Acidic corrosion-resistant X65 seamless steel pipeline and manufacturing method thereof

A technology for seamless line pipe and corrosion performance, applied in the field of corrosion-resistant materials and seamless steel pipes, can solve the problem of unrepresented SSC resistance, and achieve improved acid corrosion resistance, uniform grain structure, and good impact toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

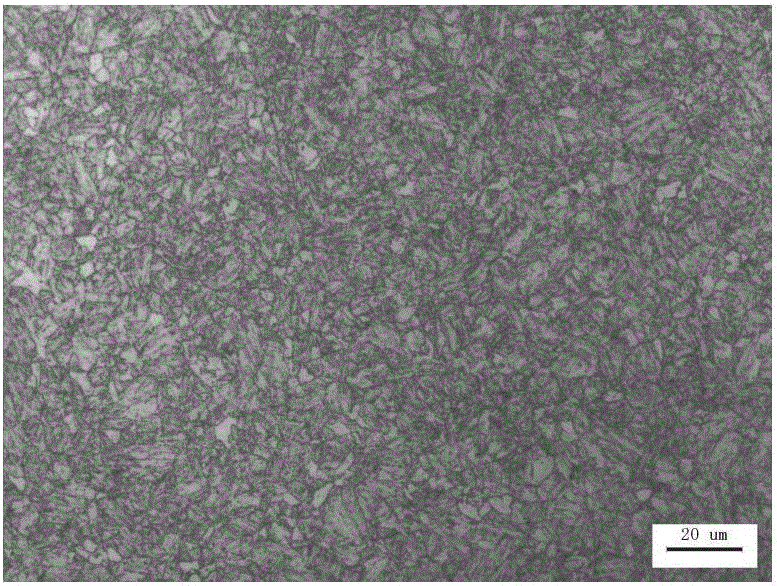

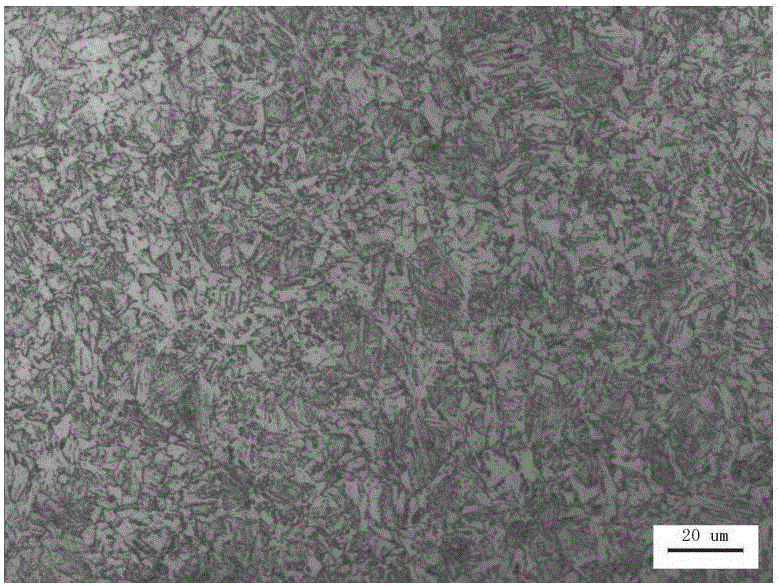

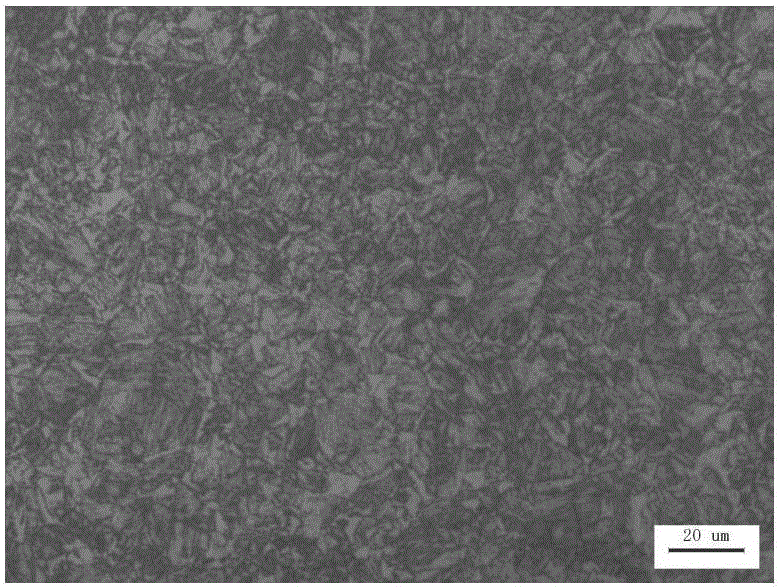

[0029] The following examples are used to specifically illustrate the content of the present invention, and the comparative example is a common 20# steel pipe. The chemical compositions of the examples and comparative examples are shown in Table 1, the rolling and heat treatment methods are shown in Table 2, and the tensile and impact properties are shown in Tables 3 and 4. Example 1 The horizontal Vickers HV10 hardness of the steel pipe was measured at 4 points at the inner, middle and outer positions respectively, and the hardness results are shown in Table 5. The corrosion test is based on the requirements of the API 5L standard, and the HIC is tested by the NACE-0284-2003 standard A solution. It is generally believed that CLR≤15%, CTR≤5%, CSR≤2%, and the anti-HIC performance meets the requirements of the standard. Examples and comparison The HIC performance test results of the ratio are shown in Table 6. SSC corrosion test is according to ASTM G39-99 standard four-point b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com