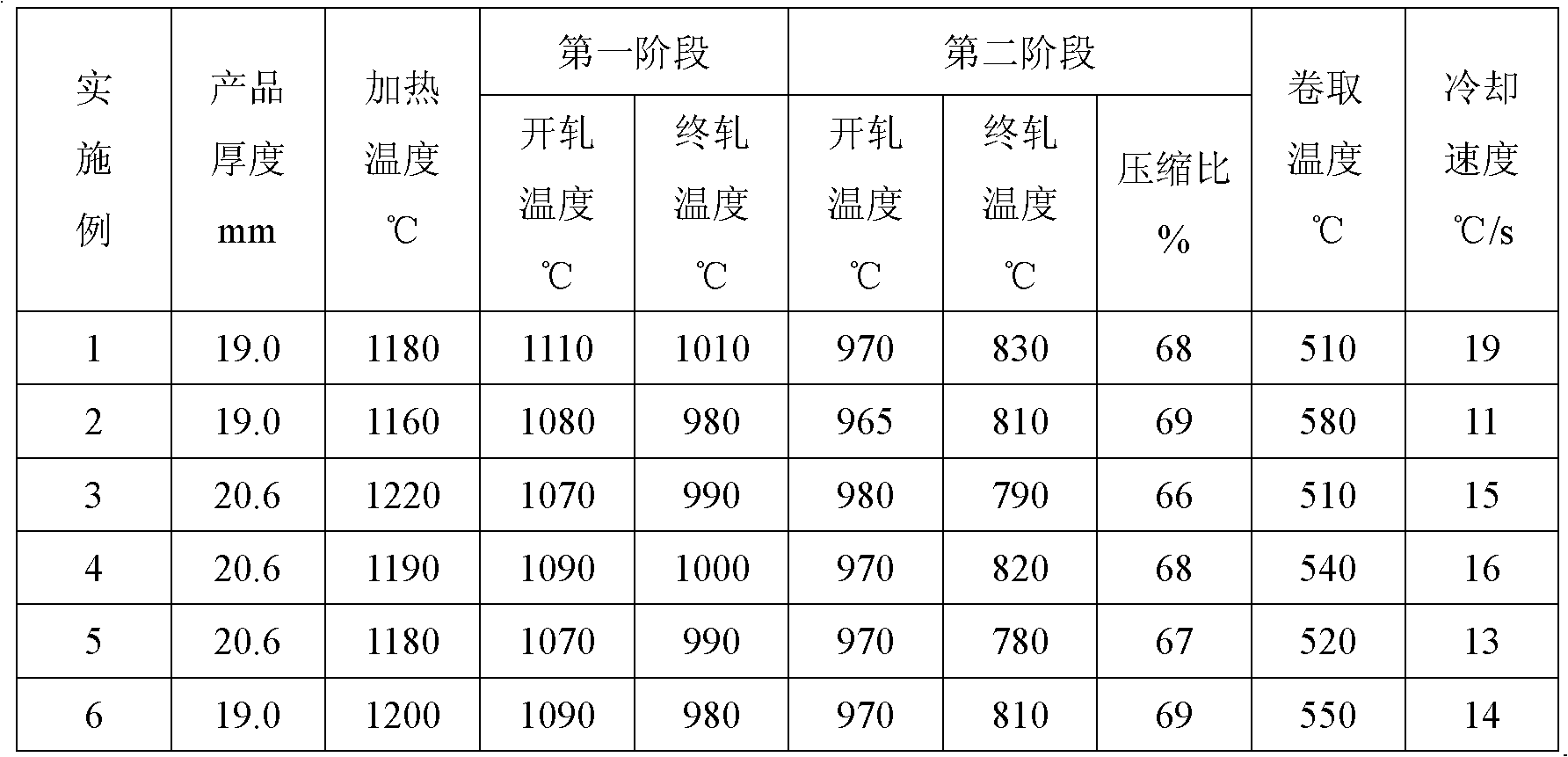

The invention provides a high strength steel for a thick wall water pipe. The steel comprises the following components: 0.040%-0.070% of C, 0.10%-0.40% of Si, 1.50%-1.65% of Mn, 0.050%-0.080% of Nb, 0.030%-0.050% of V, 0.20%-0.30% of Cr, 0.005%-0.025% of Ti, 0.015%-0.050% of Als, less than or equal to 0.020% of P, less than or equal to 0.008% of S, less than or equal to 0.008% of N, less than or equal to 0.002% of O, and the balance Fe and inevitable impurities. The manufacturing method of the steel includes: conducting continuous casting to make a continuous casting plate blank, subjecting the continuous casting plate blank directly to hot charging furnace heating at 500-850DEG C, heating the continuous casting plate blank by a reheating furnace to 1150-1230DEG C, discharging it, then carrying out two-stage controlled rolling by roughing rolling and finish rolling units, controlling the initial rolling temperature of rough rolling at 1180-1100DEG C and the final rolling temperature of rough rolling at 1010-960DEG C, keeping the initial rolling temperature of finish rolling at 980-920DEG C and the final rolling temperature of finish rolling at 780-850DEG C, and maintaining the compression ratio of finishing rolling greater than 60%; then subjecting a steel strip to rapid cooling by means of laminar cooling at a speed of 10-20DEG C / s; and performing reeling at 500-580DEG C.

Owner:ANGANG STEEL CO LTD

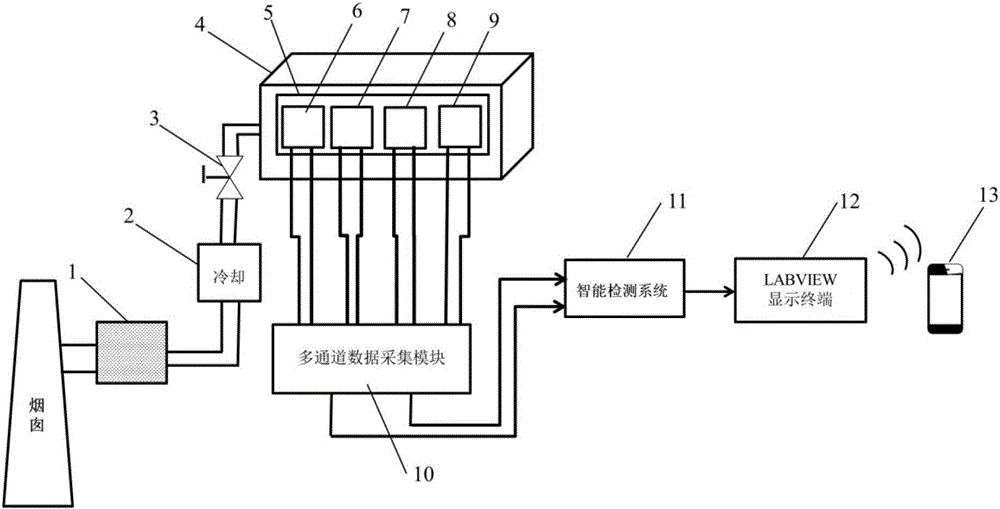

Intelligent ultralow-concentration monitoring device for gaseous pollutants discharged by thermal power plant

ActiveCN105954323AThe manufacturing process is easy to implementImprove gas sensing performanceMaterial analysis by electric/magnetic meansSensor arrayGas detector

The invention discloses an intelligent ultralow-concentration monitoring device for gaseous pollutants discharged by a thermal power plant. The intelligent ultralow concentration monitoring device comprises a smoke-dust separator, a smoke cooling module, a smoke testing cavity, a graphene-based gas sensor array, a multi-channel data acquisition module, an intelligent detecting system, a LABVIEW terminal display system and a wireless transmitting and monitoring system. According to the device, smoke discharged by the thermal power plant is subjected to dust removal through the smoke-dust separator and then cooled through the smoke cooking module, and enters the smoke testing cavity provided with the graphene-based gas sensor array, array signals are acquired by the multi-channel data acquisition module, smoke component concentrations are output through the intelligent detecting system with a genetic particle swarm-radial basis neural network as a core, the detected concentrations are remotely transmitted to the environment protection supervision department or a mobile phone monitoring terminal of working personnel through the wireless transmitting and monitoring system. The concentration monitoring device for smoke discharge components of the thermal power plant has the advantages of being low in detection limit, high in sensitivity and stability, capable of achieving online detection in real time and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

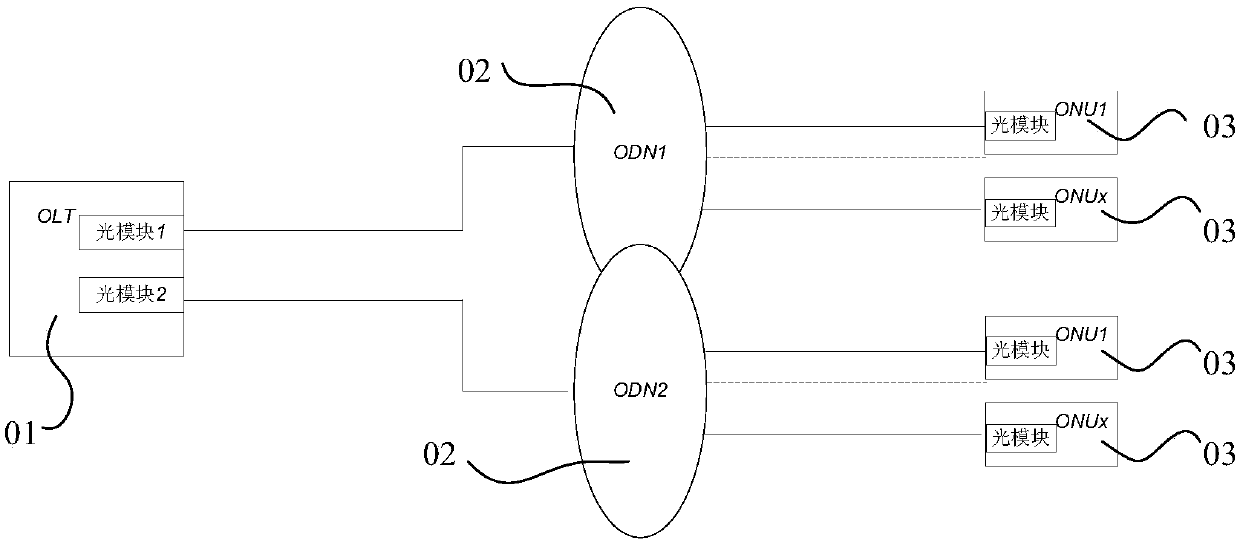

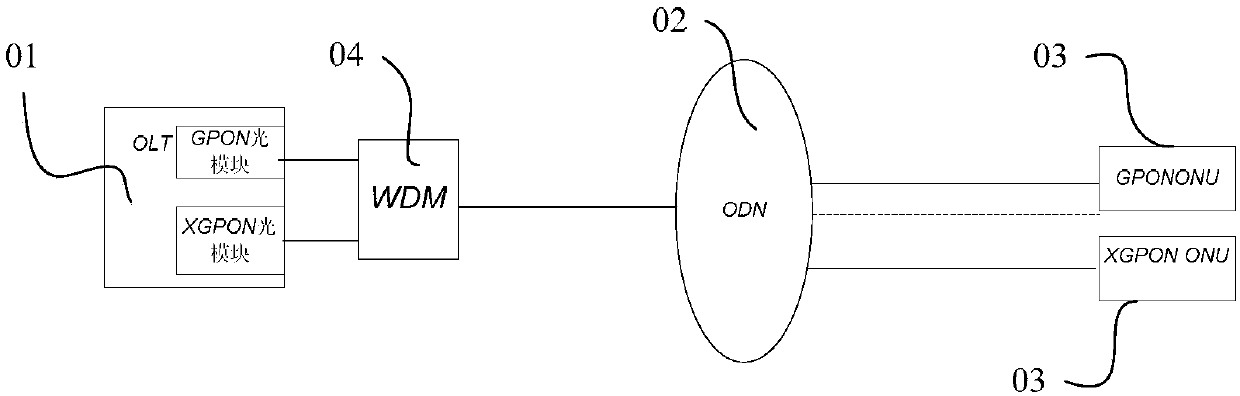

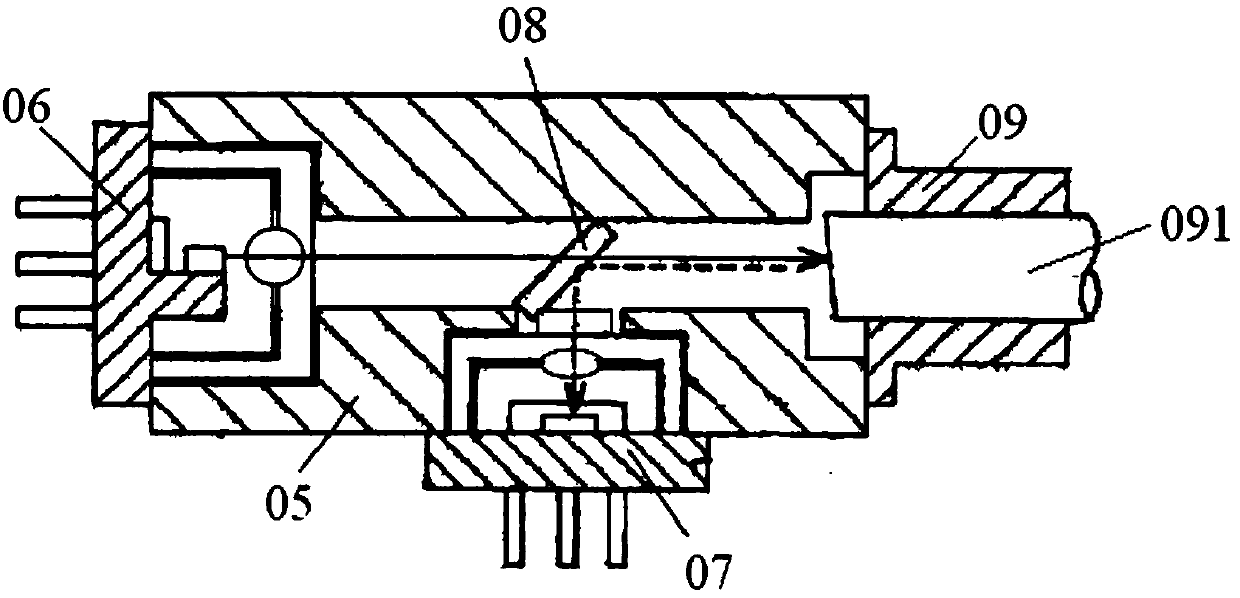

Optical receiving and combined receiving and transmitting assembly, combined optical module, OLT and PON system

ActiveCN109982169AReduce space consumptionAvoid makingMultiplex system selection arrangementsWavelength-division multiplex systemsOptical ModuleEngineering

The embodiment of the invention provides an optical receiving assembly, a combined receiving and transmitting assembly, a combined optical module, an optical line terminal and a passive optical network system. An optical receiving assembly relates to the technical field of optical communication and comprises a first coaxial tube shell, the first coaxial tube shell is provided with a light inlet, and a first wave separator, a first optical receiver, a second optical receiver and an optical lens group are packaged in the first coaxial tube shell; light entering from the light inlet enters the first wave separator, and the first wave separator is used for transmitting an optical signal with a first wavelength and reflecting an optical signal with a second wavelength; the first optical receiver is arranged on a transmission optical path of the first wave separator and is used for receiving an optical signal with a first wavelength; the optical lens set is arranged on a reflection light path of the first wave separator and used for guiding the optical signal of the second wavelength reflected by the first wave separator to the second optical receiver, and the second optical receiver isused for receiving the optical signal of the second wavelength.

