Method of conducting in-situ growth of hydrotalcite-like membrane on surface of magnesium alloy on basis of electric field regulation and control and hydrotalcite-like membrane

A technology of electric field regulation and in-situ growth, which is applied in electrolytic inorganic material coating, medical science, prosthesis, etc., can solve the problems of expensive and complicated preparation process, and achieve the effect of simple processing process and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

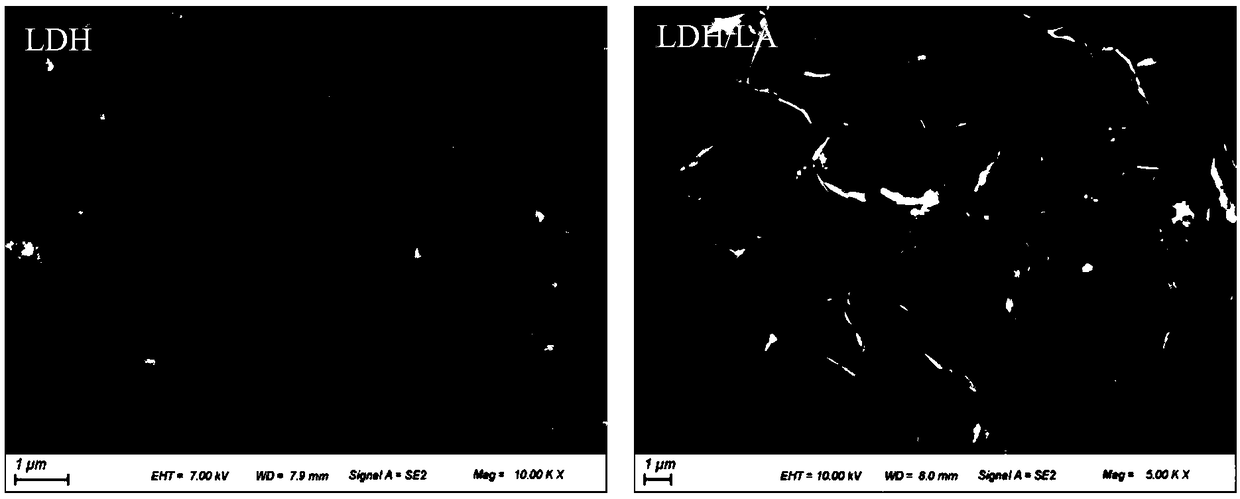

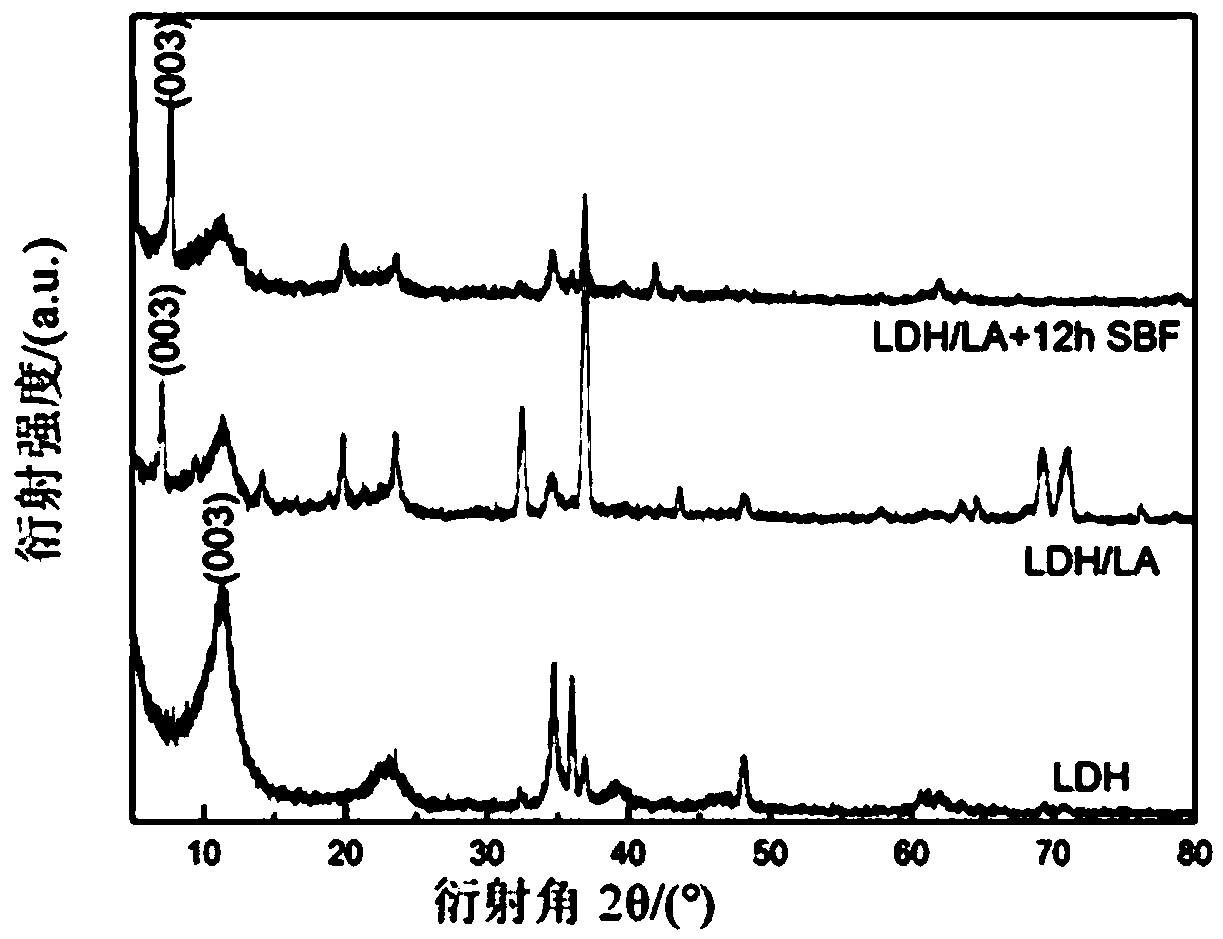

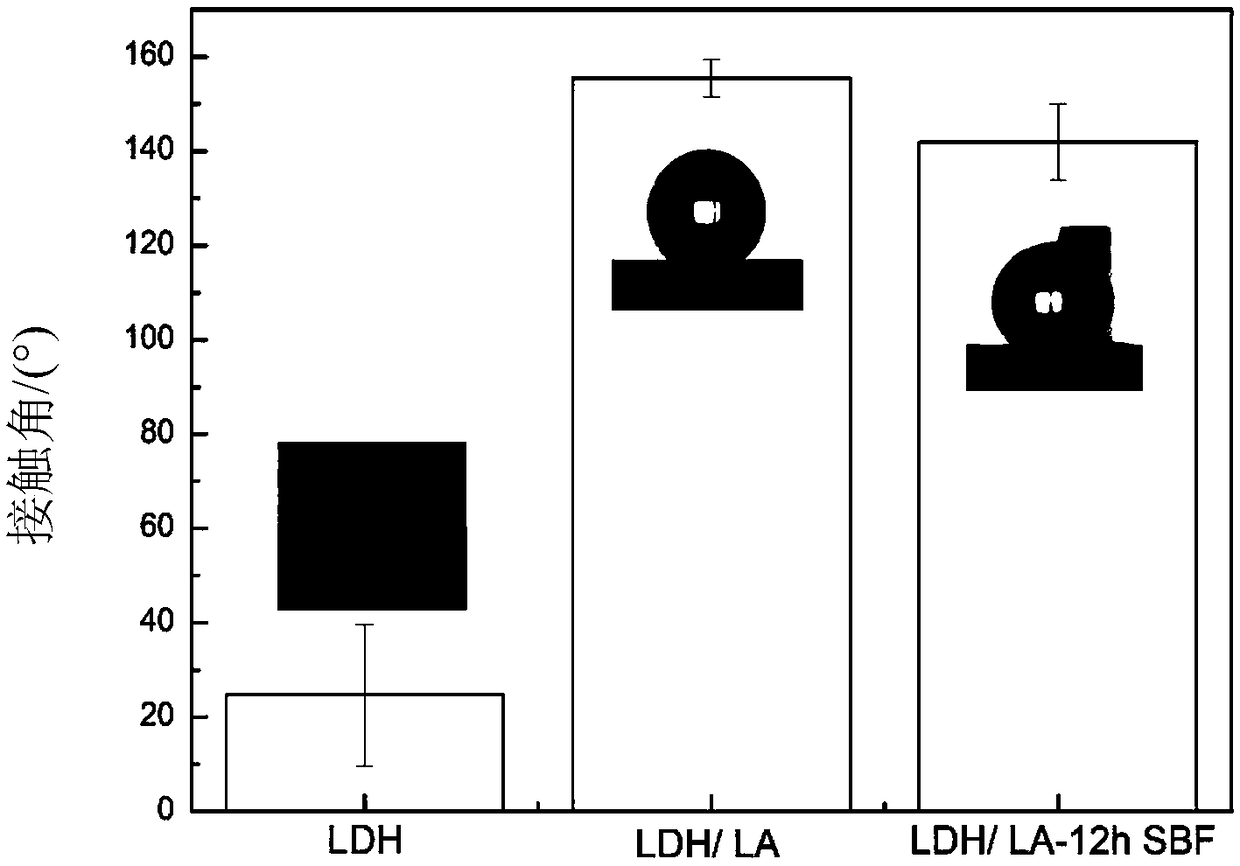

[0036] A method for regulating the structure of a superhydrophobic hydrotalcite-like film on the surface of a magnesium alloy by an electric field and the hydrotalcite-like film.

[0037] (1) Pretreatment of the surface of the biological magnesium alloy to remove the oxide layer and other impurities on the surface of the biological magnesium alloy: After the magnesium alloy sample is