Magnesium alloy surface corrosion-resistant super-hydrophobic film layer and preparation method and application thereof

A magnesium alloy and super-hydrophobic technology, applied in the coating process of metal materials, coatings, etc., can solve problems such as complex processes and no anti-corrosion mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

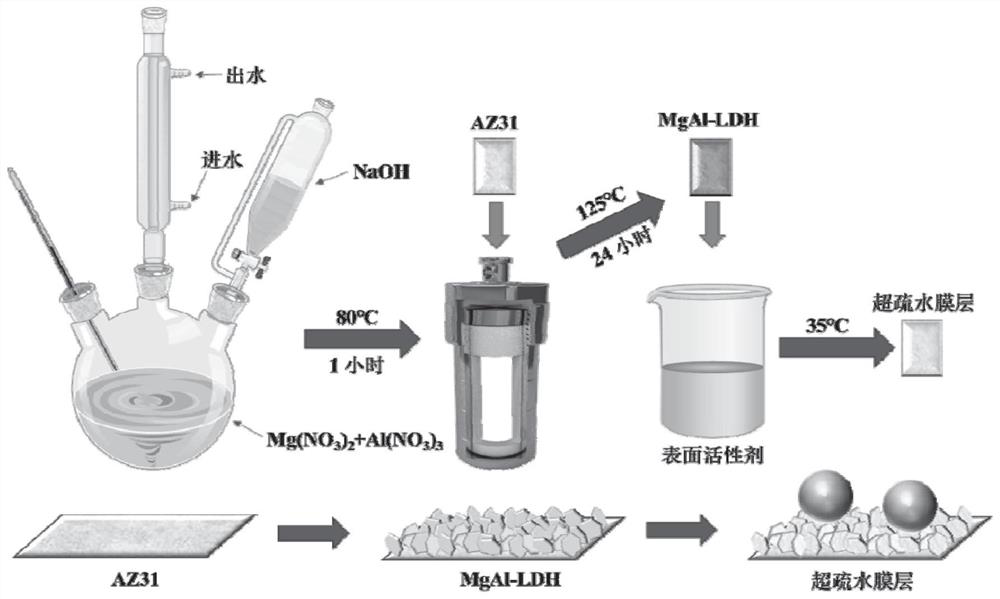

[0028] An aspect of the embodiments of the present invention provides a method for preparing a corrosion-resistant super-hydrophobic film on the surface of a magnesium alloy, which includes:

[0029] Provide magnesium alloy as a substrate;

[0030] A layered double metal hydroxide film (MgAl-LDH film) with a micro-nano structure is formed on the surface of the substrate by a hydrothermal method, and the metal elements in the layered double metal hydroxide film include Al and Mg;

[0031] And, hydrophobizing treatment is performed on the obtained layered double metal hydroxide film, so as to prepare a corrosion-resistant super-hydrophobic film layer on the surface of the magnesium alloy.

[0032] In some more specific embodiments, the preparation method includes:

[0033] Disperse magnesium salt and aluminum salt in water to form a solution, then adjust the pH of the solution to 10-12, then add carbonate, and react at 70-90°C for 1-2 hours to obtain a magnesium-aluminum suspen...