Owner:BEIJING HUAWEI DIGITAL TECH

Support device for pouring shear wall

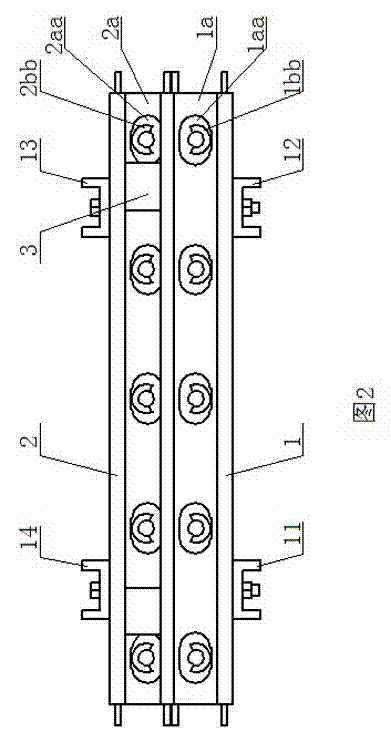

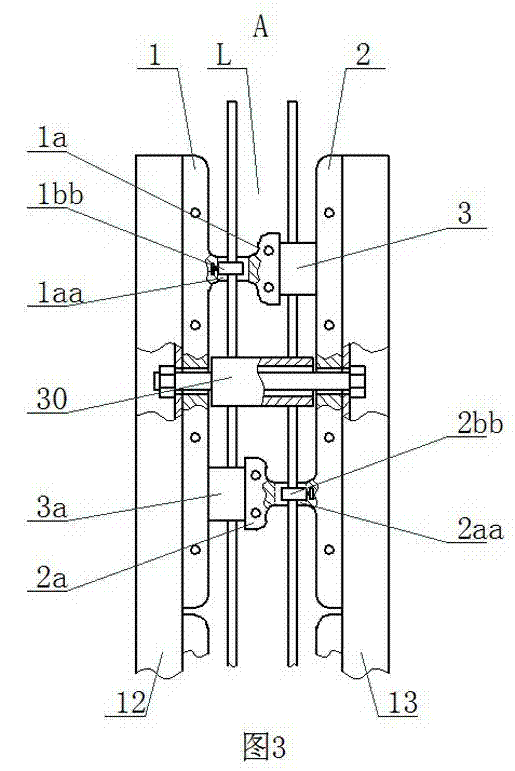

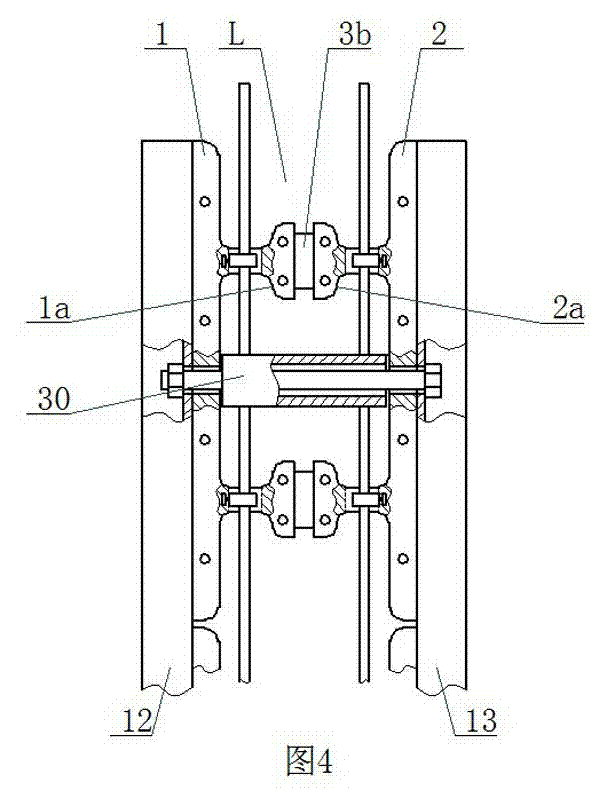

ActiveCN103243906ASimplify the construction processOperation saves time and effortForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksShear wallArchitectural engineering

The invention provides a support device for pouring a shear wall. The support device comprise a plurality of ribbed plates which are longitudinally mutually connected through connectors. Each two ribbed plates are horizontally parallelly distributed. The support device is structurally characterized in that a first ribbed plate is parallel with a second ribbed plate in the length direction, a spatial part is formed between the first ribbed plate and the second ribbed plate, a first protruding rib on the first ribbed plate and a second protruding rib on the second ribbed plate are disposed in the spatial part, the first protruding rib corresponds to the second ribbed plate, a cushion block is mounted between the first protruding rib and the second ribbed plate, the second protruding rib corresponds to the first ribbed plate, a cushion block is mounted between the second protruding rib and the first ribbed plate, the connectors are disposed on the outer sides of the first ribbed plate and the second ribbed plate and respectively connected to the first ribbed plate and the second ribbed plate. The support device uses concrete pouring after industrialized production and field assembling and removes the connectors after the shear wall is manufactured, and the problems of complex construction procedures, low construction efficiency and high construction cost in the prior art can be solved.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

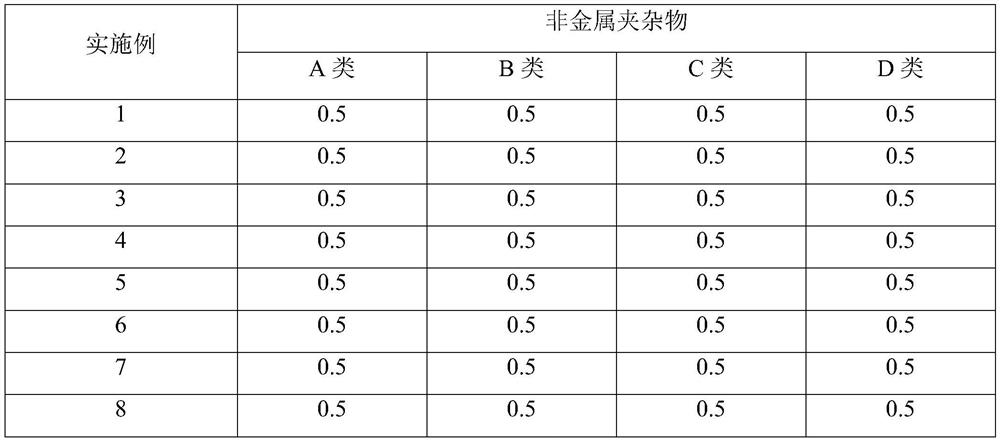

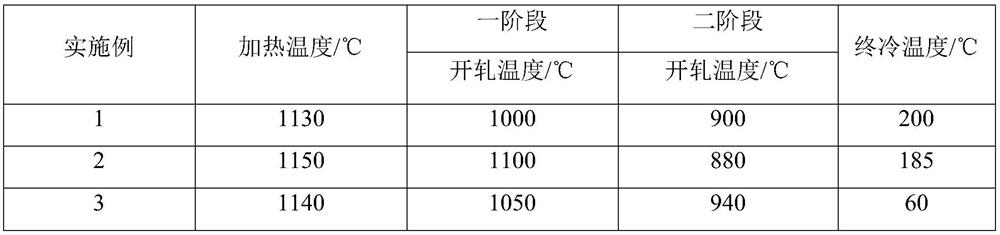

Steel with high low temperature fracture toughness and used for ocean engineering and manufacturing method thereof

ActiveCN108728743ASolve segregationImprove low temperature fracture toughnessReduction rateUltimate tensile strength

The invention discloses steel with high low temperature fracture toughness and used for ocean engineering and a manufacturing method thereof. The steel comprises the following components: 0.05%-0.10%of C, 0.2%-0.5% of Si, 1.0%-1.5% of Mn, 0.20%-0.50% of Cu, 1.00%-1.50% of Cr, 1.6%-1.8% of Ni, equal to or less than 0.01% of P, equal to or less than 0.01% of S, 0.01%-0.05% of Als, 0.02%-0.04% of Nb, 0.01%-0.02% of Ti, 0.05%-0.07% of V and the balance of Fe and unavoidable impurities. Rolling is controlled by adopting two phases, at the first phase, the rolling temperature is 950-1050 DEG C, andthe single-pass reduction rate is equal to or greater than 15%; at the second phase, the rolling temperature is 840-880 DEG C, and the single-pass reduction rate is greater than 10%; the average cooling rate is greater than 3 DEG C / s, and the self-tempering temperature is 500-600 DEG C; thermal treatment adopts twice quenching and tempering; the yield strength of a steel plate is equal to or greater than 620 MPa, the thickness of the steel plate is 60-100 mm, and the low temperature fracture toughness is high.

Owner:ANGANG STEEL CO LTD

Acidic corrosion-resistant X65 seamless steel pipeline and manufacturing method thereof

InactiveCN106319361AMeet the mechanical performance requirementsControl sulfur and phosphorus contentThermal insulationSteel pipeline

The invention discloses an acidic corrosion-resistant X65 seamless steel pipeline and a manufacturing method thereof. The acidic corrosion-resistant X65 seamless steel pipeline comprises, by weight, 0.08-0.16% of C, 0.15-0.35% of Si, 1.0-1.6% of Mn, 0.02-0.05% of Al, 0.03-0.049% of V, 0.01-0.04% of Ti, 0.20-0.30% of Cu, 0.20-0.30% of Ni, less than or equal to 0.015% of P and less than or equal to 0.005% of S. When C content is less than or equal to 0.12%, CE<Pcm> is less than or equal to 0.25 and when C content is greater than 0.12%, CE<IIW> is less than or equal to 0.42. According to the manufacturing method of the acidic corrosion-resistant X65 seamless steel pipeline, a continuous rolling method is used, a pipe blank is heated to a temperature of 1200-1300 DEG C through an annular furnace, a tube knockout temperature is in a range of 1190-1240 DEG C and a sizing temperature is in a range of 820-850 DEG C, in quenching and tempering treatment, a quenching heating temperature is in a range of 890-910 DEG C, a quenching medium is water, thermal insulation time is greater than or equal to 30min, a tempering temperature is in a range of 580-620 DEG C, thermal insulation time is greater than or equal to 50min, and heating straightening and flaw detection examination are carried out at a temperature greater than or equal to 400 DEG C.

