Linkage membrane capacitive pressure sensitive chip and manufacturing method thereof

A sensitive chip and film capacitor technology, applied in the direction of measuring force, measuring devices, instruments, etc., can solve the problems of limiting sensor performance, small relative change in capacitance, and small measuring range, so as to increase the measuring range, improve linearity, The effect of easy manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

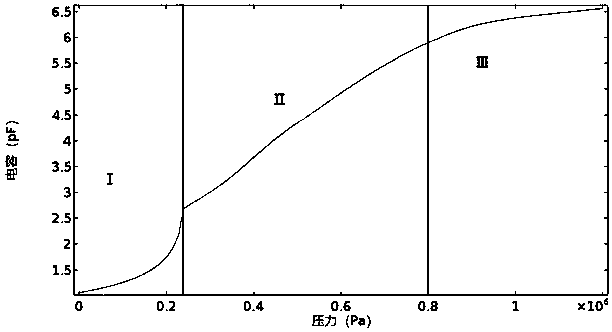

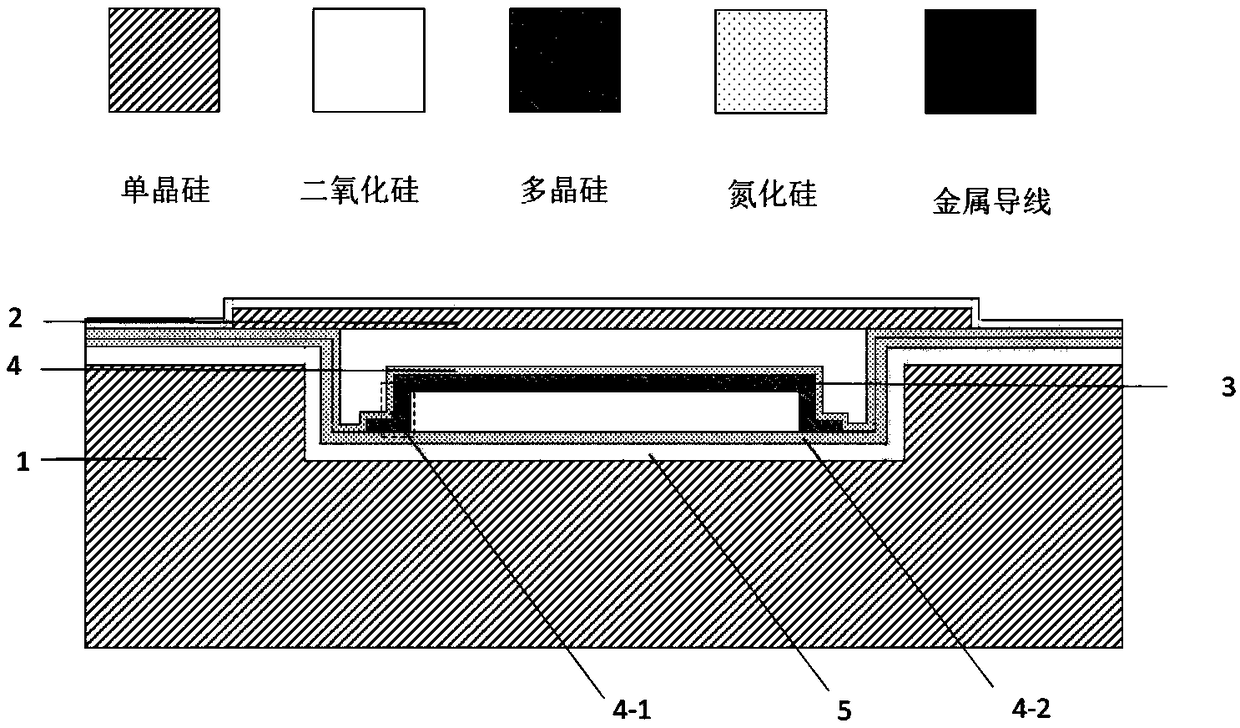

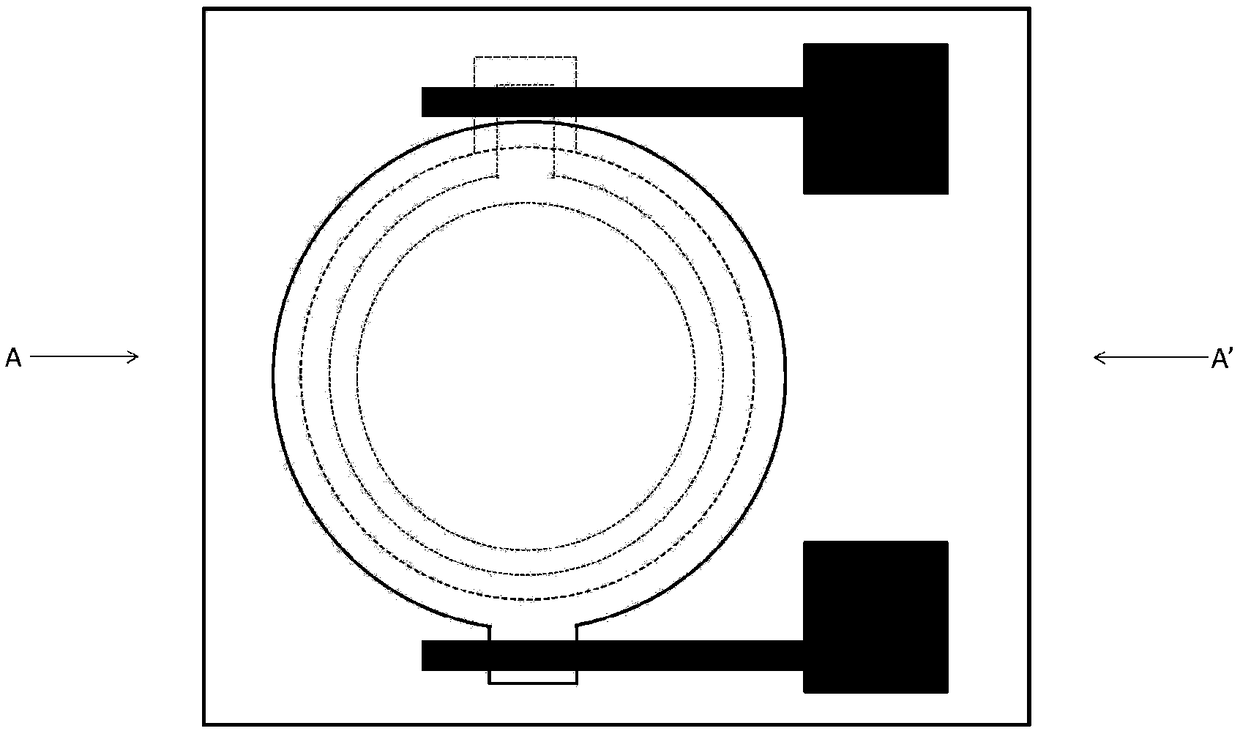

[0098] use figure 1 and figure 2 The linkage membrane capacitive pressure sensitive structure shown is designed to be a pressure sensor with a range of 240kPa to 800kPa, and its structural parameters are as follows:

[0099] The pressure-sensitive diaphragm (upper plate) adopts a circular diaphragm with a radius of 140 μm and a thickness of 6 μm, a radius of the lower plate of 140 μm, a thickness of 10 μm, a suspended height of the lower plate of 2 μm, and a distance between the upper plate and the dielectric layer of 500nm, and the thickness of the silicon nitride dielectric layer is 100nm.

[0100] Performance:

[0101] Under the above structure size, using finite element software for simulation analysis, the relationship curve between output capacitance and pressure is obtained as follows: Figure 18 shown. As the pressure changes, the output of the sensor can be divided into three areas: area Ⅰ, which is a nonlinear area, and the pressure range is 0 to 240kPa; area Ⅱ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com