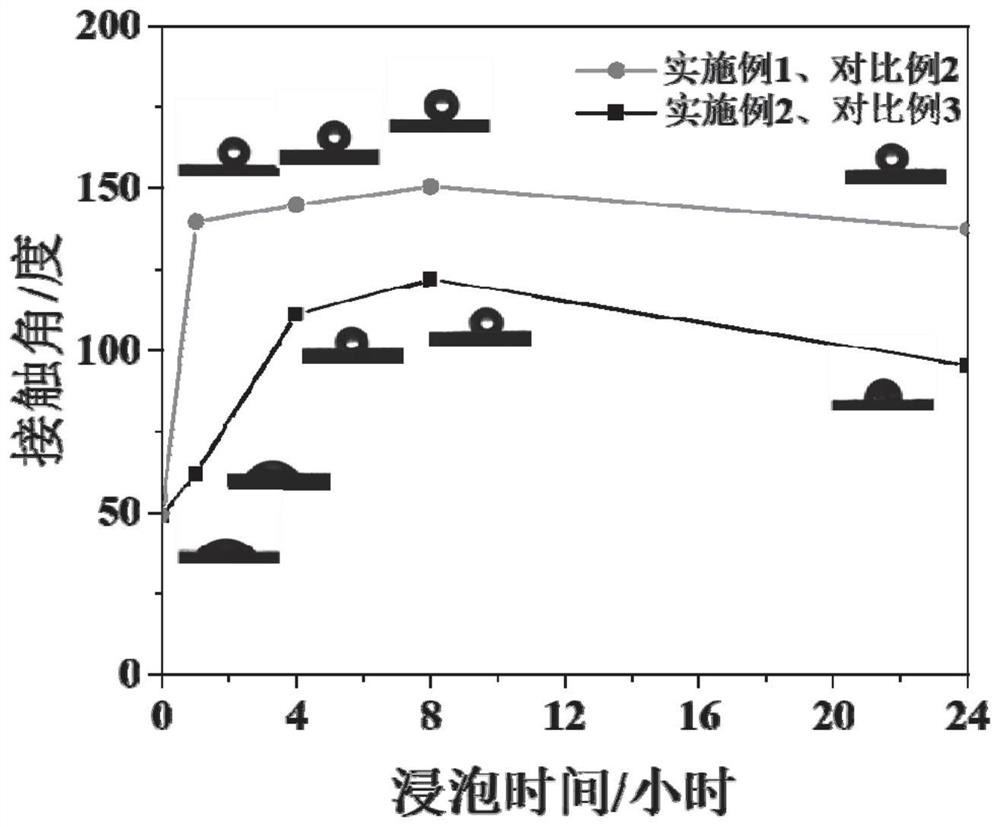

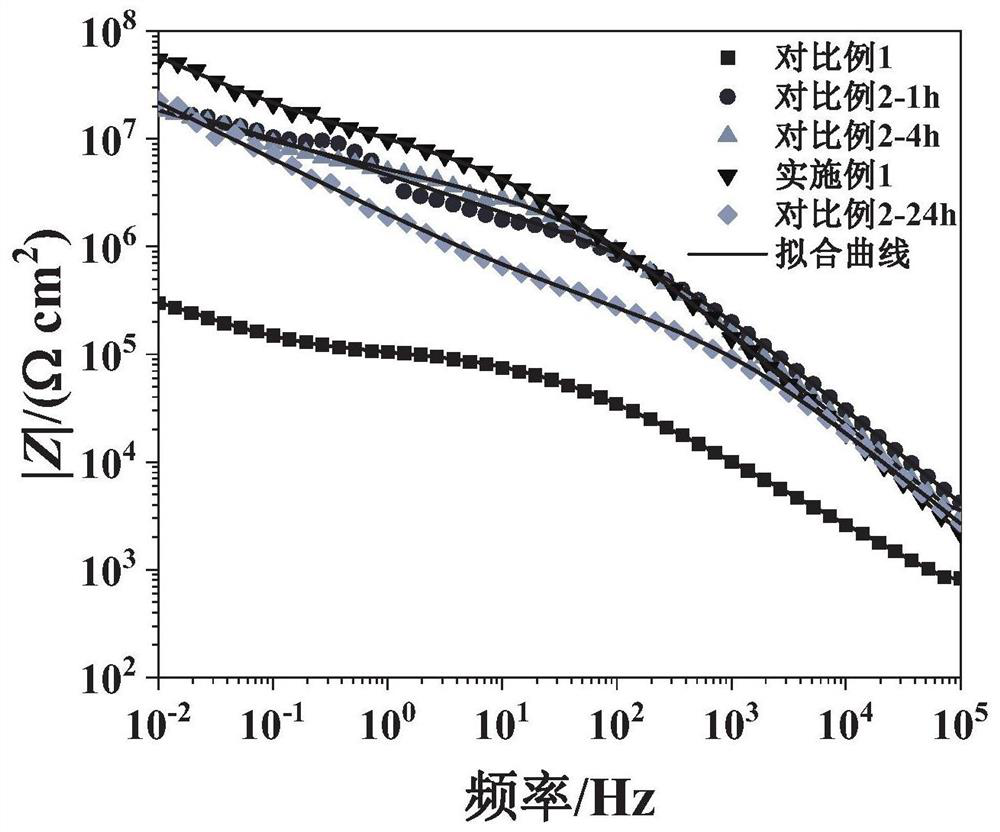

Embodiment 1

[0075] (1) Use 400#, 800#, 1200#, 1500# SiC sandpaper to polish the surface of the magnesium alloy sample, then ultrasonically clean it in absolute ethanol for 10 minutes, and then dry it naturally in the air. / L of NaOH solution for 60s to remove the oxide layer on the surface, and then dry under atmospheric conditions;

[0076] (2) Synthesis of MgAl-LDH film:

[0077] 4.608g Mg(NO 3 ) 2 ·6H 2 O, 2.25g Al(NO 3 ) 3 9H 2 O was dispersed in deionized water and magnetically stirred under hydrothermal conditions, then 0.2 mol / L NaOH solution was added dropwise until the pH of the solution was 12, and then 0.318 g of NaOH was added 2 CO 3 , add deionized water to 300ml in the whole system, and place it in an oil bath at 80°C for 1h, then place it together with the magnesium alloy sample treated in step (1) in an autoclave for hydrothermal reaction (react at 130°C for 18h ); Finally, the prepared sample was taken out and rinsed with deionized water, and then dried at 65° C. ...

Embodiment 2

[0082] (1) Use 400#, 800#, 1200#, 1500# SiC sandpaper to polish the surface of the magnesium alloy sample, then ultrasonically clean it in absolute ethanol for 10 minutes, and then dry it naturally in the air. / L of NaOH solution for 60s to remove the oxide layer on the surface, and then dry under atmospheric conditions;

[0083] (2) Synthesis of MgAl-LDH film:

[0084] 4.608g Mg(NO 3 ) 2 ·6H 2 O, 2.25g Al(NO 3 ) 3 9H 2 O was dispersed in deionized water and magnetically stirred under hydrothermal conditions, then 0.2 mol / L NaOH solution was added dropwise until the pH of the solution was 12, and then 0.318 g of NaOH was added 2 CO 3 , add deionized water to 300ml in the whole system, and place it in an oil bath at 80°C for 1h, then place it together with the magnesium alloy sample treated in step (1) in an autoclave for hydrothermal reaction (react at 130°C for 18h ); Finally, the prepared sample was taken out and rinsed with deionized water, and then dried at 65° C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impedance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com