Owner:ANGANG STEEL CO LTD

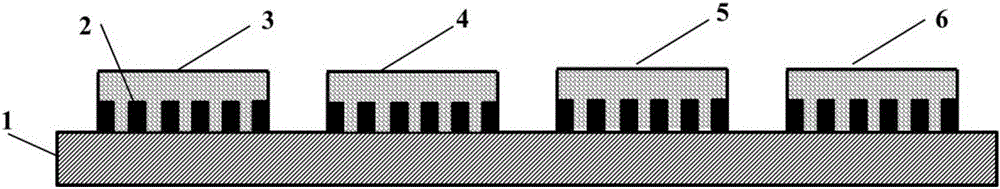

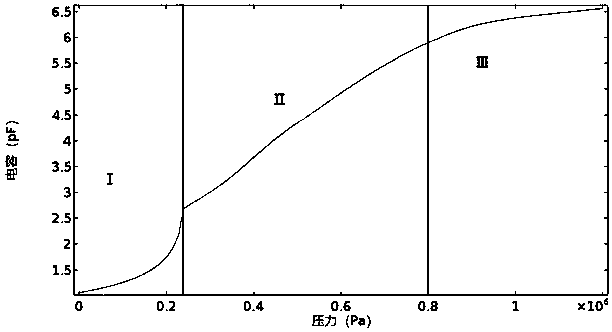

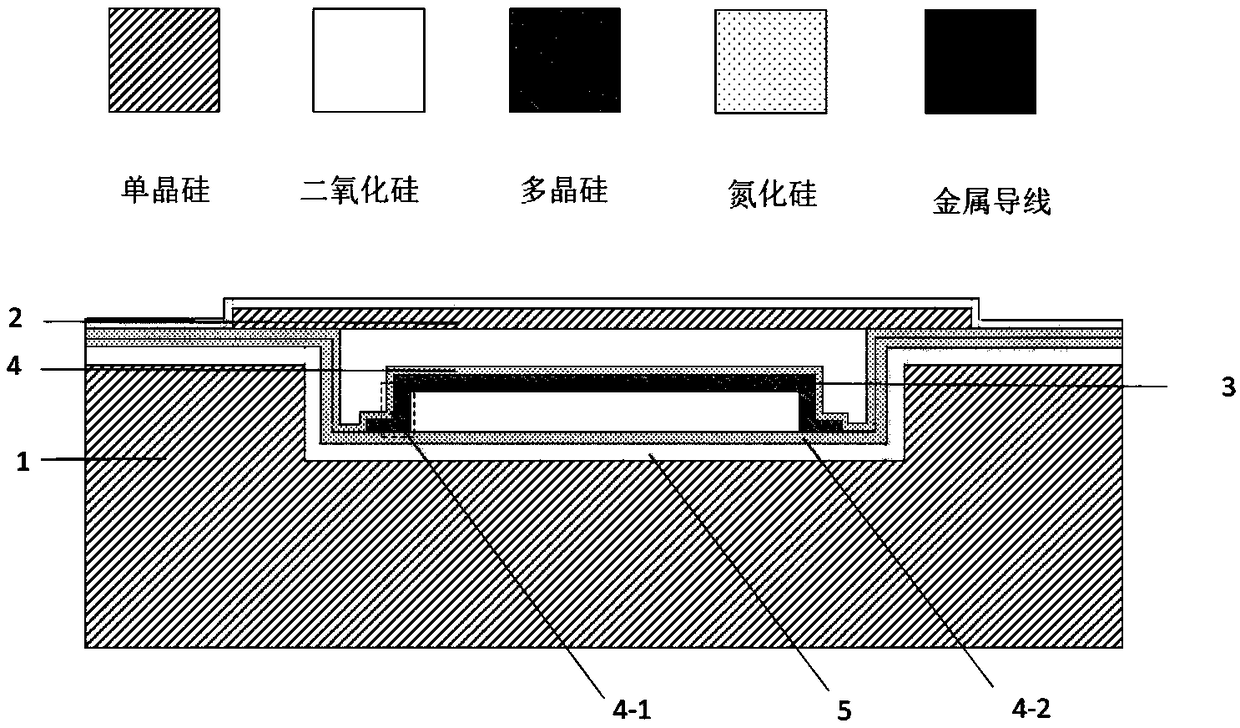

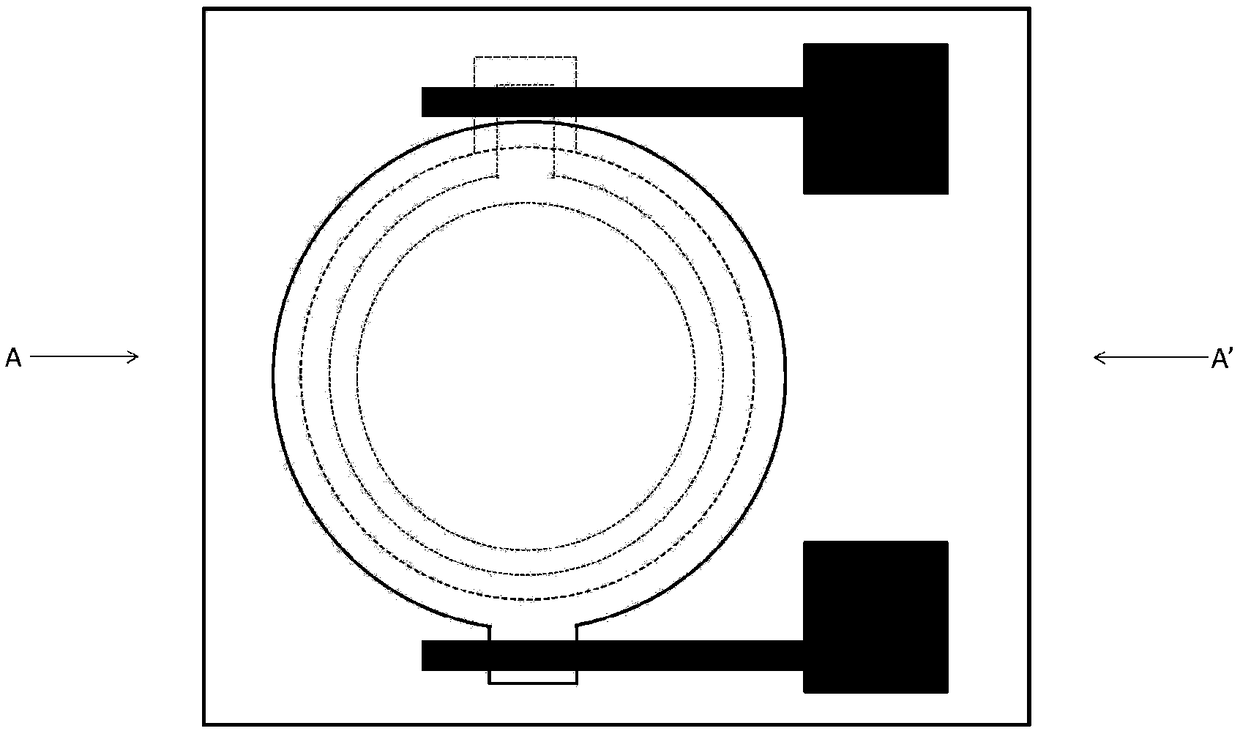

Linkage membrane capacitive pressure sensitive chip and manufacturing method thereof

The invention discloses a linkage membrane capacitive pressure sensitive chip and a manufacturing method thereof. The chip comprises a substrate silicon wafer (1), an upper polar plate (2) and a lowerpolar plate (3); and the upper part of the substrate silicon wafer (1) is provided with a groove, the lower polar plate (3) is disposed inside the groove, and the upper polar plate (2) covers an opening of the groove, so that the groove forms a sealed cavity. In the linkage membrane capacitive pressure sensitive chip and the manufacturing method thereof, the suspended movable lower polar plate isdesigned, so that the upper and lower polar plates become movable structures, thereby improving linearity, and a measuring range of a linear region is increased; a silicon thin film on an SOI substrate is utilized to manufacture the upper polar plate of monocrystalline silicon, so that the thickness of the upper polar plate is more easily controlled; silicon-silicon direct bonding technology is used to transfer a single crystal silicon film of the SOI substrate, and a manufacturing process of the upper polar plate is more easily realized; and by controlling the thickness of a deposited sacrificial layer, a suspended height of the lower polar plate is reasonably controlled, and the accuracy of the suspended height is improved.

Owner:SHENYANG POLYTECHNIC UNIV

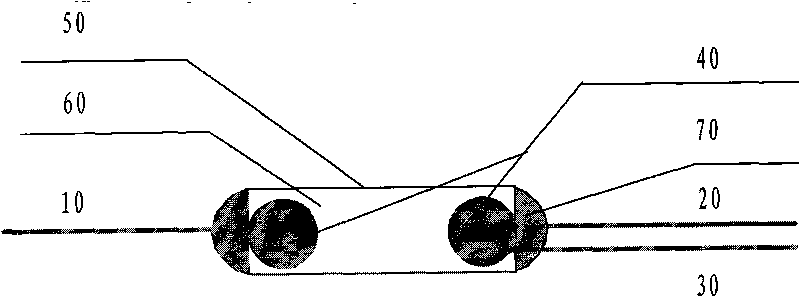

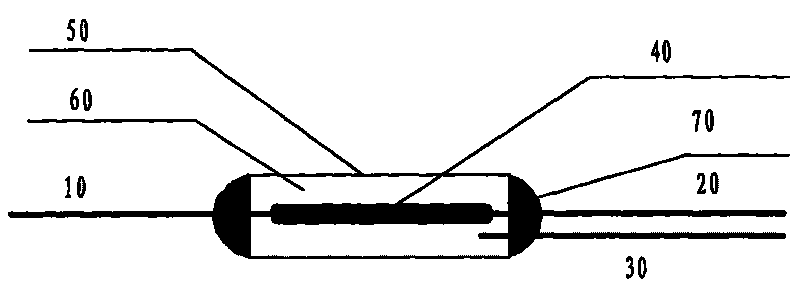

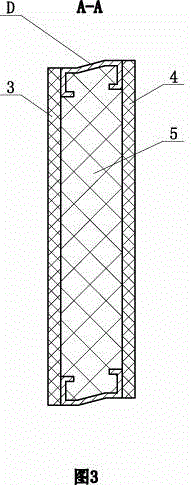

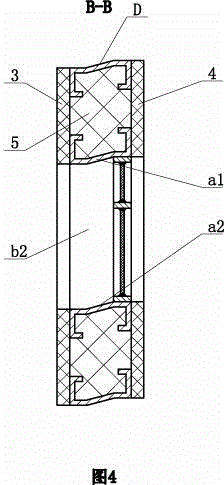

Alarm type thermal fuse-link

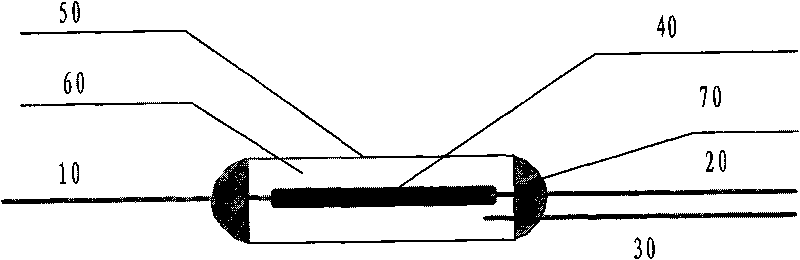

InactiveCN101764005AReduce design difficultyImprove reliabilityEmergency protective devicesSurface tensionClose contact

The invention discloses an alarm type thermal fuse-link which comprises a shell, a first electrode and a second electrode which are arranged in the shell and an alloy fuse-link which is connected with the first electrode and the second electrode. Besides, an alarm electrode is arranged aside the first electrode or the second electrode while a contracting agent is packed around the alloy fuse-link. When the alloy fuse-link automatically fuses caused by the overheating alarm type thermal fuse-link, the fused alloy fusing material contacts towards the electrode direction at two ends and reunitesat the position of the electrode under the action of the surface tension and the contracting agent. Due to the alarm electrode arranged on one end, the reunited fused alloy fusing material connects the alarm electrode with the electrode so as to form a close contact to output a normally closed contact signal. The alarm type thermal fuse-link of the invention can output an alarm remote-control signal while can automatically fuse the circuit by the fuse.

Owner:DELTA GREENTECH CHINA CO LTD

Hanging type wall plate of building

ActiveCN102912932AReduce load-bearing strength requirementsLow costWallsHeat proofingRear quarterDesign standard

The invention provides a hanging type wall plate of a building. The hanging type wall plate comprises at least one wall plate, wherein the wall plate is provided with a framework consisting of an upper light steel section bar, a lower light steel section bar, a left light steel section bar and a right light steel section bar; a top plate is arranged on the section of each light steel section bar; one end of the top plate is connected with the upper end of a first side plate, and the other end of the top plate is connected with the upper end of a second side plate; an inwards bent strip plate is arranged at the lower end of each side plate; a first flat plate is arranged on the left part of the top plate; a second flat plate is arranged on the right part of the top plate; the first flat plate is connected with the second flat plate through an inclined panel; the outer side of the framework is connected with an outer decorative plate; the inner side of the framework is connected with an inner decorative plate; the top of the outer decorative plate is lower than that of the inner decorative plate; a heat preservation material is filled between the outer decorative plate and the inner decorative plate; and a first hanger and a second hanger are respectively connected to the framework. By the hanging type wall plate of a building, the problems that a design standard of a building foundation and a building framework is increased, the engineering manufacturing cost is increased, the building framework is easy to damage, the manufacturing period is long, and the mounting efficiency is low because of heavy weight and relatively high intensity in the prior art can be solved.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

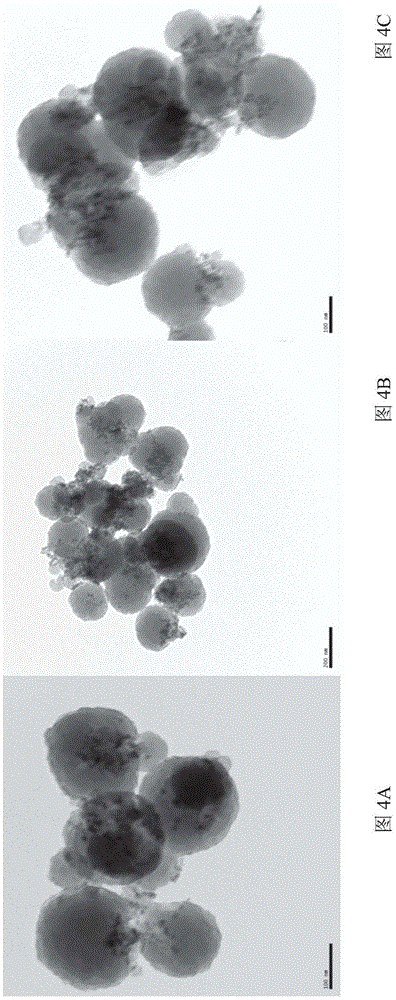

Catalyst for catalyzing oxidation of cyclohexane and preparation method of catalyst

InactiveCN104801344AImprove oxidation efficiencyEasy to recycleOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPropionatePtru catalyst

The invention provides a method for preparing a catalyst for catalyzing oxidation of cyclohexane. The method comprises steps as follows: (A), preparing 5 (p-propionate) phenyl-10,15,20-tri(pyridyl) porphyrin; (B), preparing 5(p-hydroxy) phenyl-10,15,20-tri(pyridyl) porphyrin from 5 (p-propionate) phenyl-10,15,20-tri(pyridyl) porphyrin; (C), preparing metallic coordinated 5-(p-hydroxy) phenyl-10,15,20-tri(pyridyl) porphyrin from 5 (p-hydroxy) phenyl-10,15,20-tri(pyridyl) porphyrin; (D), attaching the metallic coordinated 5-(p-hydroxy) phenyl-10,15,20-tri(pyridyl) porphyrin to at least one magnetic microsphere, and methylating 5-(p-hydroxy) phenyl-10,15,20-tri(pyridyl) porphyrin by the aid of methyl iodide.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

