Method for preparing superhydrophobic film on magnesium alloy surface

A magnesium alloy, super-hydrophobic technology, which is applied to the device for coating liquid on the surface, the pretreatment surface, the coating process of metal materials, etc., can solve the problems of complex preparation process, operator and environmental hazards, and achieve simple processing , improve the corrosion resistance, the preparation process is easy to achieve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

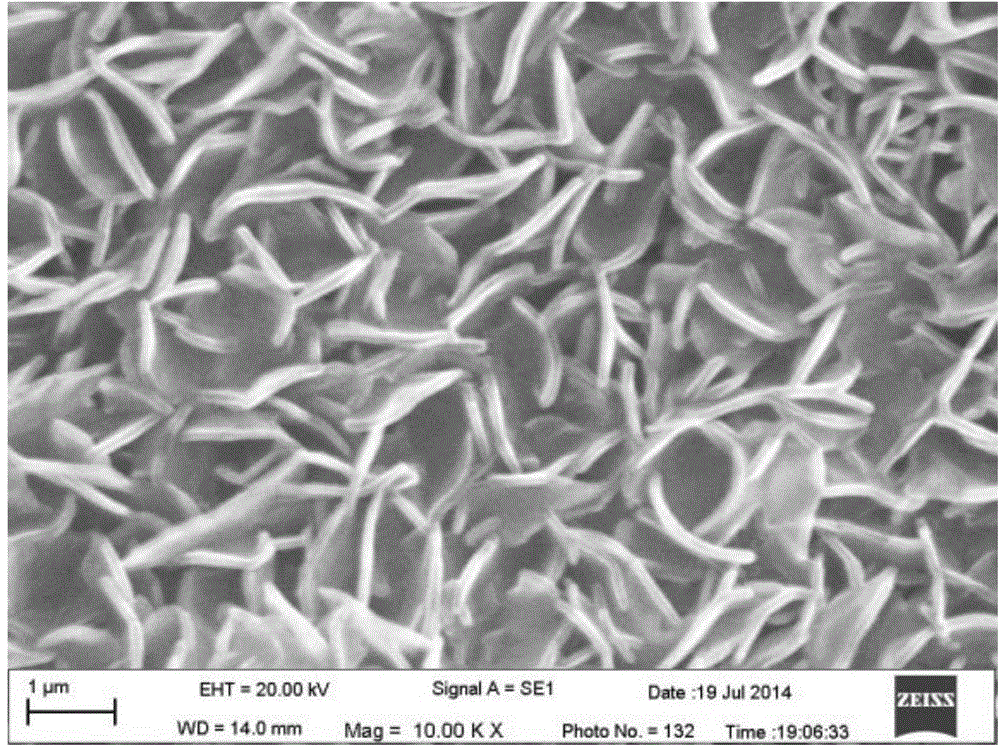

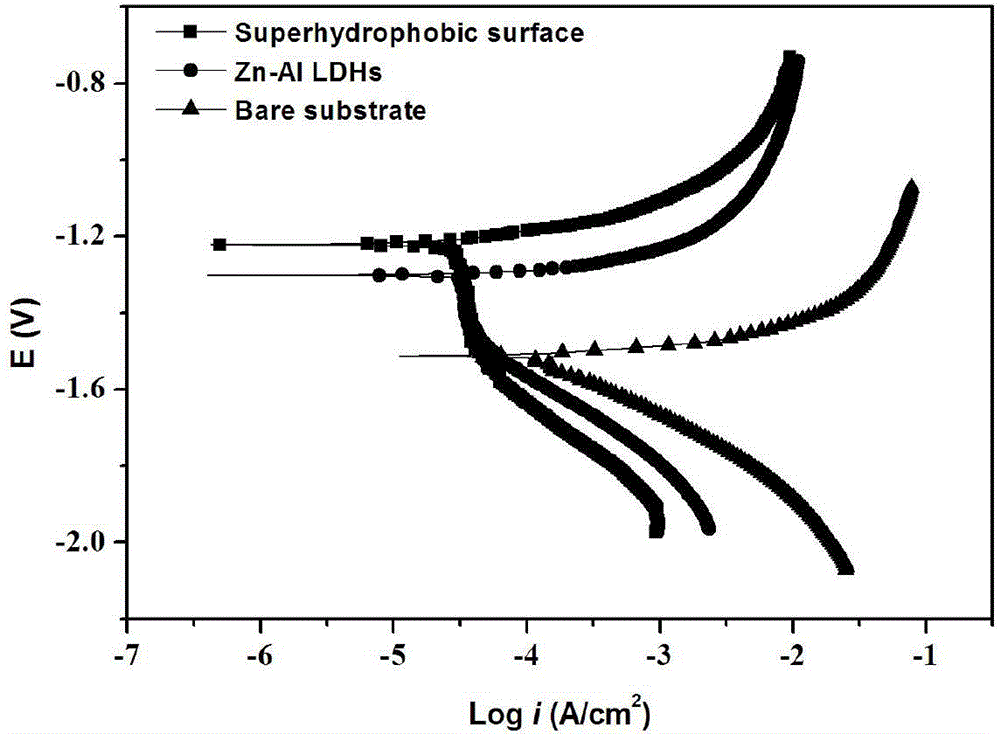

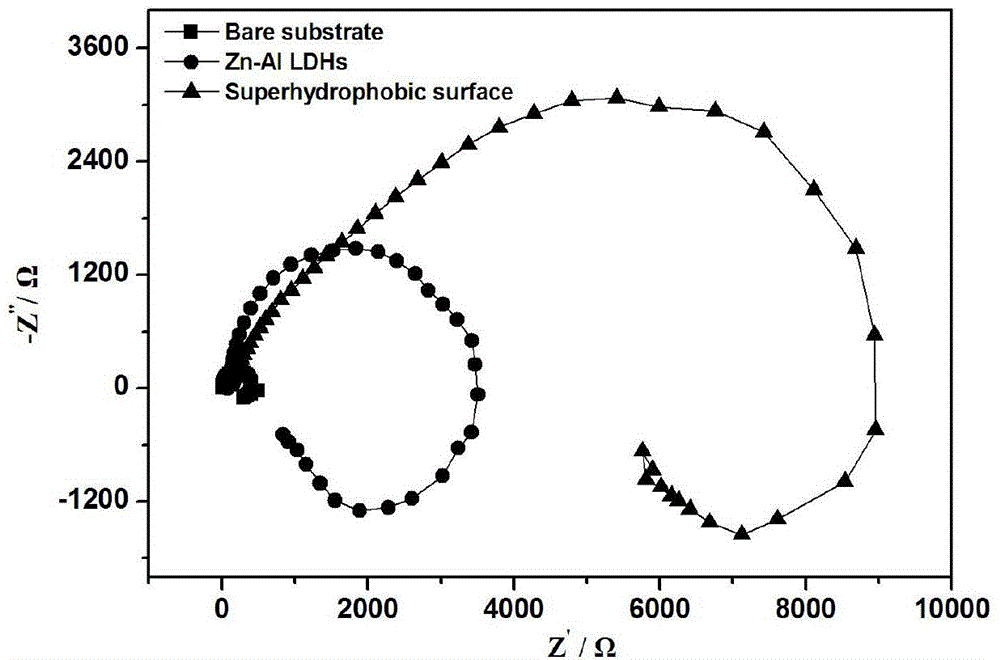

[0025] The material is AZ91 magnesium alloy plate, which is put into the pre-prepared solution after surface treatment, and a layer of hydrotalcite-like rough surface with micro / nano multi-level structure is grown on the surface of the magnesium alloy by hydrothermal method, and then after low surface free It can be modified to obtain a super-hydrophobic surface, specifically including the following steps and process conditions:

[0026] (1) Surface pretreatment of AZ91 magnesium alloy: use 400, 800, and 1500 mesh SiC sandpaper to polish the magnesium alloy substrate in sequence to remove oxides and burrs on the surface of the magnesium alloy; rinse the surface of the polished magnesium alloy sample with deionized water, and Put the rinsed magnesium alloy sample in acetone and ultrasonically clean it for 15 minutes, take it out, clean it with absolute ethanol, dry the surface of the sample with a hair dryer, and put it in a drying dish for use.

[0027] (2) Preparation of reac...

Embodiment 2

[0032] Embodiment 2 The method for preparing a superhydrophobic film layer on the surface of a magnesium alloy is basically the same as that of Embodiment 1, except that the pH=10 of the solution in step (2) is changed to pH=10.5, and the modification of the low surface free energy in step (4) The time of the modification was changed to 4 hours, and the temperature was room temperature. After the modification, it was cleaned with absolute ethanol, and after drying with a hair dryer, a super-hydrophobic film layer was obtained on the surface of the magnesium alloy.

Embodiment 3

[0034] Embodiment three prepares the method for superhydrophobic film layer on the surface of magnesium alloy and embodiment one is basically the same, and difference is: the pH=10 of step (2) solution changes pH=11, and the constant temperature water bath in step (3) The temperature was set at 70°C, the time for low surface free energy modification in step (4) was changed to 3 hours, and the temperature was room temperature. After the modification was completed, it was cleaned with absolute ethanol and dried with a hair dryer to obtain a superhydrophobic film on the surface of the magnesium alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com