roughly ground on the metallographic pre-grinder, it is then polished step by step with W20 and W10 sandpaper, Put the ground magnesium alloy sample into the alcohol solution and ultrasonically clean it for 5 minutes, and then ultrasonically clean it in deionized water for 5 minutes;

[0038] (2) In situ growth of hydrotalcite-like film on the surface of biological magnesium alloy: firstly, the pretreated magnesium alloy substrate is used as the working electrode, and the platinum electrode is used as the counter electrode, which are respectively connected to the anode and cathode connections of th...

Embodiment 2

[0041] Same as Example 1, the difference is: In step (2), the working electrode and the counter electrode are soaked in solution B, the temperature of solution B is 80°C, the pulse power supply is turned on, and the power supply is turned off after 6 hours of operation, the working electrode is taken out and the blower is cleaned. dry; the bio-magnesium alloy with hydrotalcite-like film in step (3) is placed in lauric acid ethanol solution at 50°C and the molar concentration of solute is 0.04M, the pulse power supply is connected, the forward and reverse current values are 0.05A, soak 20min.

Embodiment 3

[0043] With embodiment 1, difference is: in the step (2), working electrode and opposite motor are soaked in solution A, and solution A is the Mn(NO of molar concentration 0.05M 3 ) 2 Saturated carbonic acid solution, the temperature of solution A is 60°C; the working electrode and counter electrode are then soaked in solution B, solution B is Mn(NO 3 ) 2 Sodium carbonate solution, turn on the pulse power supply, turn off the power after running for 4 hours, take out the sample and wash and dry; in step (3), the biomagnesium alloy with hydrotalcite-like film is placed in laurel In the acid ethanol solution, turn on the pulse power supply, the forward and reverse current value is 0.05A, soak for 30min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current density | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com