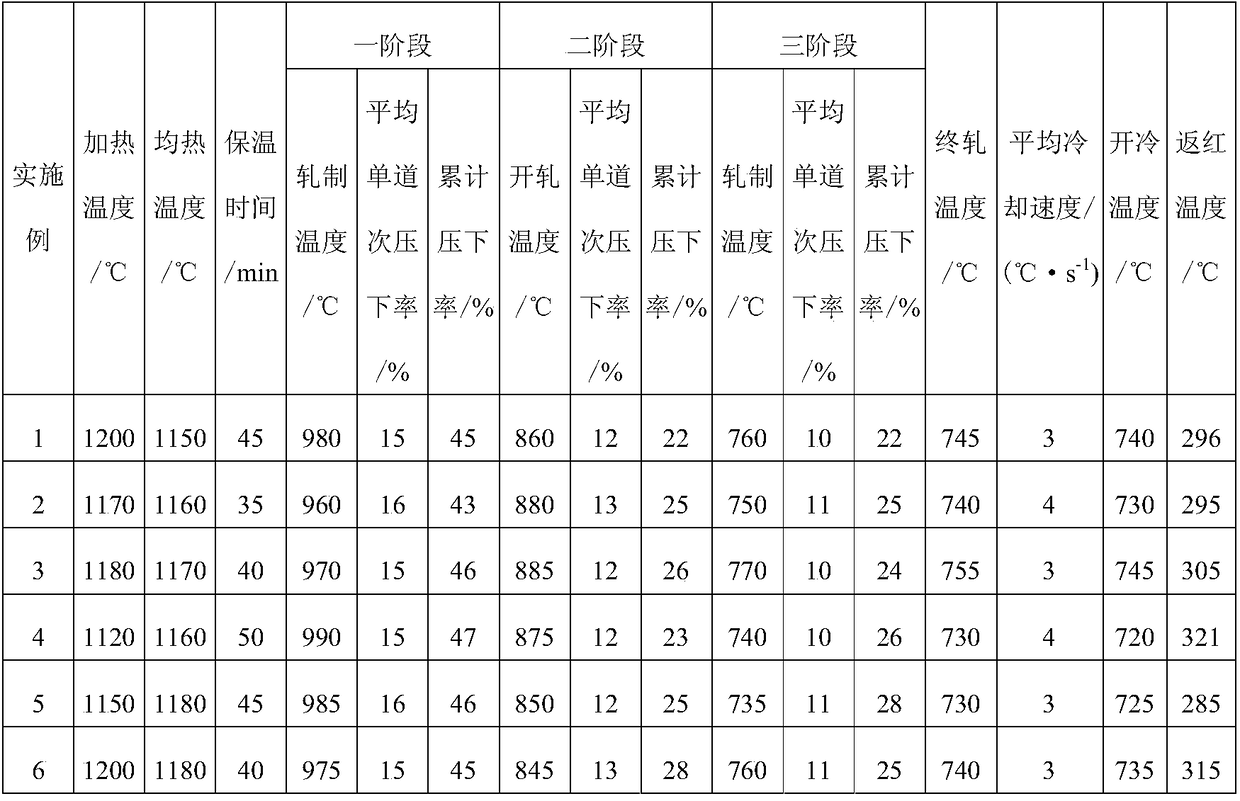

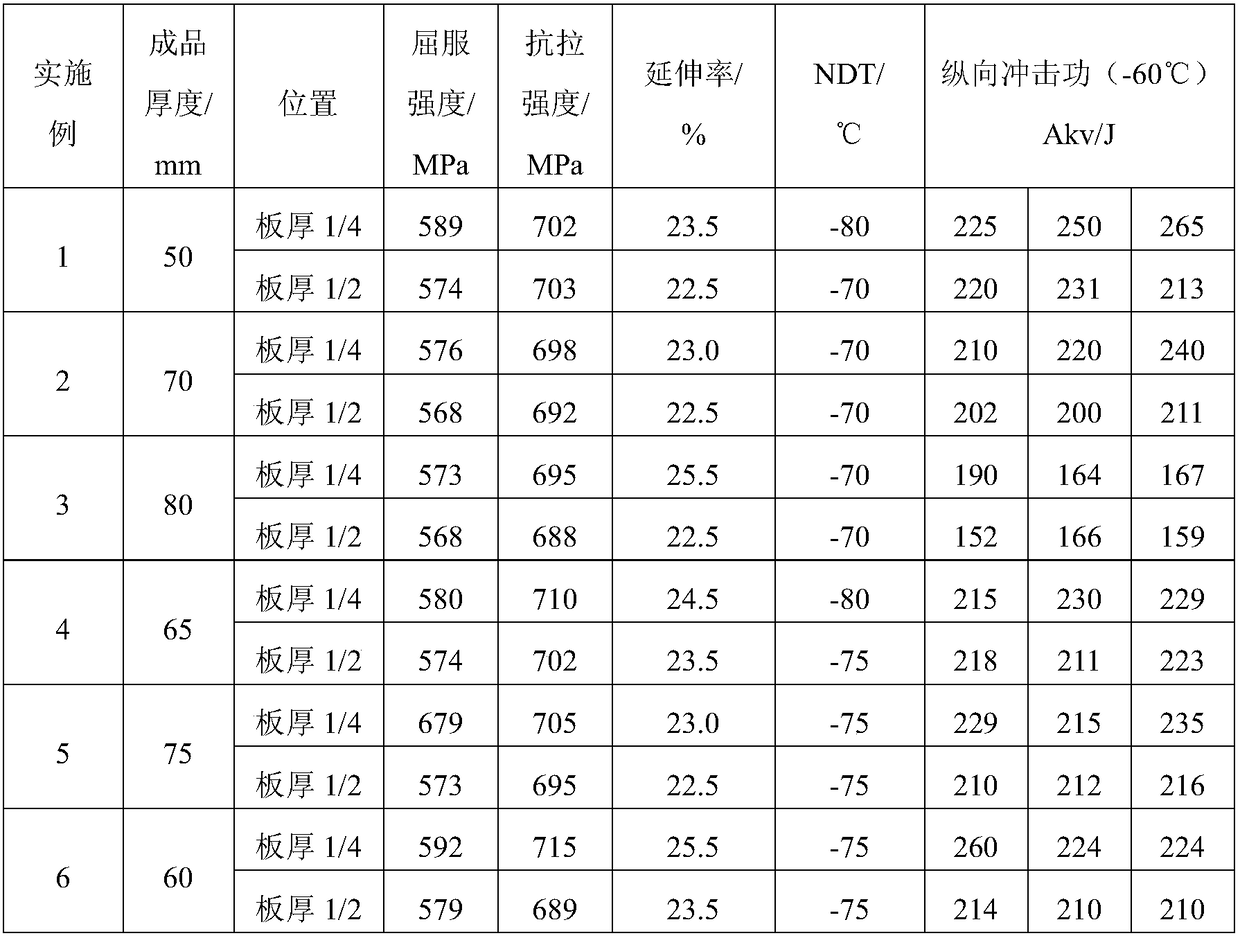

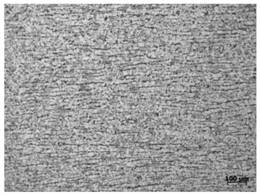

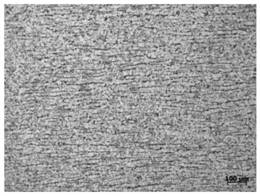

FH550-grade thick plate with excellent low-temperature toughness and manufacturing method thereof

The invention discloses a FH550-grade thick plate with excellent low-temperature toughness and a manufacturing method thereof. The steel contains 0.04% to 0.10% of C, 0.3% to 0.5% of Si, 1.0% to 1.6%of Mn, 0.5% to 0.7% of Cu, 0.5% to 0.7% of Ni, 0.2% to 0.4% of Cr, 0.2% to 0.3% of Mo, less than or equal to 0.01% of P, less than or equal to 0.01% of S, 0.01% to 0.05% of Als, 0.02% to 0.05% of Nb,less than or equal to 0.005% to 0.03% of Ti, 0.04% to 0.06% of V, less than or equal to 0.005% of N, and the balance of Fe and unavoidable impurities. The heating temperature of a casting blank is 1150-1200 DEG C; the first stage rolling temperature is 950-1000 DEG C, and intermittent water cooling is performed after rolling; the second stage rolling temperature is 840-890 DEG C; the third stage rolling temperature is 730-780 DEG C; the average cooling rate is greater than or equal to 3 DEG C / s, the open cooling temperature is 710-750 DEG C, and the red-returning temperature is 280-330 DEG C.The thickness of the produced steel for ship and ocean project is 50-80 mm, and the steel has excellent strength and low temperature toughness.

Owner:ANGANG STEEL CO LTD

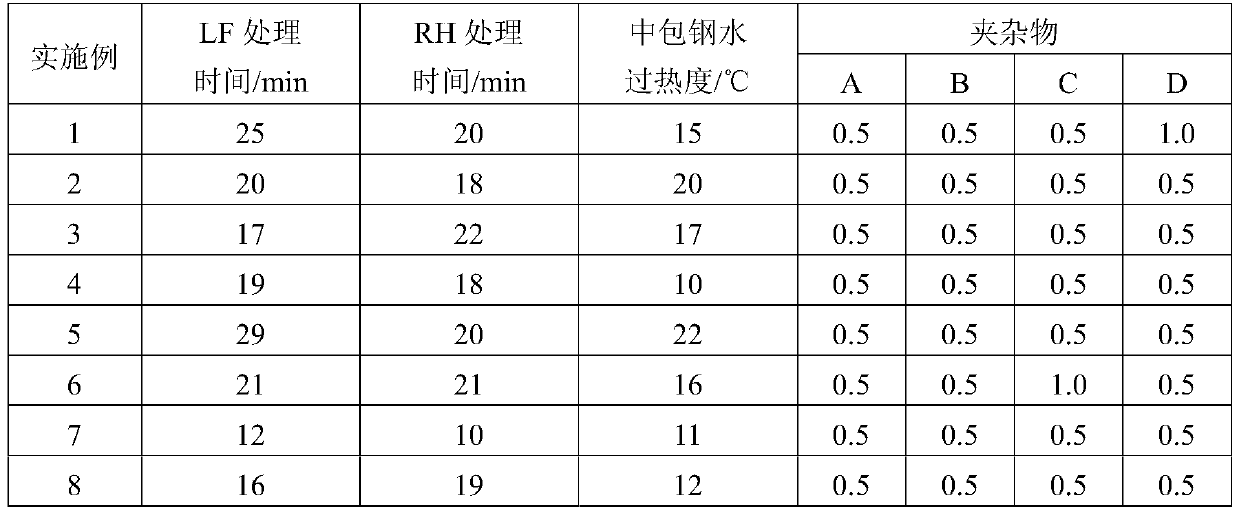

Economical low-temperature steel pipe with good corrosion resistance and manufacturing method of economical low-temperature steel pipe

InactiveCN112011735AGood low temperature impact propertiesImprove corrosion resistanceTemperature control deviceFurnace typesPipeContinuous rolling

The invention provides an economical low-temperature steel pipe with good corrosion resistance and a manufacturing method of the economical low-temperature steel pipe. The steel pipe is prepared fromthe following components in percentage by weight: 0.09%-0.12% of C, 0.25%-0.33% of Si,1.10%-1.29% of Mn, 0.015%-0.03% of Ti, 0.01%-0.024% of Al, less than or equal to 0.012% of P, less than or equal to 0.008% of S, wherein the carbon equivalent CE<Pcm> is less than or equal to 0.22, and the formula of CE<Pcm>=(C+Si / 30+Mn / 20+Cu / 20+Ni / 60+Cr / 20+Mo / 15+V / 10+5B) is met. The manufacturing method comprises the steps of converter smelting, external refining (LF), square billet continuous casting, entering a heating furnace after cooling to the room temperature, pipe billet continuous rolling, reheating, continuous rolling for pipe manufacturing, sizing and heat treatment. By applying the economical low-temperature steel pipe with the good corrosion resistance and the manufacturing method of the economical low-temperature steel pipe, low-temperature impact performance and acid corrosion resistance of the steel pipe are improved, and the steel pipe can be used in a low-temperature environment ofminus 45 DEG C and a hydrogen sulfide corrosion environment.

Owner:ANGANG STEEL CO LTD

Manufacturing method for complete quartz crystal resonator and quartz crystal resonator

InactiveCN101388654ASimple structureSimple and clear structureImpedence networksQuartz crystal resonatorResonance

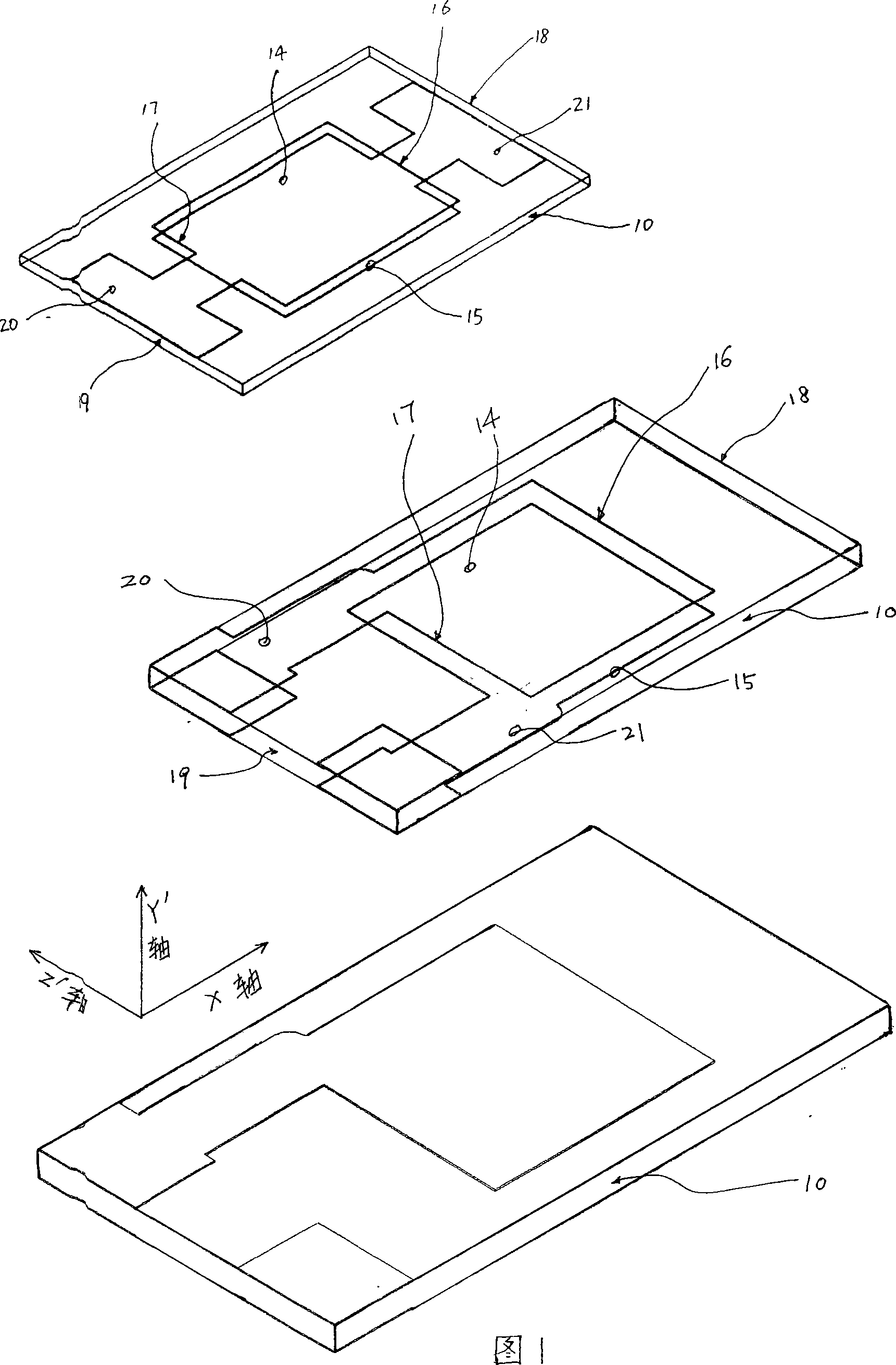

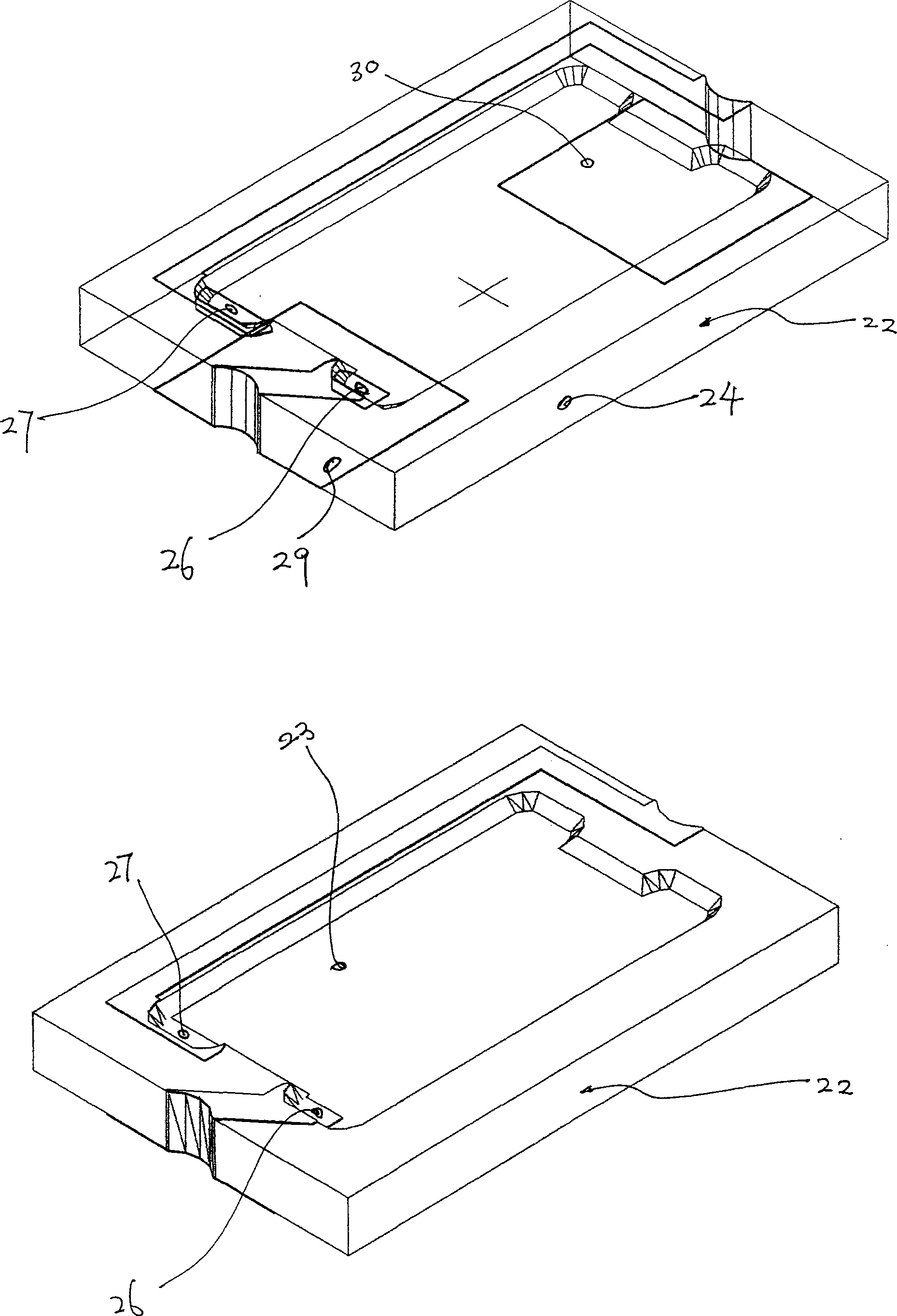

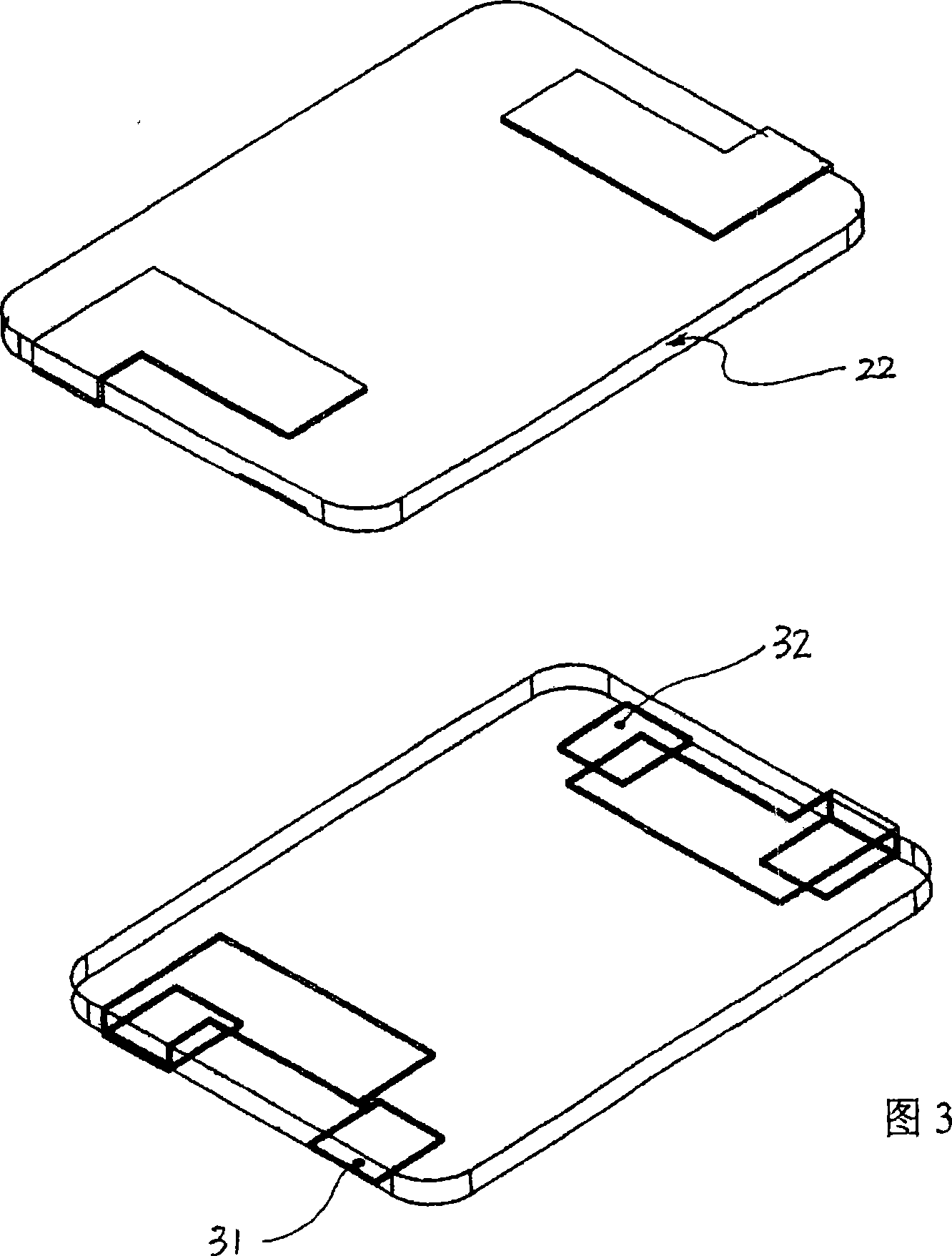

The invention relates to an all silica crystal resonator and a new manufacture method thereof, wherein the all silica crystal resonator comprises a group of resonance plates, wherein the resonance plates are fixed by each base on a base big sheet and are sealed by each outer shell on an outer shell big sheet, a group of resonators are manufactured simultaneously in the manufacture process and are finally decomposed into single resonators, which enables the processing and manufacture process to be simple, the manufacture cost is lowered, and the efficiency is improved. The resonance plates, the outer shell big sheet and the base big sheet are made of quartz crystal materials, the use of ceramic packaging objects is avoided, the problem which is caused by the ceramic packaging objects and by any relations with the ceramic packaging objects or the bases are also avoided, and the service life of the silica crystal resonator is prolonged.

Owner:威廉·比华

X52 seamless pipeline steel pipe with sour corrosion resistance and manufacturing method of X52 seamless pipeline steel pipe

InactiveCN106319362AMeet the mechanical performance requirementsControl sulfur and phosphorus contentRoll mill control devicesMetal rolling arrangementsPunchingSizing

The invention discloses an X52 seamless pipeline steel pipe with sour corrosion resistance and a manufacturing method of the X52 seamless pipeline steel pipe. The X52 seamless pipeline steel pipe comprises, by weight percent, 0.08%-0.16% of C, 0.15%-0.35% of Si, 1.0%-1.6% of Mn, 0.021%-0.05% of Al, 0.03%-0.049% of V, 0.21%-0.30% of Cu, 0.21%-0.30% of Ni, smaller than or equal to 0.015% of P, smaller than or equal to 0.005% of S, and the balance iron and inevitable impurities. When C is smaller than or equal to 0.12%, the carbon equivalent CEPcm is smaller than or equal to 0.25%, and when C is larger than 0.12%, CEIIW is smaller than or equal to 0.43. A continuous rolling method is adopted in the manufacturing method of the seamless pipeline steel pipe, in other words, a pipe blank obtained after continuous casting and continuous rolling is heated to 1,200 DEG C-1,300 DEG C through an annular furnace, the temperature ranges from 1,190 DEG C to 1,240 DEG C after punching, and the sizing temperature is controlled to range 820 DEG C to 850 DEG C. The seamless steel pipe is high in economical efficiency and good in corrosion resistance and can be widely applied to the fields of oil and gas well pipeline pipes in the sour corrosion environment and the like.

Owner:ANGANG STEEL CO LTD

Ocean engineering steel with good low-temperature fracture toughness and manufacturing method thereof

ActiveCN108728743BImprove low temperature fracture toughnessHigh impact energy at low temperatureReduction rateUltimate tensile strength

The invention discloses steel with high low temperature fracture toughness and used for ocean engineering and a manufacturing method thereof. The steel comprises the following components: 0.05%-0.10%of C, 0.2%-0.5% of Si, 1.0%-1.5% of Mn, 0.20%-0.50% of Cu, 1.00%-1.50% of Cr, 1.6%-1.8% of Ni, equal to or less than 0.01% of P, equal to or less than 0.01% of S, 0.01%-0.05% of Als, 0.02%-0.04% of Nb, 0.01%-0.02% of Ti, 0.05%-0.07% of V and the balance of Fe and unavoidable impurities. Rolling is controlled by adopting two phases, at the first phase, the rolling temperature is 950-1050 DEG C, andthe single-pass reduction rate is equal to or greater than 15%; at the second phase, the rolling temperature is 840-880 DEG C, and the single-pass reduction rate is greater than 10%; the average cooling rate is greater than 3 DEG C / s, and the self-tempering temperature is 500-600 DEG C; thermal treatment adopts twice quenching and tempering; the yield strength of a steel plate is equal to or greater than 620 MPa, the thickness of the steel plate is 60-100 mm, and the low temperature fracture toughness is high.

Owner:ANGANG STEEL CO LTD

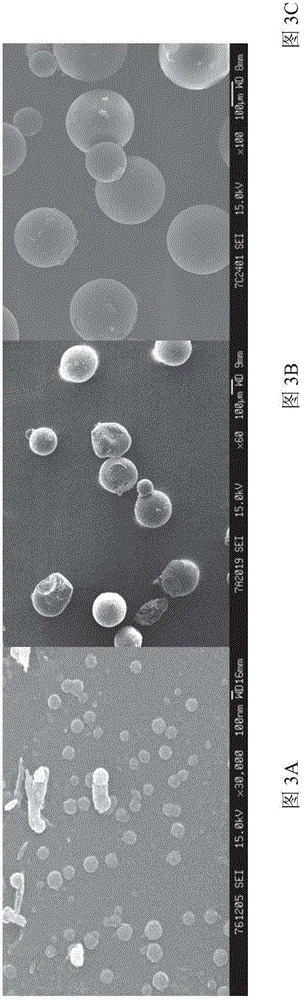

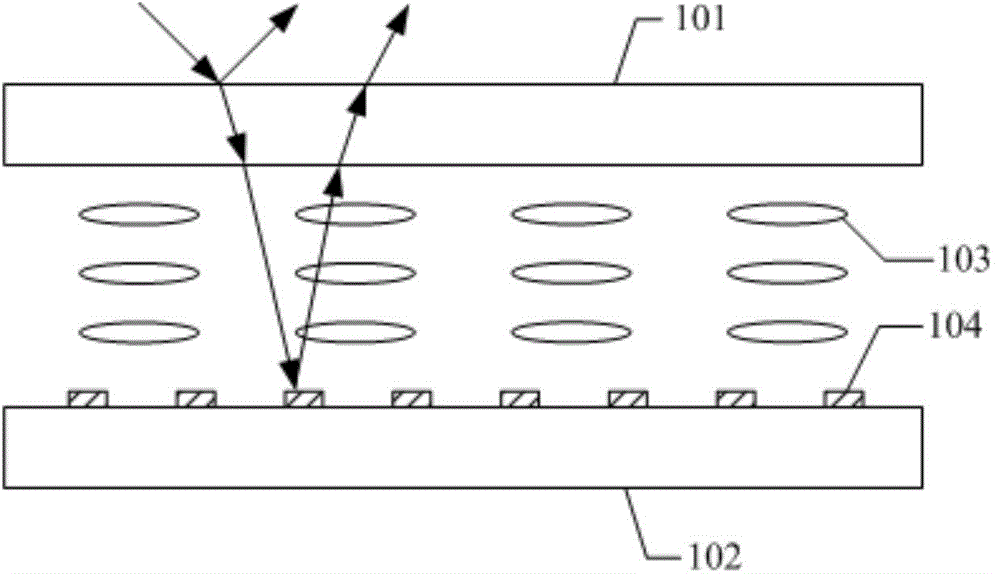

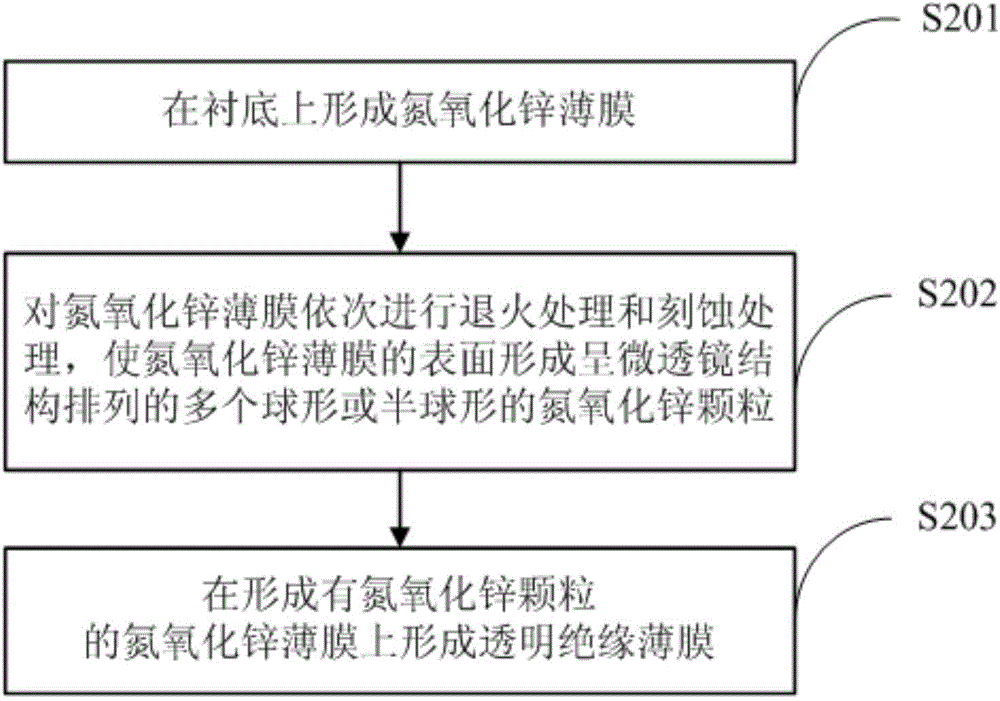

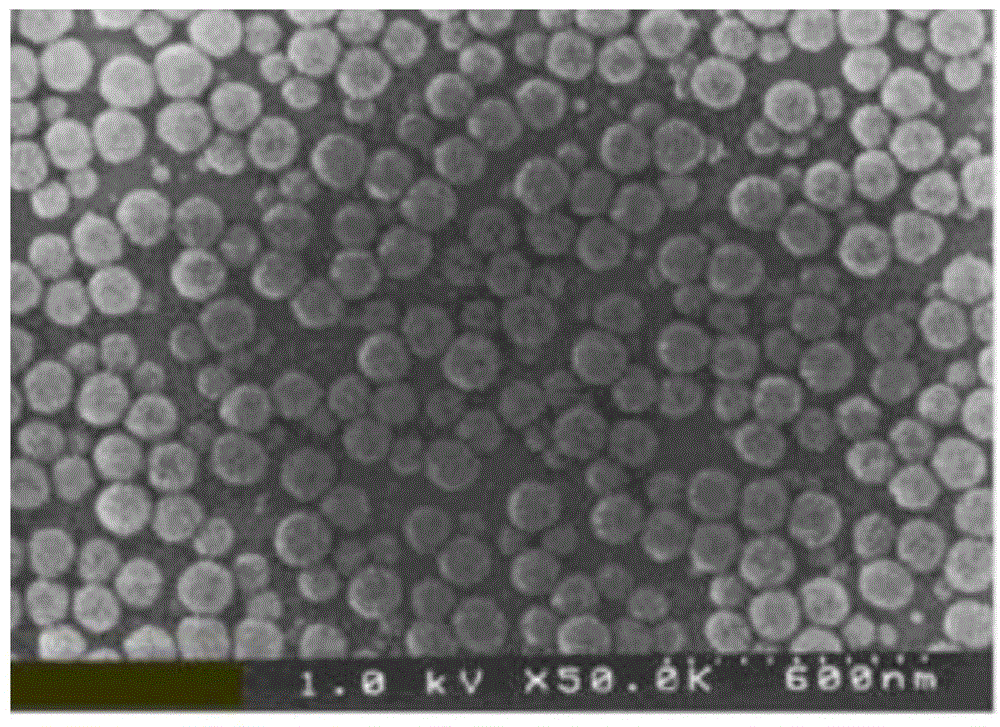

Antireflection film, manufacturing method therefor, display panel, and display device

ActiveCN104865619ADoes not increase thicknessReduce manufacturing costPhotovoltaic energy generationNon-linear opticsManufacturing technologyDisplay device

The invention discloses an antireflection film, a manufacturing method therefor, a display panel, and a display device. The method comprises the steps: forming an N-doped zinc oxide film; sequentially carrying out annealing and etching of the N-doped zinc oxide film, and enabling a plurality of spherical or semispherical N-doped zinc oxide particles arranged in a microlens structure to be formed on the surface of the N-doped zinc oxide film; enabling the N-doped zinc oxide film, the surface of which is provided with the plurality of spherical or semispherical N-doped zinc oxide particles arranged in the microlens structure, to serve as the antireflection film, wherein the shape of the N-doped zinc oxide particles in the formed N-doped zinc oxide film is easy to control, and the manufacturing technology is easy to implement. Moreover, the antireflection film can be integrated on the display panel, and there is no need of pasting technology. Not only the overall thickness and manufacture cost of the display panel cannot be increased, but also the display panel can be prevented from becoming bad in a pasting process.

Owner:BOE TECH GRP CO LTD

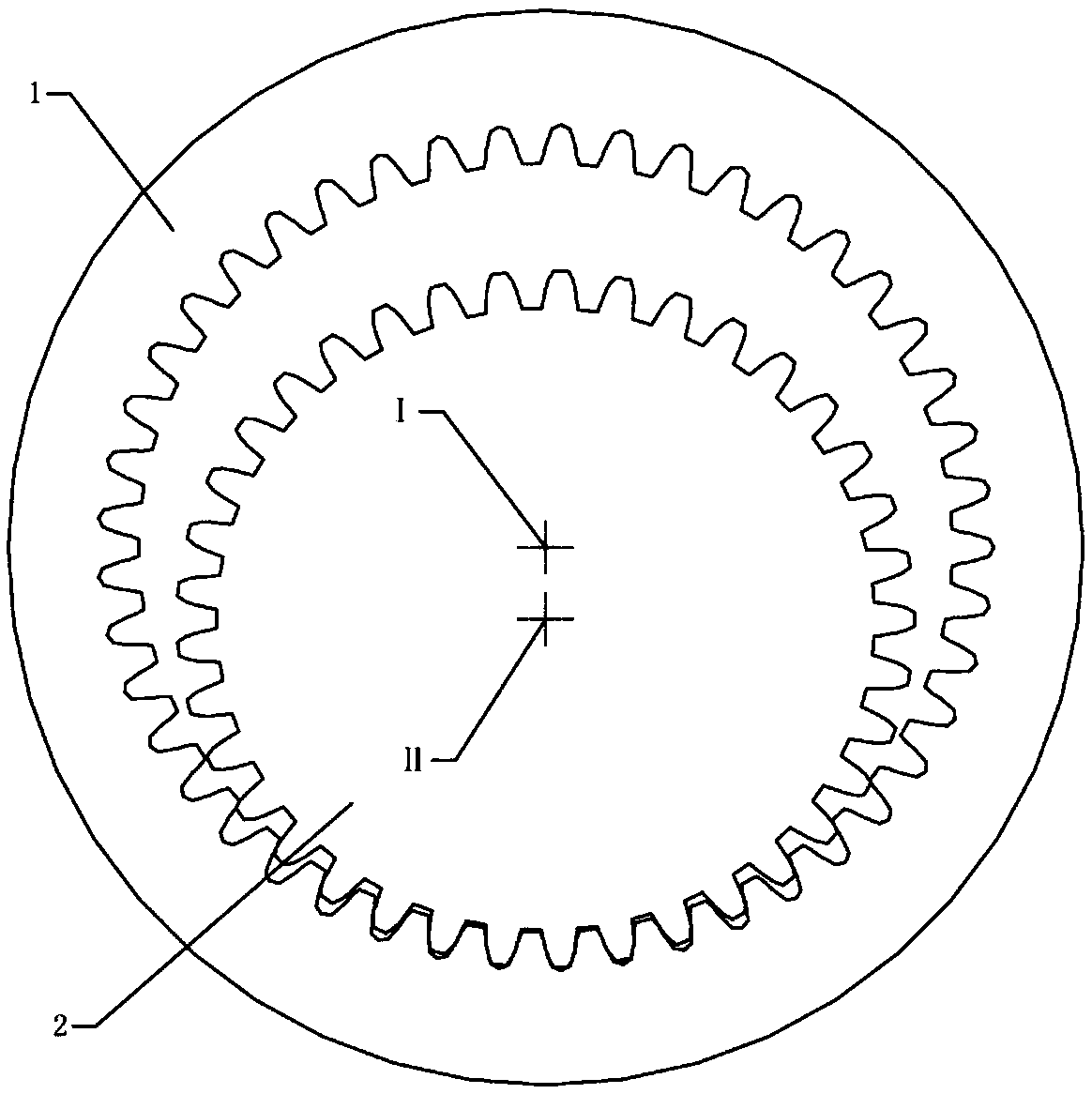

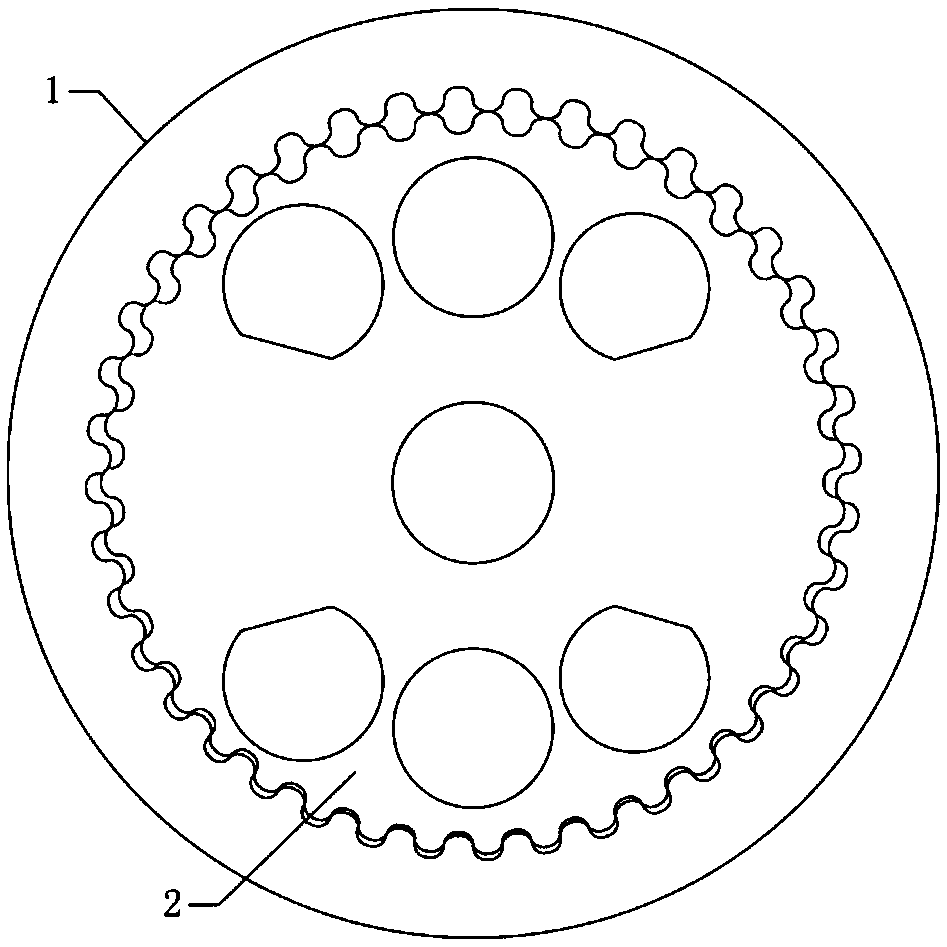

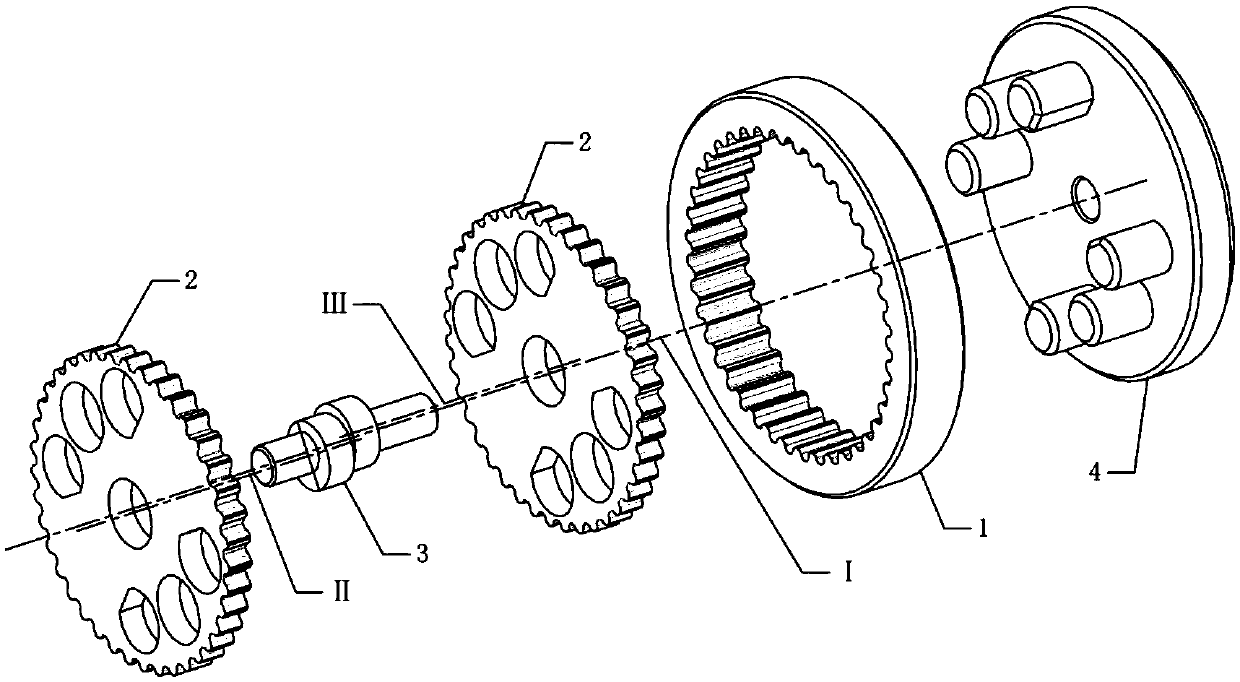

High-contact-ratio internal-gearing cycloidal gear mechanism

InactiveCN105508521AImprove carrying capacitySimple structurePortable liftingToothed gearingsCarrying capacityGear wheel

The invention discloses a high-contact-ratio internal-meshing cycloidal gear mechanism which is composed of a cycloidal internal gear and a cycloidal external gear, wherein the cycloidal external gear is arranged in the cycloidal internal gear and meshes with the cycloidal internal gear; the meshing line of the cycloidal internal gear and cycloidal external gear is a circular arc; assuming that the circular arc radius of the meshing line is r, the pitch radius of the cycloidal internal gear is r1 and the pitch radius of the cycloidal external gear is r2, r1>r>r2; and when the meshing line respectively rolls around the pitch circle of the cycloidal internal gear and the pitch circle of the cycloidal external gear, one point on the meshing line respectively produces two gear tooth apical tooth profiles. A plurality of pairs of teeth simultaneously participate in the meshing in the transmission process, and the pressure angle is small, so that the carrying capacity of the mechanism is greatly enhanced. The tooth root part of the gear basically does not participate in meshing, the tooth profiles can be flexibly designed according to the structural requirements, thereby avoiding the problems of undercut and the like. The high-contact-ratio internal-meshing cycloidal gear mechanism has the advantages of simple structure and fewer parts; and the manufacturing technique is easy to implement.

Owner:贾萌

External medicine patch for treating respiratory tract inflammation, and preparation method of external medicine patch

InactiveCN105434514ANo side effectsReasonable formulaHeavy metal active ingredientsHydroxy compound active ingredientsSide effectMedicine

The invention discloses an external medicine patch for treating respiratory tract inflammation, and a preparation method of the external medicine patch. The external medicine patch is prepared by adopting fructus xanthil, ligusticum wallichii, radix isatidis, radix glycyrrhizae and angelica dahurica as main materials, adopting borneol, cinnabar and natural honey as auxiliary materials, and performing procedures of sterilization, drying, pulverizing, stirring, subpackage, sterilization, cooling and the like. The external medicine patch can effectively treat respiratory tract inflammation such as amygdalitis, faucitis, lymphadenitis and chronic and acute bronchitis, and is economical and free of side effects.

Owner:袁诗辉

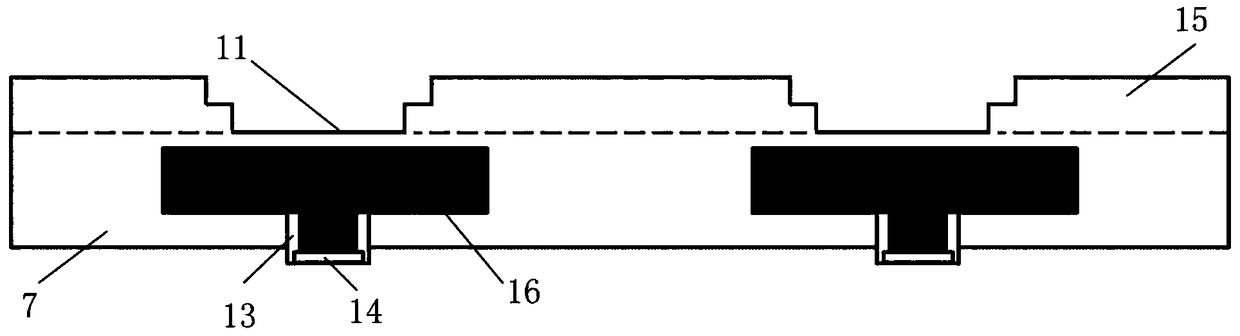

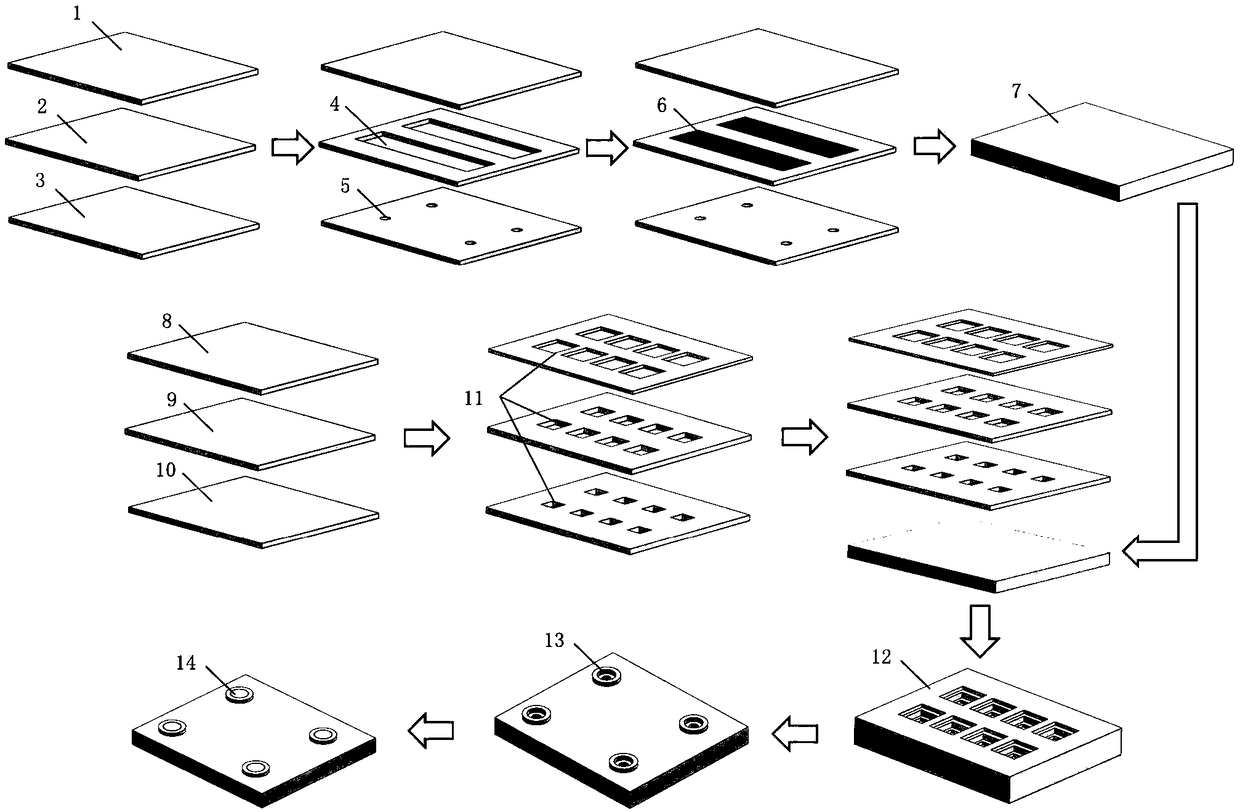

Preparation method of high thermal conductivity phase change temperature control composite packaging substrate

InactiveCN108831837AHighly integratedLow dielectric constantSemiconductor/solid-state device detailsSolid-state devicesComposite substrateAlloy

The invention discloses a preparation method of a high thermal conductivity phase change temperature control composite packaging substrate, wherein, a low-melting-point alloy solid phase change material is integrated directly into an LTCC-ALN composite substrate and a phase change temperature control device with high integration and high thermal conductivity is formed. The invention is realized bythe following technical scheme: a phase change temperature control cavity is produced on the middle AlN green ceramic plate of the multi-layer AlN green ceramic plate, and then the aluminum nitride AlN substrate embedded with the sandwich of the phase change temperature control cavity is formed by laminated isostatic pressing and co-firing; matrix-distributed electronic component mounting cavities are fabricated on the LTCC green ceramic substrate, and then the AlN substrate and the LTCC green ceramic substrate are laminated and co-fired to form the LTCC-AlN composite substrate in which an electronic active device can be embedded. At last, solid phase change material of the low melting point alloy is heated and melted into the liquid state and poured into the phase change temperature control cavity of the composite substrate, and the phase change temperature control composite substrate with high thermal conductivity is prepared by sealing a cover plate.

Owner:10TH RES INST OF CETC

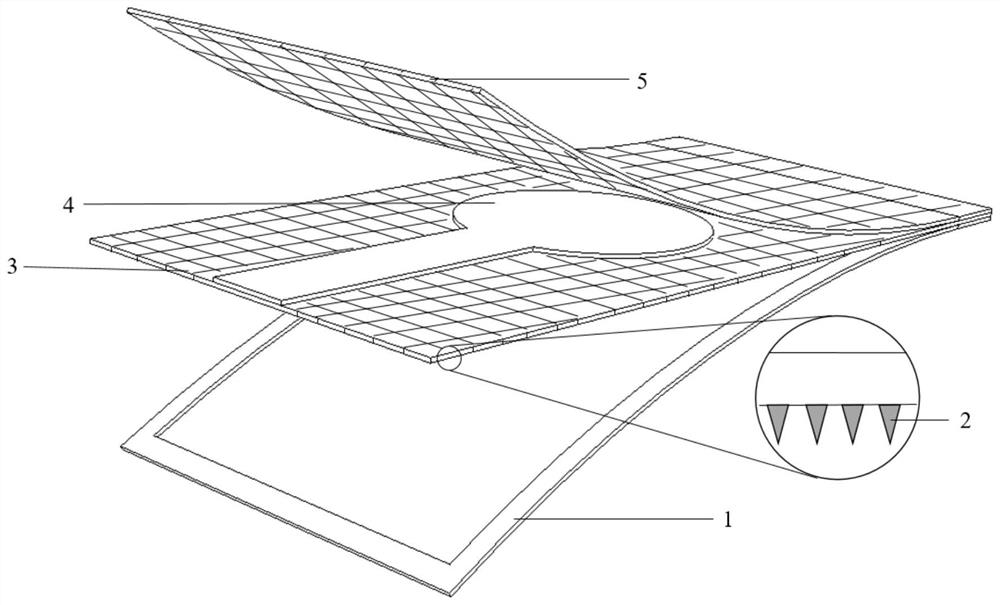

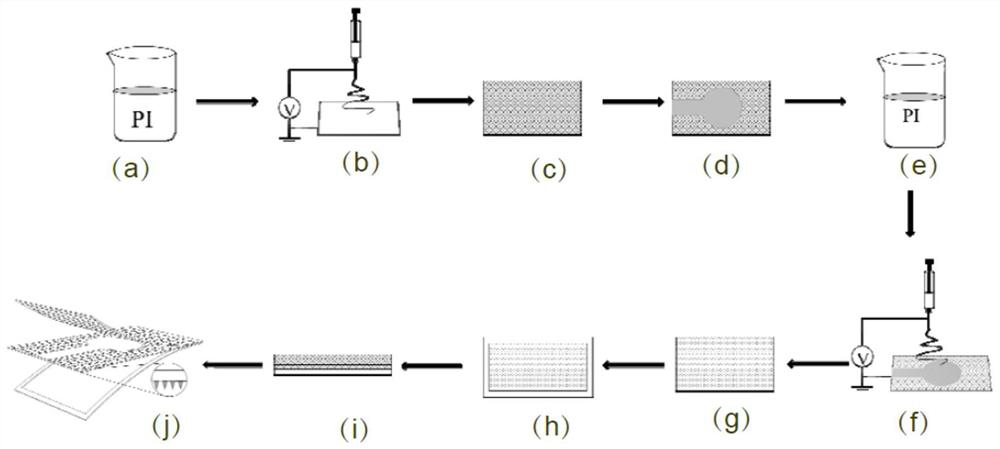

High-permeability friction nano sensor and preparation method thereof

ActiveCN113197546AAchieve Stable AdhesionAchieve self-adhesive functionDiagnostic recording/measuringMonocomponent synthetic polymer artificial filamentEngineeringWearable Electronic Device

The invention belongs to the related technical field of flexible wearable electronic devices, and discloses a high-permeability friction nano sensor and a preparation method thereof. The nano sensor comprises a packaging layer, an electrode layer, a friction layer and a microstructure layer which are arranged from top to bottom, wherein the friction layer is made of PI and is prepared by adopting a one-step electrostatic spinning process; the friction nanometer sensor further comprises an adhesion layer, the adhesion layer is arranged on the microstructure layer, and adhesion between the friction nano sensor and a user is achieved through wetting. The friction nano sensor is convenient to wear, when the sensor is worn, stable adhesion of a device can be achieved by wetting the adhesion layer with a small amount of water, a transparent adhesive tape or a double-faced adhesive tape does not need to be used for assisting in wearing, and the self-adhesion function of the device is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Polyformaldehyde composite material and preparation method thereof

The invention relates to a polyformaldehyde composite material and a preparation method thereof. The preparation method comprises the following steps: respectively uniformly stirring nanometer aluminum oxide, micron aluminum oxide and 2wt%-3wt% of coupling agent, treating the surfaces of nanometer aluminum oxide and micron aluminum oxide, and then drying after treating; preparing 0.3-1 part by weight of sulfonated graphene into a sulfonated graphene aqueous solution; dispersing 3-10 parts by weight of nanometer aluminum oxide treated with the coupling agent into deionized water, dropwise adding the sulfonated graphene solution into a nanometer aluminum oxide dispersion liquid under stirring state, stopping stirring after the ending of dropwise adding, filtering after the layering of liquid, and drying filter residue, thereby acquiring a sulfonated graphene / nanometer aluminum oxide compound; mixing 80-93 parts by weight of polyformaldehyde, 3-7 parts by weight of sulfonated graphene / nanometer aluminum oxide compound, parts by 3.5-9 weight of micron aluminum oxide treated with the coupling agent and a defined amount of additives, and then drying; mixing for 3-4 hours in a blender mixer; extruding, chopping and drying after mixing, thereby acquiring the polyformaldehyde composite material.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

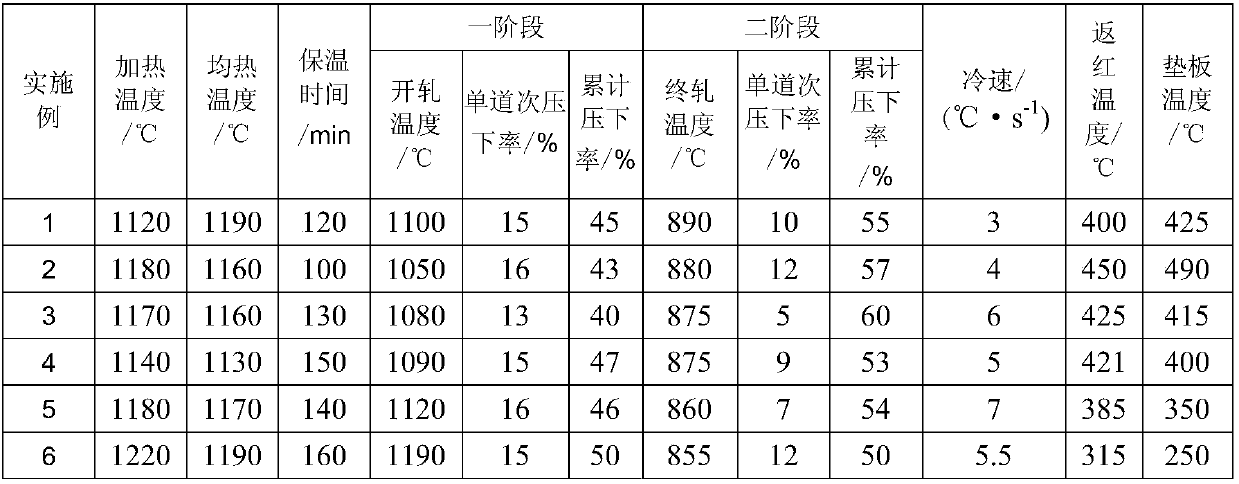

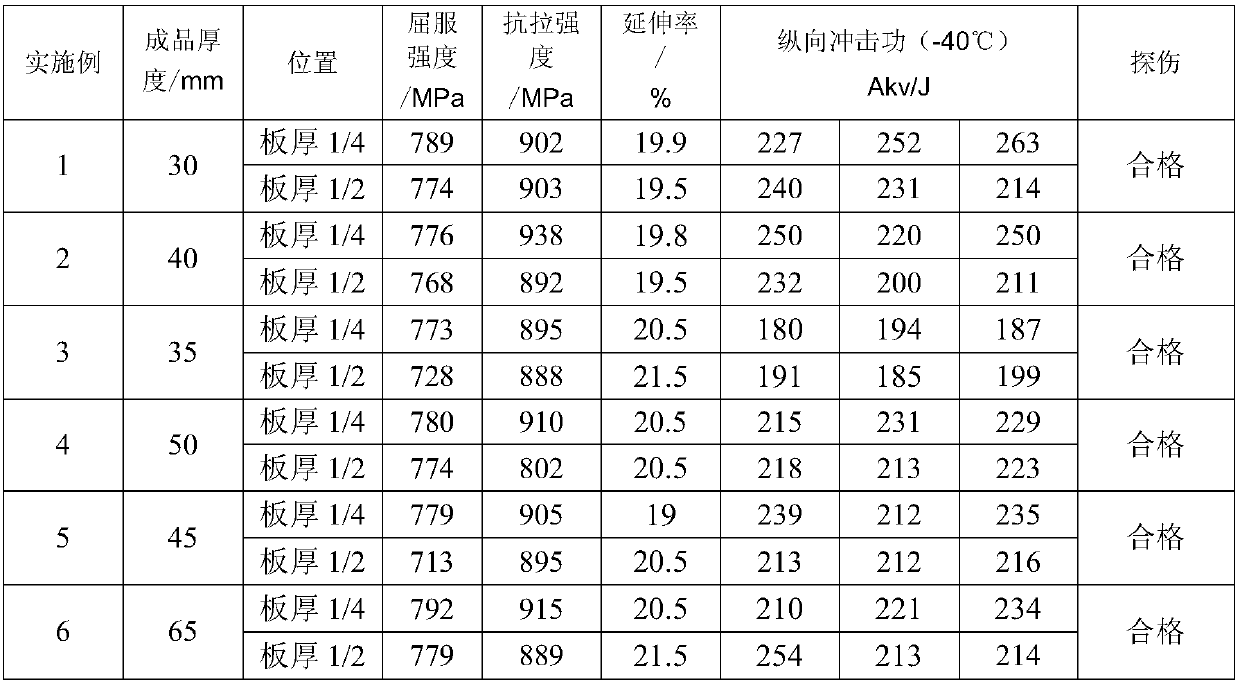

High-manganese medium-thickness steel plate for ocean engineering and production method thereof

The invention discloses a high-manganese medium-thickness steel plate for ocean engineering and a production method thereof. The steel contains 0.05%-0.25% of C, 5.0%-9.0% of Mn, 0.20%-0.50% of Si, 0.10%-0.50% of Cu, 0.25%-0.40% of Ni, 0.30%-0.90% of Cr, 0.25%-0.80% of Mo, 0.001%-0.007% of N, smaller than or equal to 0.01% of P, smaller than or equal to 0.01% of S, 0.01%-0.05% of Al and the balance of Fe and inevitable impurities. The heating temperature is 1140 to 1220 DEG C. The first-stage initial rolling temperature is greater than or equal to 1000 DEG C. The single-pass reduction rate isgreater than 13%. The cumulative reduction rate is 40%-50%. The second-stage final rolling temperature is 850-900 DEG C. The single-pass reduction rate is 5%-12%. The cumulative reduction rate is 50%-60%. The cooling speed is 3-7 DEG C / s. The re-reddening temperature is 300-450 DEG C and the hardening and tempering treatment is conducted finally. The thickness of the steel plate is 30-65mm. The steel plate is excellent in low-temperature toughness, and no cold crack exists on the surface of the steel plate after rolling.

Owner:ANGANG STEEL CO LTD

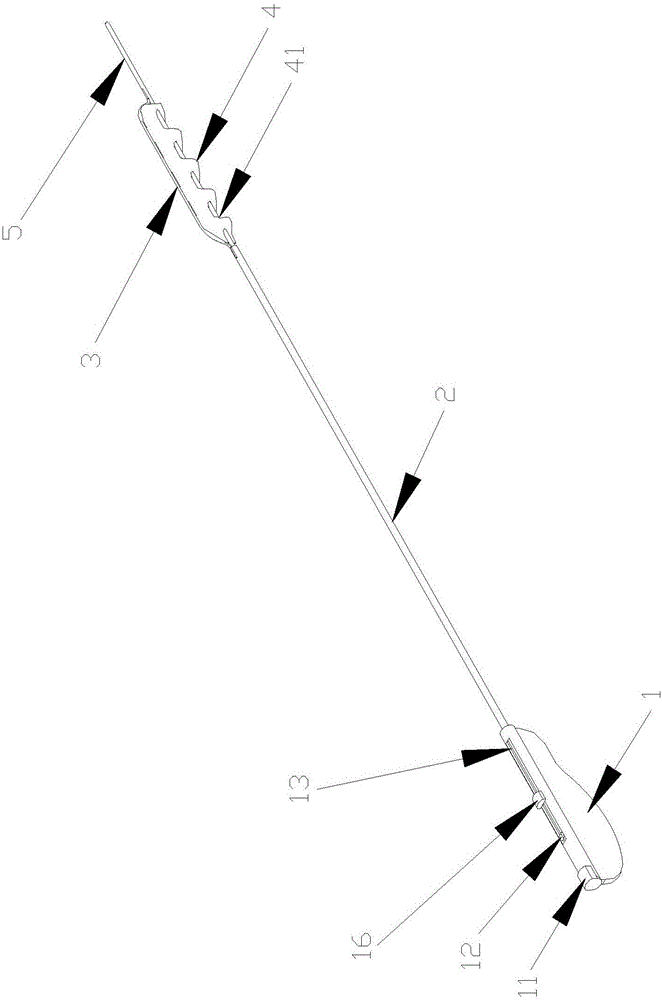

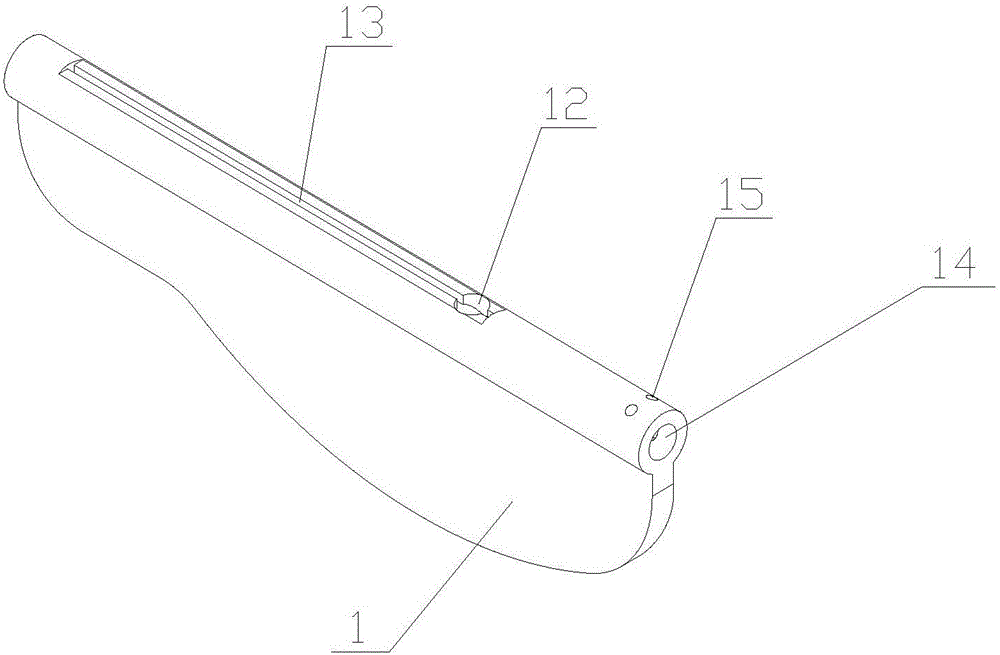

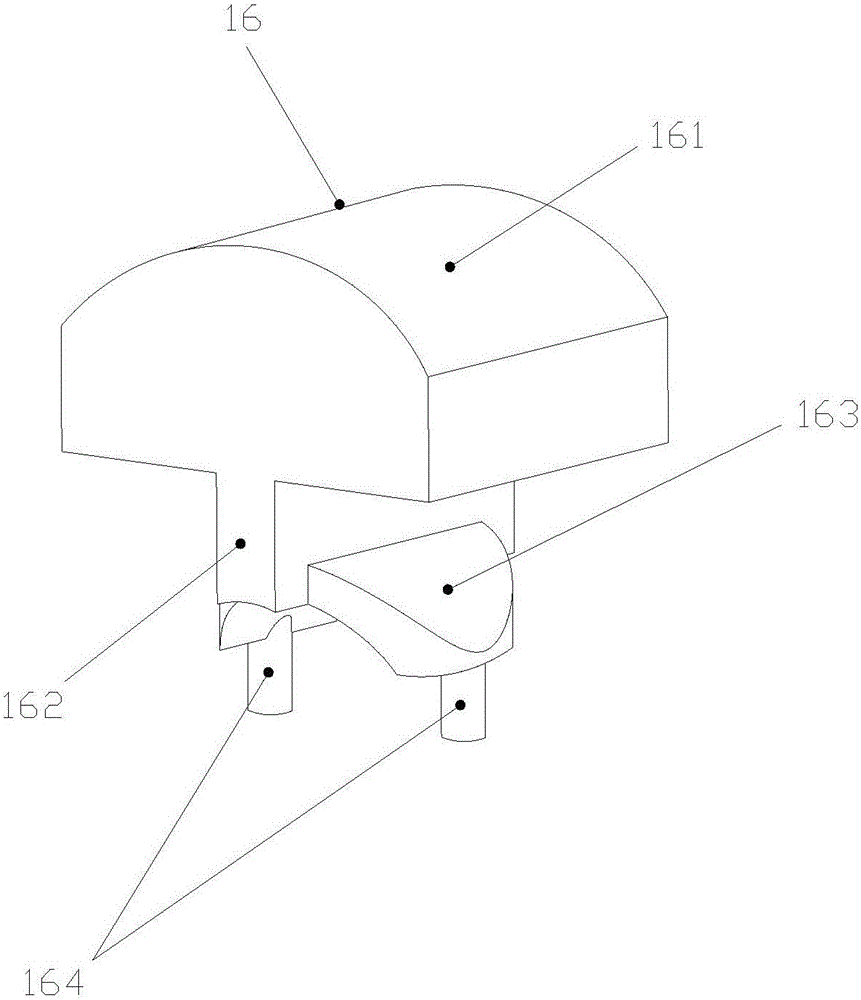

Diaphragm type body cavity blocking equipment

ActiveCN105748127ADoes not cause body cavity wall damageEasy to put inOcculdersEngineeringBody cavity

The invention relates to diaphragm type body cavity blocking equipment which is provided with a handle, a tuba handle, a shaping wire, a film and an inner core; the two ends of the shaping wire are fixed to the far end of the tube handle and the inner core respectively; the shape of the film in the preparation state is that one or more edges are in a linear shape, and other edges are a polygon composed of straight lines or curves, an axially symmetric figure or a face in an irregular shape, one edge, in the linear shape, on the film is provided with a plurality of through holes in the sideline direction, the inner core penetrates through the through holes, the other side edge opposite to the linear-shaped edge of the film wraps and is fixed to the shaping wire, and the position between the shaping wire and the inner core is in a spiral shape under the use state of the film.The shape of a blocking object of the diaphragm type body cavity blocking equipment can be controlled precisely, the blocking object is placed into a body cavity conveniently, completely blocking and one-time taking out of foreign matter can be achieved, and various situations in the operation process can be coped with flexibly.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

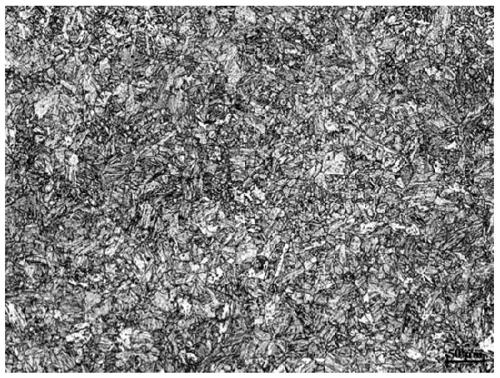

Ultrahigh-strength steel with fatigue limit larger than 600 MPa for ocean engineering and preparation method thereof

ActiveCN113073263AHigh strengthGuaranteed SolderabilityFurnace typesHeat treatment furnacesTemperingUltimate tensile strength

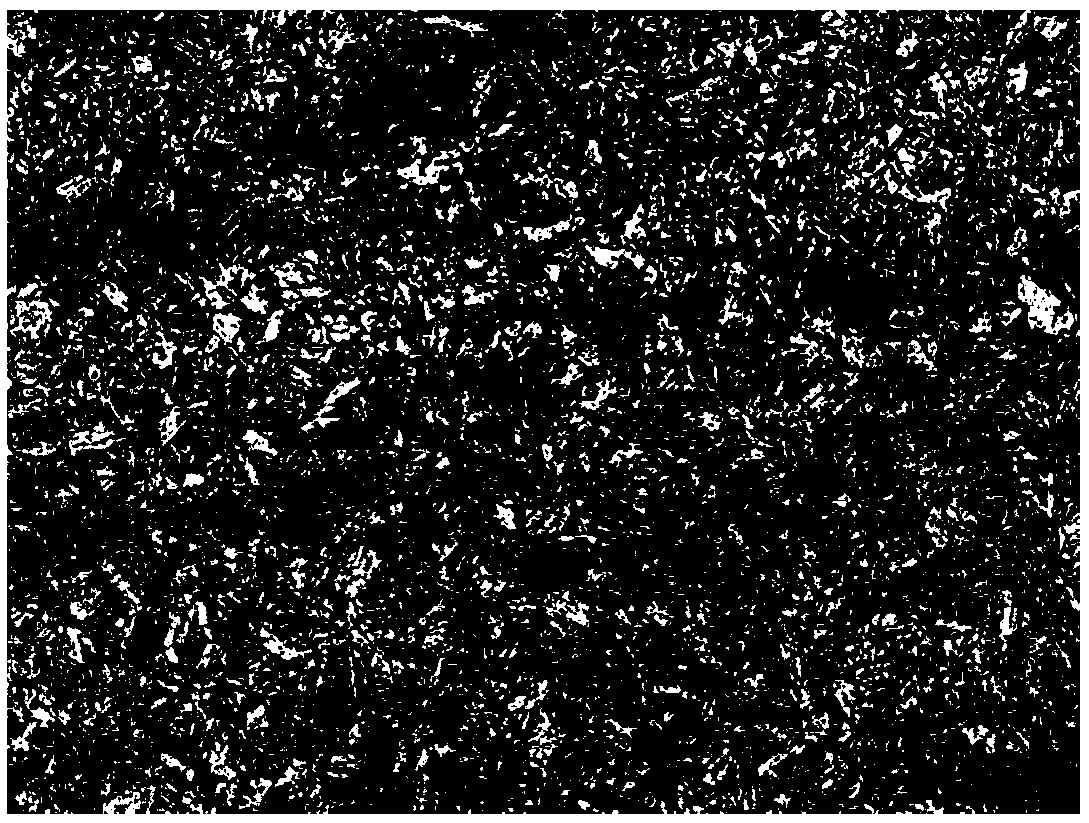

The invention belongs to the field of preparation of steel and iron materials, and discloses ultrahigh-strength steel with the fatigue limit larger than 600 MPa for ocean engineering and a preparation method thereof. The ultrahigh-strength steel comprises the chemical components in percentage by weight: 0.08-0.11% of C, 0.20-0.50% of Si, 0.70-1.00% of Mn, 6.00-8.00% of Ni, 0.50-0.70% of Cr, 0.80-0.90% of Mo, 0.05-0.08% of V, less than or equal to 0.003% of P, less than or equal to 0.001% of S and the balance Fe and inevitable impurities. According to the steel plate manufacturing method of the ultrahigh-strength steel, a controlled rolling process is adopted, then a steel plate is subjected to a quenching and tempering heat treatment process, the yield strength of the steel plate is larger than or equal to 1000 MPa, the fatigue limit is larger than or equal to 600 MPa, and the impact energy at the temperature of -80 DEG C is larger than or equal to 100 J; and the microstructure of the steel plate is tempered martensite and VC precipitated phase.

Owner:NORTHEASTERN UNIV

Magnesium alloy surface corrosion-resistant super-hydrophobic film layer and preparation method and application thereof

PendingCN113073322AEasy to handleEasy to manufactureMetallic material coating processesSurface corrosionCorrosion resistant

The invention discloses a magnesium alloy surface corrosion-resistant super-hydrophobic film layer and a preparation method and application thereof. The preparation method comprises the following steps of forming a layered double-metal hydroxide film with a micro-nano structure on the surface of a substrate by adopting a hydrothermal method; and carrying out hydrophobization treatment on the obtained layered double-metal hydroxide film so as to obtain the magnesium alloy surface corrosion-resistant super-hydrophobic film layer. According to the preparation method of the magnesium alloy surface corrosion-resistant super-hydrophobic film layer, preparation can be directly conducted on the magnesium alloy, the treatment process is simple, preparation is convenient, the period is short, and the preparation technology is easy to achieve and environmentally friendly. Meanwhile, the magnesium alloy surface corrosion-resistant super-hydrophobic film layer prepared through the method has good hydrophobic performance, the corrosion resistance of the magnesium alloy can be remarkably improved, and good corrosion resistance can be kept for a long time. The invention provides a corrosion-resistant mechanism of the prepared corrosion-resistant film layer, and the corrosion-resistant film layer has wide application prospects in the fields of batteries, automobile industry or aerospace.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com